SECTION 2 - OPERATION

2-52

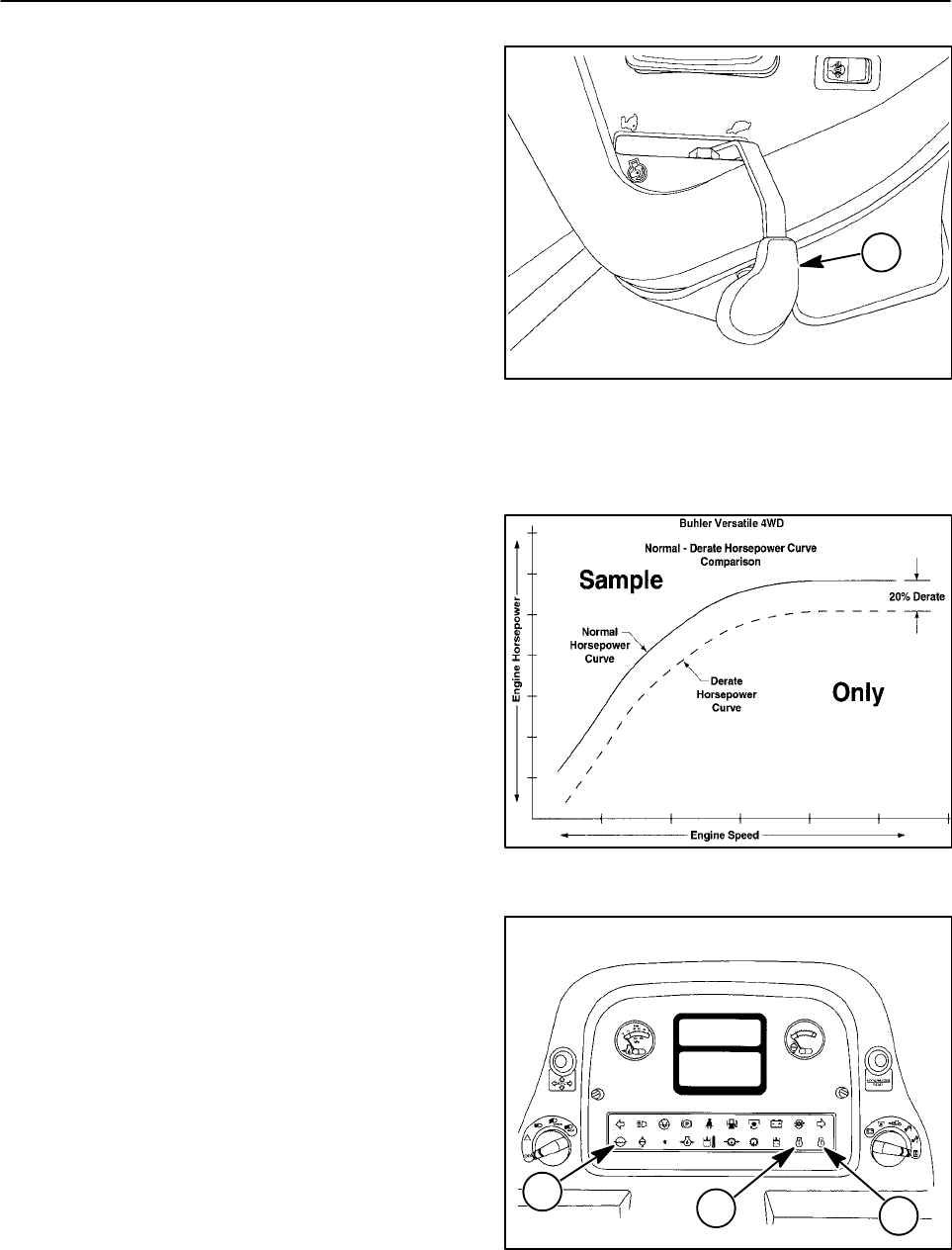

The throttle lever, 1, in the cab of the tractor is

attached to a potentiometer (POT) in the right

hand side console. The POT s ends an

electronic signal (via the tractor wire harness) to

the controller on the side of the engine, telling it

where to set the engine speed. By moving the

throttle lever, the POT signal is changed and the

module reacts accordingly to set engine speed

to match the lever position. During an engine

speed derate (engine speed reduced by the

engine control module to 1400 rpm), the module

will not recognize or react to a throttle position

above the 1400 rpm POT signal. If the throttle

lever is moved above the 1400 rpm position, the

engine will not speed up.

The engine control module controls the timing of

and the amount of fuel that is injected into the

engine via the electronic fuel injectors. This is

called fuel metering and is the basis of power

derate. Power derate will occur within a

specified time span (e.g. low engine oil

pressure) or will be gradual based on severity of

the alarm condition present on the tractor (e.g.

engine coolant temperature). The engine will

now perform to a modified horsepower curve

(20% less then maximum gross horsepower),

with the end result being that it will no longer pull

the same load at the same ground speed or at

the same working depth. The tractor may have

to be downshifted or the implement raised out of

the ground to continue operation (or both).

The Cummins engine control module is also tied

to three indicator lights on the warning light bar

of the EICS. The Module controls illumination of

these lights:

1. Engine Coolant Level

2. Yellow Engine Warning Light

3. Red Engine Warning Light

The EICS and Cummins control module

combine to protect the engine from damage by

informing the operator that a particular condition

exists using the lights, performance derate or

both lights and derate

.

1

Figure 2-78

Electronic Engine

Figure 2-79

2

1

3

Figure 2-80