Workman MD/MDX Drive TrainPage 5 -- 7

Adjustments

Adjust Ground Speed (Workman MD)

Workman MD models are equipped with a transaxle

governor. Adjust ground speed using the following pro-

cedure.

Vehicles operating at ground speeds greater than

the recommended speed will require further

distances to fully stop. Do not adjust ground

speed greater than specified.

WARNING

1. Park machine on a level s urface, stop engine and re-

move key from the ignition switch. R aise and support

cargo box.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 -- Safety.

2. Jack up rear of vehicle so both rear wheels are at

least 1 inch (25mm) off the ground. Support the rear axle

tubes on appropriate jack stands.

3. Chock front and rear of both front tires to prevent the

vehicle from moving.

4. Make sure that the shift lever is in the neutral posi-

tion.

5. Verify ground speed as follows:

A. Start engine and hold accelerator pedal to the

floor.

B. Verify driven clutch RPM with a tachometer. With

the accelerator pedal to the floor, the driven clutch

speed should be from 3550 to 3650 RPM.

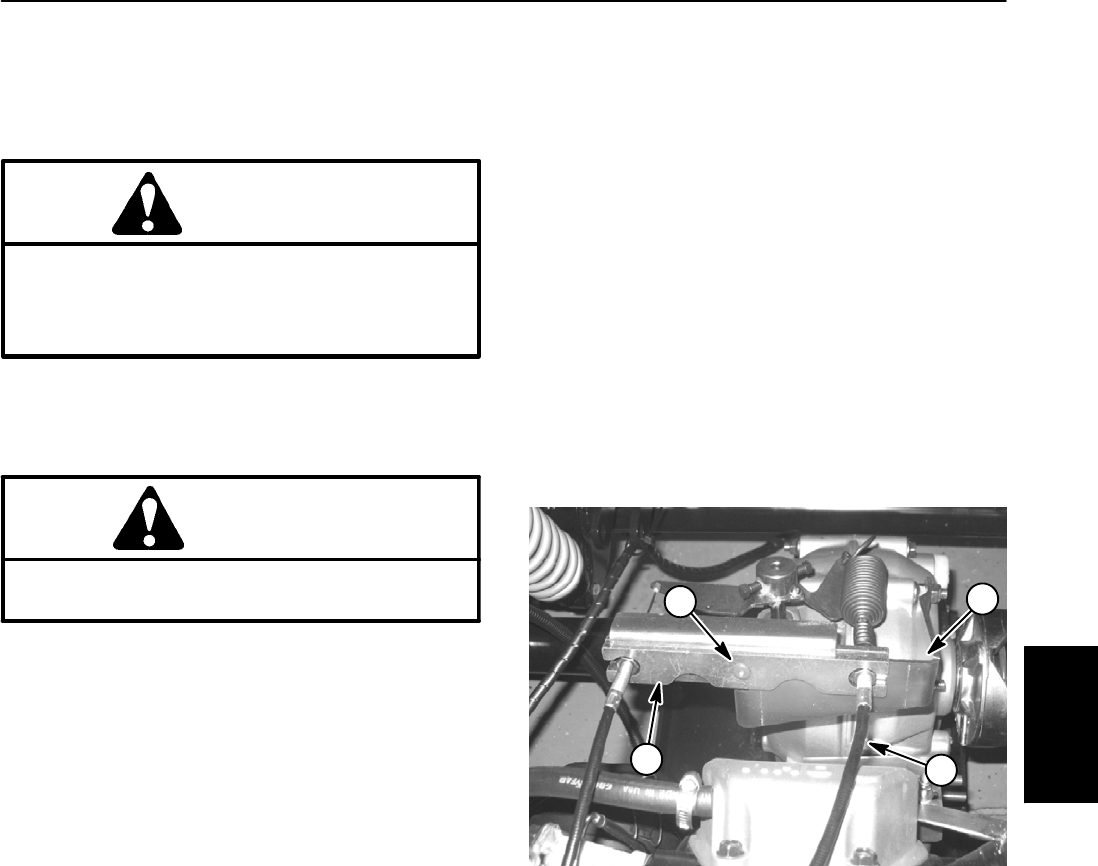

6. If ground speed adjustment is necessary, drill out an-

odized rivet and retain anti--tamper bracket for rein-

stallation (Fig. 8).

7. Adjust throttle cable (accelerator pedal to transaxle)

at the cable bracket until the correct driven clutch RPM

is obtained with the accelerator pedal fully to the floor

(Fig. 8).

8. Install anti--tamper bracketto the cable bracket using

a new anodized rivet (Toro P/N 99--7122) (Fig. 8).

9. Lower machine to ground. Lower and secure cargo

box.

NOTE: Ifunable to identify the driven clutch RPM,an al-

ternate method to verify ground speed would be to de-

termine the distance that the vehicle will travel on level

ground in three (3) seconds with the accelerator pedal

to the floor.The Workman MD should travel 62 feet (18.8

meters) in three seconds. If necessary, adjust ground

speed using steps 6 through 8 above.

1. Anodized rivet

2. Anti--tamper bracket

3. Throttle cable

4. Cable bracket

Figure 8

3

1

2

4

Drive Train