Governor Adjustment

1. With engine shut off, move throttle control to FAST

position and open hood. Check between the throttle arm

and the stop on the carburetor base to make sure there

is 1/32” (0.8 mm). If gap is not correct, adjust throttle rod

by turning ball joint ends until gap is 1/32” (0.8 mm). If

gap is correct, proceed to step 2.

Engine must be running so final adjust-

ment of the governor can be performed.

guard against possible personal

hands, feet, face and other parts of the

body away from fan or other moving

parts.

WARNING

To

injury, engage parking brake and keep

2. Start engine and move throttle to SLOW position.

Allow engine to warm up to normal operating tempera-

ture.

3. Rotate throttle arm closed until it contacts stop.

4. Check idle speed and adjust carburetor idle speed

screw if necessary to attain 1350 +

50 rpm.

5. Release throttle arm, loosen jam nut on governor

low idle speed screw and adjust it to attain 1500 + 100

rpm.

6. Slowly move throttle to FAST position until engine

speed reaches 3150 +

100 rpm. Shut off engine. Adjust

high idle stop screw until it contacts speed control lever.

IMPORTANT: Do not over speed the engine because

the transmission could be damaged.

7. Move throttle rapidly from SLOW to FAST. The en-

gine should not surge. if engine surges, proceed to step

8.

8. Check V–belts from engine to governor pulley and

assure they are tight. If belts are loose, the engine will

surge. If belts are tensioned properly, loosen jam nut

that retains the anti–surge screw. Rotate screw clock-

wise 1/8 turn at a time until surging stops. Should gover-

nor continue to surge, check the following:

A. Carburetor too rich or too lean.

B. Binding in throttle linkage.

C. Governor worn internally.

IMPORTANT: Never rotate anti–surge screw in too

far so that speed of engine increases.

9. Bump the throttle lever with your hand so engine

speeds up momentarily. If governor is working properly,

engine speed should return to normal within one or two

surges of the governor. More than two surges of the gov-

ernor usually indicates than the anti–surge screw must

be turned in slightly more than it is. When adjustment is

correct, lock jam nut against governor body.

10. Check low and high idle speed to be sure there is no

change from the initial setting. If high idle speed has in-

creased, anti–surge has been turned into the governor

too far and it must be backed out. Then repeat the entire

adjustment procedure.

Note: If the throttle control on the instrument panel will

not stay in the FAST position during operation, remove

the panel cover and tighten the nut at base of throttle le-

ver assembly.

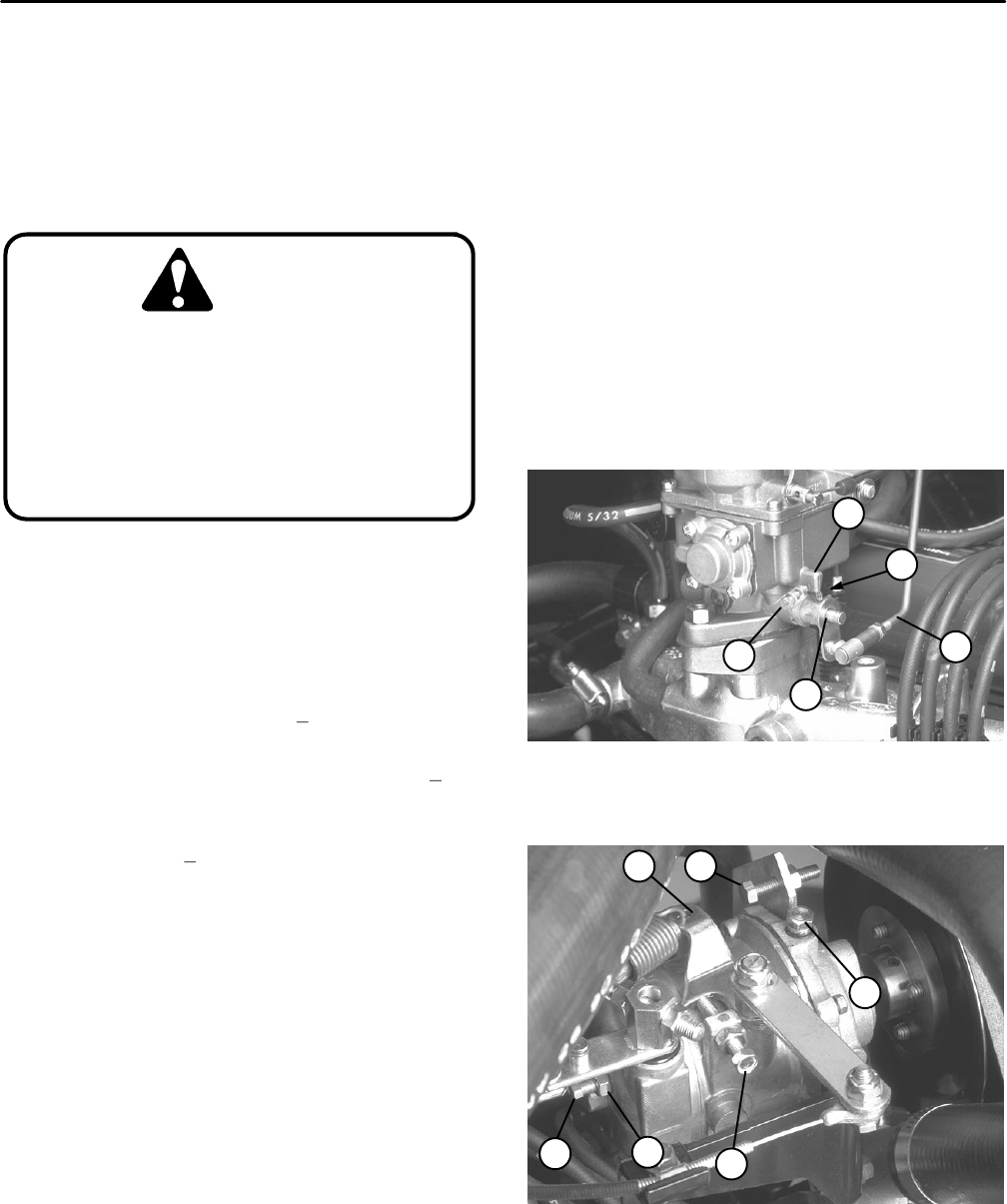

1

2

3

4

5

Figure 2

1. 1/32” (0.8 mm)

4. Stop

2. Throttle rod

5. Throttle arm

3. Carburetor idle speed screw

12

3

4

5

6

Figure 3

1. High idle stop screw

4. Anti–surge screw

2. Speed control lever

5. Low idle stop screw

3. Jam nut

Ford VSG–411 Engine

Page 3 – 4

Groundsmaster 3000