SECTION 3 - LUBRICATION AND MAINTENANCE

3-18

EVERY 10 HOURS OR DAILY

OPERATION 6

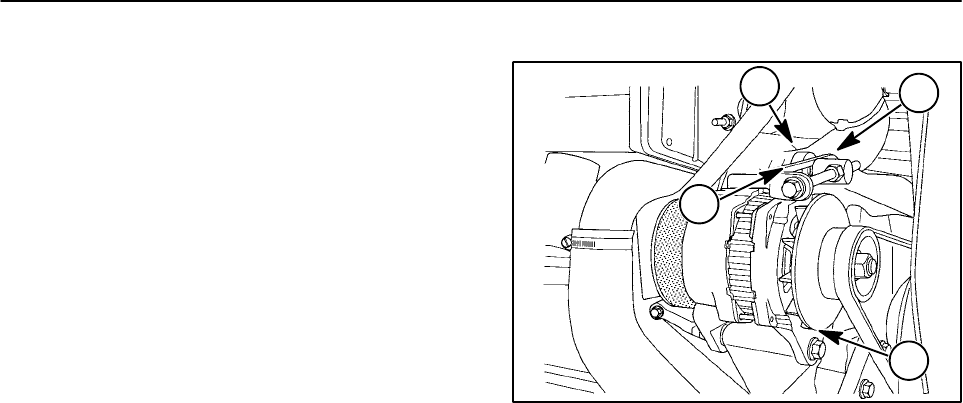

Check the Alternator Drive Belt Tension

2290, 2335, 2375 QSM11Engine

The QSM11 engines use a spring-loaded idler,

(N14 illustrated) to keep a constant tension on

the alternator belt. This is a shared drive using

the fan belt. See operation 3, for details on

checking tension.

2360, 2425 (N14) Engine

Use a belt tension gauge to check and/or adjust

belts, or use the firm thumb pressure and

deflection method. With firm thumb pressure, a

properly adjusted belt should deflect 0.8 mm

(1/32″) for each 25 mm (1”) of span between

pulleys. If the belt requires adjustment, use the

following procedure:

Loosen the pivot bolt, 1, which secures the

alternator to the engine. Loosen the adjuster

clamp bolt, 2, and locknut, 3. Adjust the belt

tension by tightening the adjuster bolt, 4. Torque

the adjuster clamp bolt to 79 N⋅m (58 ft. lbs.).

(Recheck the belt tension.) Torque the locknut to

79 N⋅m (58 ft. lbs.) and pivot bolt to 61 N⋅m (45 ft.

lbs.).

IMPORTANT: Do not adjust belt tension to full

value with the adjusting screw. Belt tension can

increase when the adjuster clamp bolt is

tightened and, therefore, reduce belt and

bearing life.

NOTE: 2360, and 2425 tractor models use the

same alternator adjustment bracket.

If the belt requires replacement, the adjustment

should be backed off all the way, and the belt

slipped up around thepulleys. Install the new belt

by reversing the procedure and tension it as

detailed above. Never pry a belt off a pulley as

damage to the pulley may result.

NOTE: The alternator drive belt is supplied by

Buhler Versatile. Contact your Buhler

Versatile dealer if a new belt is required.

NOTE: Refer to your Cummins Engine

Manual for more information regarding belt

replacement, wear guidelines, and pulley

alignment.

Figure 3-18

1

3

2

4