Temperature Gauge (GM 3000)

The temperature gauge can be tested using a new

gauge as a substitute or by the use of a DC voltage

source and a variable resistance box.

1. Connect the temperature gauge to the variable re-

sistance and DC voltage source (Fig. 34).

2. Adjust resistance until the gauge needle points to

following test points on the gauge (Fig. NO TAG):

A. At 150_F the resistance setting should be from

113 to 123 ohms.

B. At 180_F the resistance setting should be from

68 to 73 ohms.

C. At 240_F the resistance setting should be from

24 to 37 ohms.

3. Disconnect the voltage source, gauge, and variable

resistance.

S

I

G

+

–

12 VDC

BACK

240_F

180_F150_F

VARIABLE

RESISTANCE

Figure 55

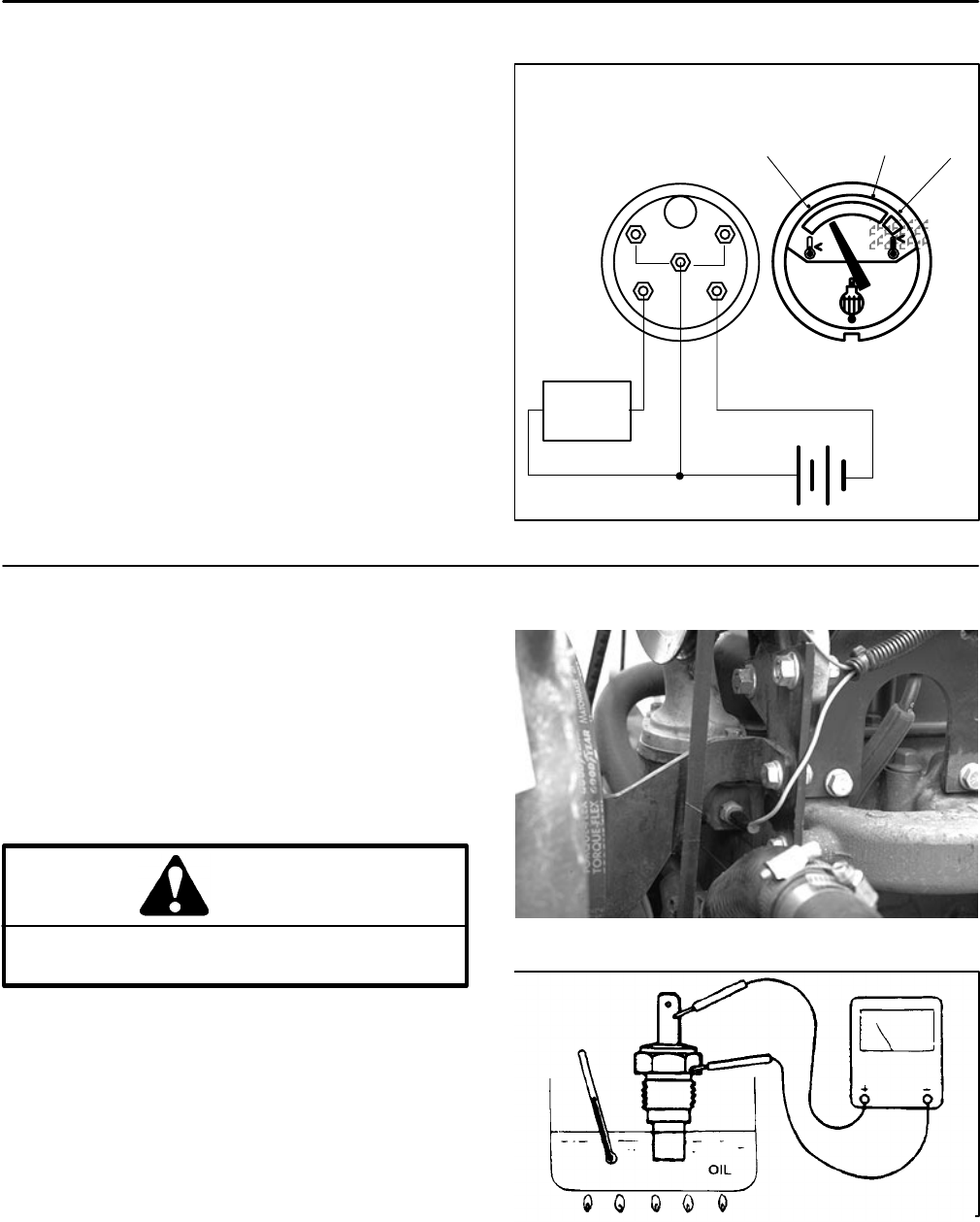

Thermistor (GM 3000)

The thermistor is located on the bottom right side of the

water pump, which is located on the rear end of the en-

gine block. It has a connector which a tan wire (Fig. 56).

1. Lower the coolant level in the engine and remove

the thermistor from the water pump.

2. Put the thermistor in a container of oil with a ther-

mometer and slowly heat the oil (Fig. 57).

CAUTION

Handle the hot oil with extreme care to prevent

personal injury or fire.

Figure 56

3. Check the resistance of the thermistor with a multi-

meter (ohms setting) as the temperature increases. The

following resistance readings should be indicated:

108 to 78 OHMS at 140_F (60_C)

59 to 51 OHMS at 212_F (99_C)

Figure 57

Electrical System

Page 6 – 30

Groundsmaster 3000/3000–D