Blade Spindle Service

Disassembly

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Remove two cap screws that secure hydraulic motor

to the cutting unit. Remove hydraulic motor and O–ring

from deck (Fig. 30).

3. Start the engine and raise the cutting unit. Stop en-

gine and remove key from the ignition switch. Block up

the cutting unit so it cannot fall accidentally. If required

for easier service, remove cutting unit (see Disconnect

Cutting Unit From Traction Unit).

4. Remove cutting blade, anti–scalp cup and bolt (see

Cutting Blade Removal and Installation).

5. Remove cap screws and lock nuts securing spindle

housing to deck. Remove spindle assembly. Remove

spindle plate from under deck (Fig. 30).

6. Loosen and remove spindle nut from top of spindle

shaft (Fig. 31).

7. Press the spindle shaft out of the spindle housing us-

ing an arbor press. The shaft spacer remains on the

spindle shaft as the shaft is being removed.

8. Remove seals from spindle housing.

9. Allow the bearings, inside spacer and spacer ring to

fall out of the spindle housing.

10.Using a punch and hammer, drive both of the bearing

cups out of the spindle housing. Also drive the large

spacer out of the housing.

11. The large snap ring should remain inside the spindle

housing because it is difficult to remove.

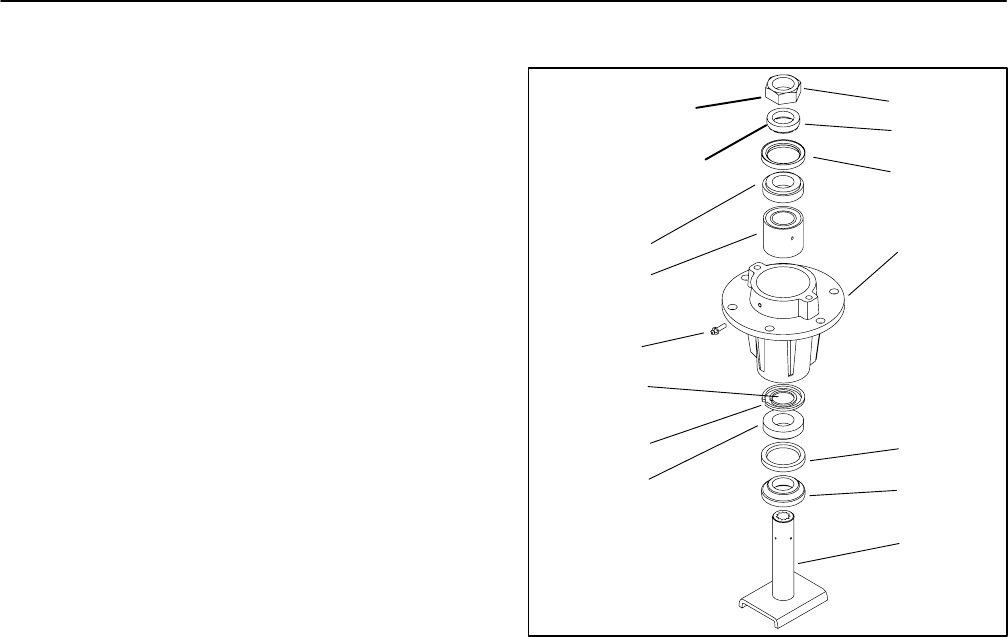

6

131 to 159 ft–lb

(178 to 216 N–m)

2

Chamfer side down

4

8

1

10

7

9

12

4

8

5

3

Figure 31

1. Spindle housing

7. Grease fitting

2. Seal spacer

8. Bearing

3. Spindle shaft

9. Spacer ring

4. Oil seal

10. Spacer set (2 piece)

5. Shaft spacer

11. Bearing

6. Spindle nut

12. Large snap ring

Contour 82 Cutting Unit

Page 10 – 20

Rev. C

Groundsmaster 3000/3000–D