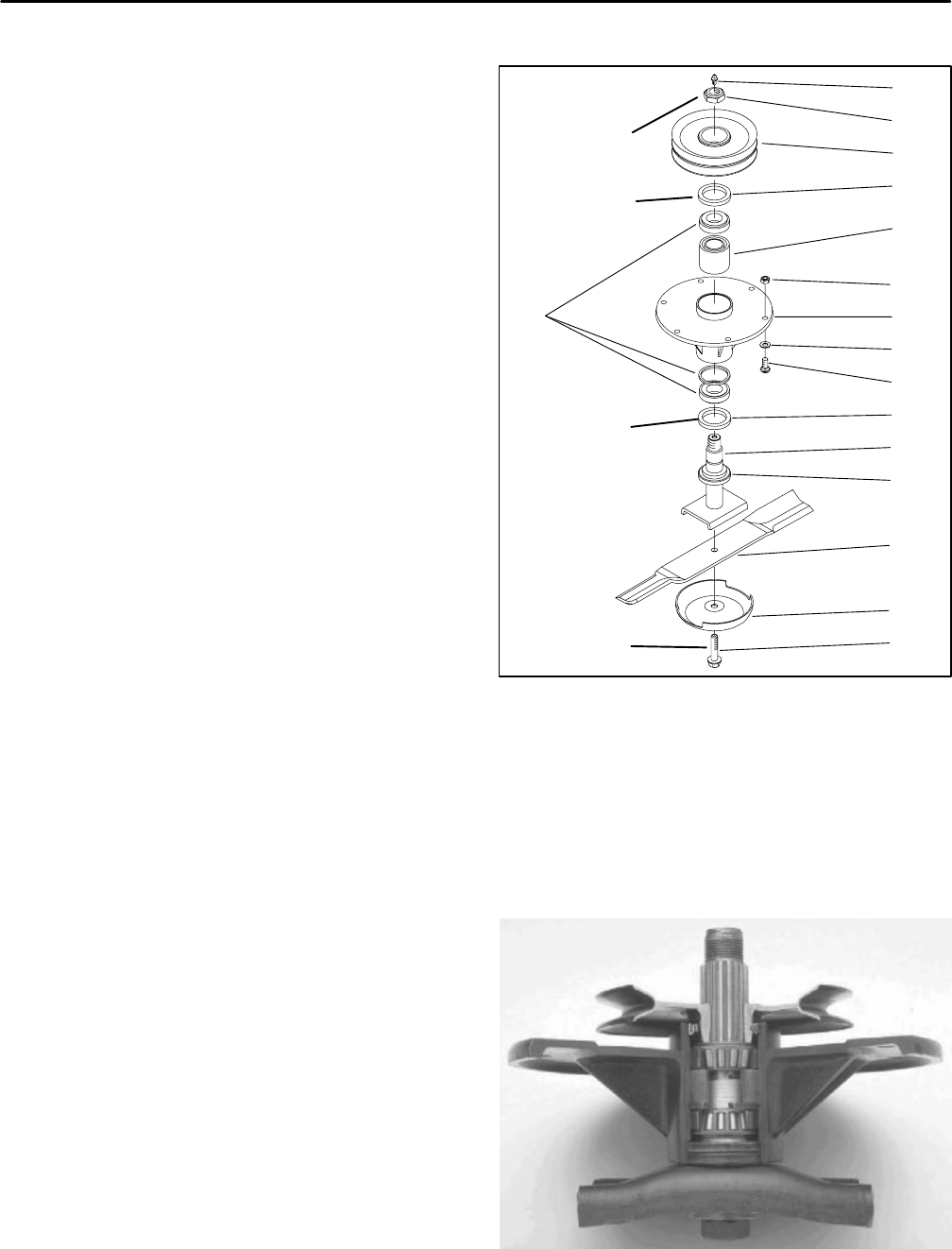

Blade Spindle Service

Removing Spindle Housing Assembly

1. Lower the cutting unit, shut the engine off and engage

the parking brake.

2. Remove deck covers from top of cutting unit. Release

belt tension. Remove belt from spindle to be serviced.

3. Start the engine and raise the cutting unit. Turn the

engine OFF and remove the key from the key switch.

Block up the cutting unit so it cannot fall accidentally.

4. Remove blade screw, flat washer, anti–scalp cup and

blade from spindle assembly.

5. Remove flange nuts and carriage bolts securing

spindle housing to deck. Slide spindle housing assem-

bly out the bottom of the cutting unit.

Disassembly

1. Remove lock nut retaining the spindle pulley on

spindle shaft. Slide pulley off of shaft.

2. Press the spindle shaft out of the spindle housing

using an arbor press. The bearing spacer remains on

the spindle shaft as the shaft is being removed.

3. Remove seals from spindle housing.

4. Allow the bearings and small thick spacer to fall out

of the spindle housing.

5. Using a punch and hammer, drive both of the bearing

cups out of the spindle housing. Also drive the large

spacer out of the housing.

6. A large snap ring is still inside the spindle housing and

it should remain there because it cannot be easily

removed.

IMPORTANT: If new bearings will be installed into a

used spindle housing that has the original snap ring

installed, discard the large snap ring that came with

the bearings because it is not needed. However,

new bearings with their matched spacer and snap

ring must always be installed when the spindle

housing is being replaced. Replacement bearings

are sold only with a matched snap ring and spacer

set. These parts cannot be purchased separately.

(12 – 15 Kgm)

(12 – 15 Kgm)

Install seal with

lip facing IN

Install seal with

lip facing OUT

85 – 110 ft–lb

85 – 110 ft–lb

1

2

3

4

6

7

8

15

9

5

4

10

11

12

13

14

Figure 26

1. Grease fitting 9. Screw

2. Lock nut 10. Spindle shaft

3. Pulley 11. Spindle shaft spacer

4. Oil seal 12. Blade

5. Spacer and bearing assy 13. Anti–scalp cup

6. Spacers – matched set 14. Blade screw

7. Lock nut 15. Flat washer

8. Spindle housing

Figure 27

84 inch Cutting Units

Page 9 – 16

Groundsmaster 3000/3000–D