SAE Straight Thread O–Ring Port – Non–adjustable

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Always replace the O–ring seal when this type of fit-

ting shows signs of leakage.

3. Lubricate the O–ring with a light coating of oil.

4. Install the fitting into the port and tighten it down full

length until finger tight.

5. Tighten the fitting to the correct flats from finger tight

(F.F.F.T.).

Figure 4

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

.25

6 (3/8 in.) 1.50 +

.25

8 (1/2 in.) 1.50 +

.25

10 (5/8 in.) 1.50 +

.25

12 (3/4 in.) 1.50 +

.25

16 (1 in.) 1.50 +

.25

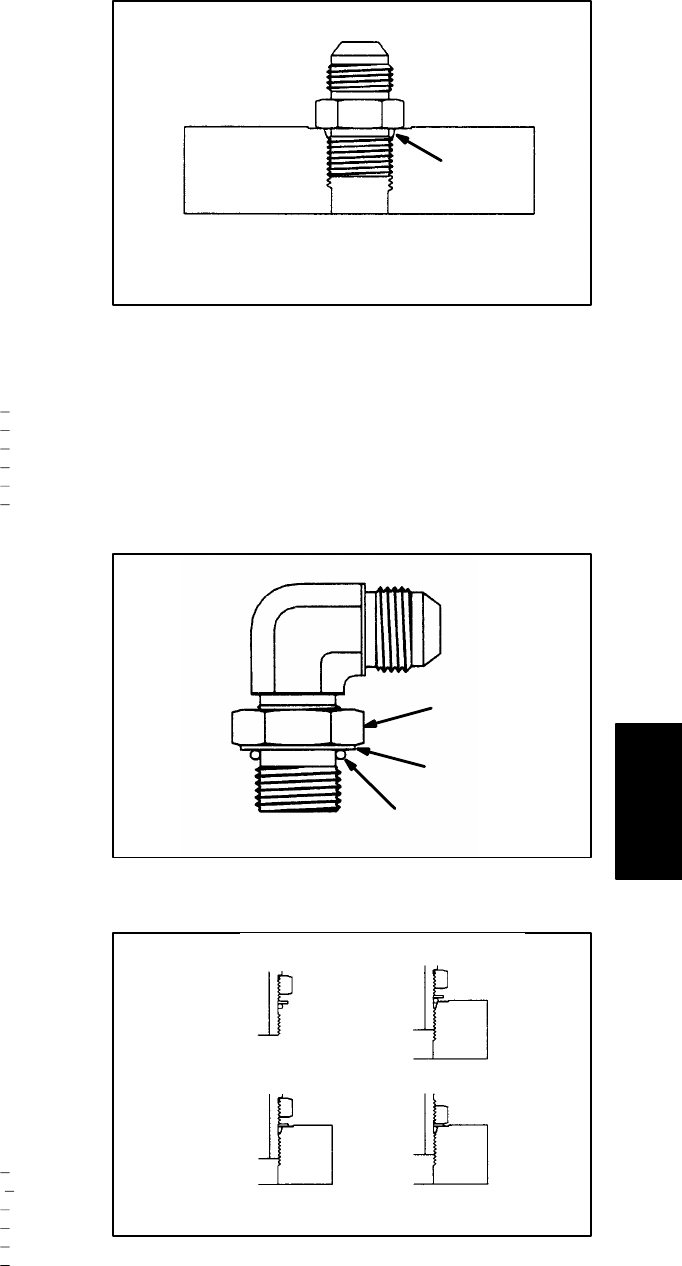

SAE Straight Thread O–Ring Port – Adjustable

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Always replace the O–ring seal when this type of fit-

ting shows signs of leakage.

3. Lubricate the O–ring with a light coating of oil.

Lock Nut

O–Ring

backup Washer

4. Turn back the jam nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

as possible (Step 1).

5. Install the fitting into the port and tighten finger tight

Figure 5

until the washer contacts the face of the port (Step 2).

6. To put the fitting in the desired position, unscrew it by

the required amount, but no more than one full turn

(Step 3).

Step 1

7. Hold the fitting in the desired position with a wrench

and turn the jam nut with another wrench to the correct

flats from finger tight (F.F.F.T.) (Step 4)

Size F.F.F.T.

Step 2

4 (1/4 in. nominal hose or tubing) 1.00 + .25

6 (3/8 in.) 1.50 +

25

8 (1/2 in.) 1.50 +

.25

10 (5/8 in.) 1.50 +

.25

12 (3/4 in.) 1.50 +

.25

16 (1 in.) 1.50 + .25

Figure 6

Step 4

Step 3

O–Ring

Hydraulic System

and Transaxle

Groundsmaster 3000/3000–D

Page 5 – 5

Hydraulic System