Workman e2050/e2065

Transaxle and Brakes (Rev. B)

Page 4 – 8

Service and Repairs

Rear Wheels and Brakes

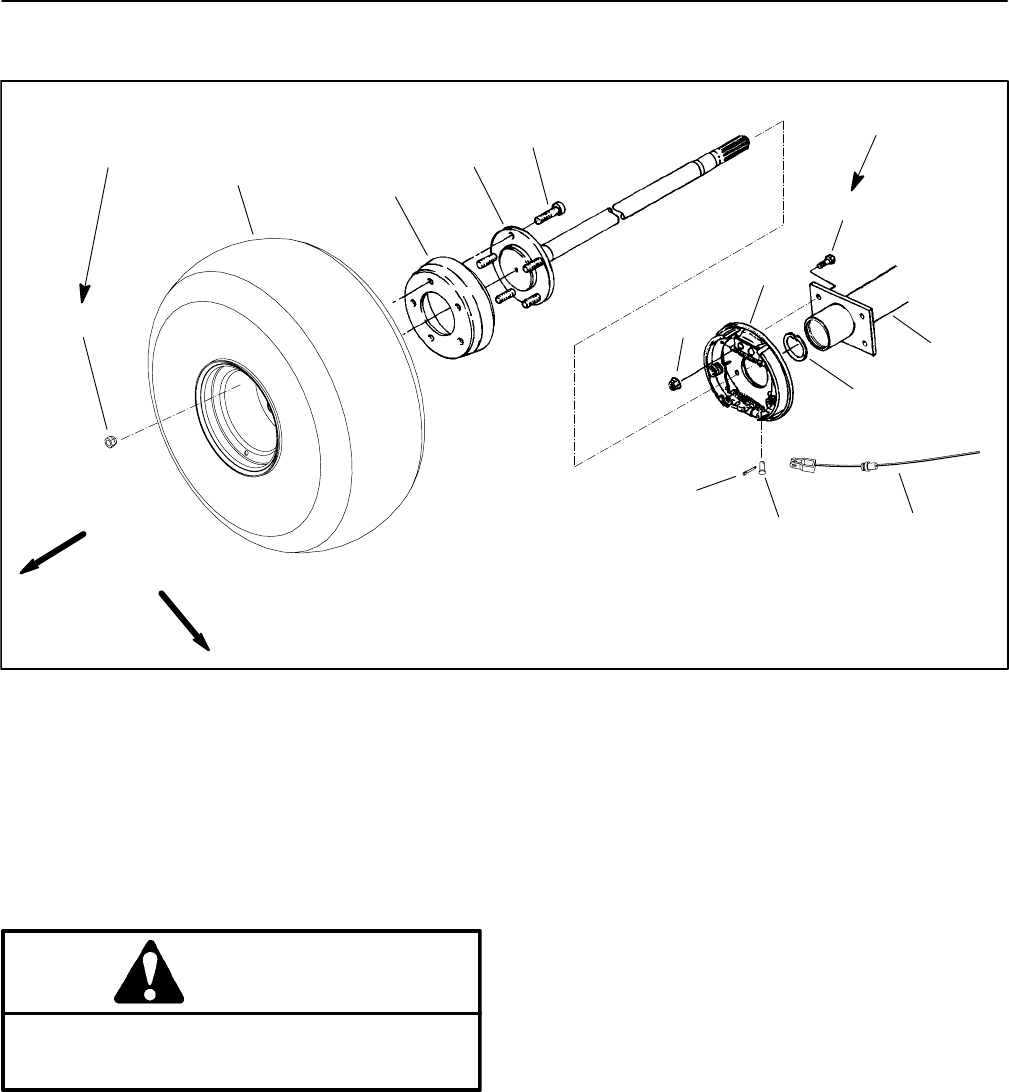

Figure 3

1. Lug nut (5 used per wheel)

2. Wheel assembly

3. Brake drum

4. Axle shaft

5. Wheel stud (5 used per wheel)

6. Flange head screw (4 used per brake)

7. Brake assembly (RH shown)

8. Nut (4 used per brake)

9. Cotter pin

10. Clevis pin

11. Brake cable (RH shown)

12. Retaining ring

13. Transaxle

13

45 to 65 ft–lb

(61 to 88 N–m)

FRONT

RIGHT

12

11

9

4

2

1

5

3

10

6

7

8

15 to 19 ft–lb

(20 to 26 N–m)

Removal (Fig. 3)

1. Park vehicle on a level surface, turn on/off switch

OFF and remove key from the on/off switch.

WARNING

Before jacking up the vehicle, review and follow

Jacking Instructions in Operator’s Manual and

Chapter 1 – Safety.

2. Chock wheels not being jacked up. Lift rear wheel off

the ground using a jack and place jack stand or blocks

beneath the rear frame to support vehicle.

NOTE: To remove brake drum, it may be necessary to

loosen brake cable adjustment or remove brake cable

from brake actuator lever.

3. Remove five (5) lug nuts, wheel assembly and brake

drum from the wheel hub.

4. Remove the axle shaft from the transaxle (see the

Spicer Off–Highway Components Model 12 (Electric)

Maintenance Manual at the end of this chapter).

5. If necessary, remove brake assembly as follows:

A. Remove cotter pin and clevis pin securing the

brake cable bracket to the brake actuator lever (Fig.

4).

B. On Workman e2065, clean hydraulic brake line

area of rear brake cylinder to prevent contamina-

tion. Loosen and disconnect hydraulic brake line

from wheel cylinder. Plug brake line and position it

away from wheel cylinder.

C. Remove four (4) cap screws and nuts securing

the brake assembly to the transaxle. Remove brake

assembly from the transaxle.