Workman e2050/e2065

Page 3 – 3

Electrical System (Rev. B)

General Information

The Workman e2050 and e2065 use a 48 volt DC elec-

trical system that is an isolated circuit. The vehicle frame

is not used for any ground connections.

The vehicle controller monitors operator and vehicle in-

puts to determine voltage to the traction motor. If a prob-

lem exists that will prevent normal vehicle operation, an

LED on the controller and the vehicle status light on the

dash panel will flash a fault code to assist in identifying

the problem.

After performing any repair on electrical components on

the vehicle, make sure that wiring is routed and secured

so as to prevent abrasion or contact with moving parts.

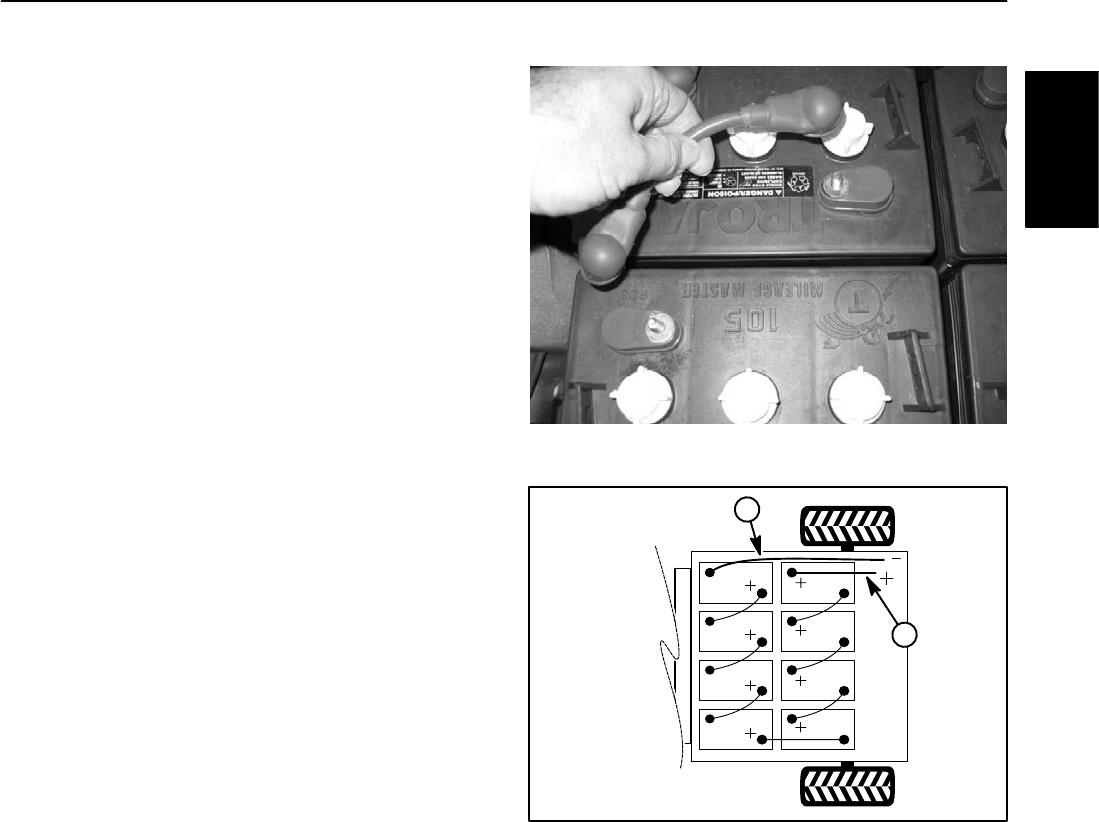

Opening Battery Circuit

To prevent allowing a current path through tools used

during vehicle electrical circuit repairs, remove one of

the battery cables from the battery pack as the first step

in any repair (Fig. 1). Once a cable has been removed,

the electrical system on the vehicle can be safely

worked on. Take care during repairs, however, to not al-

low tools or vehicle components to complete the battery

circuit that was opened with the cable removal.

Reattach the removed cable to the battery pack as the

last step in any repair. Secure cable on each battery ter-

minal with lock washer and nut. Torque nuts from 115 to

125 in–lb (13 to 14.1 N–m).

Battery pack cable routing is shown in Figure 2.

Figure 1

1. Negative cable to vehicle 2. Positive cable to vehicle

Figure 2

A

4

1

2

Electrical

System