Workman MD/MDX Page 6 -- 23 Electrical System

IMPORTANT: Do not remove field coils unless they

are to be replaced.

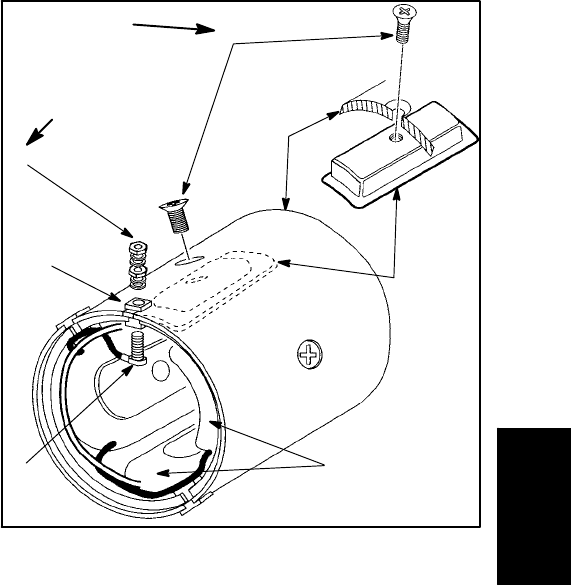

10.To remove field coils (Fig. 29):

A. Remove nuts from threaded terminal. Slide insu-

lator and terminal out of yoke.

B. Remove four (4) pole piece screws and pole sets

from the yoke. Remove field coils from the yoke.

11.Assemble starter/generator as follows:

A. Position field coil into yoke. Make sure both insu-

lators that look similar go into the slots marked F1

and F2. The different looking insulator goes into the

slot marked DF. Seat insulators into slots (Fig. 29).

IMPORTANT: Make sure field coil terminal wire

will not make contact with the armature.

B. Install terminals through wire connectors and in-

sulators. Secure flat washer, lock washer and nut

onto each terminal. Torque nuts from 43 to 52 in--lb

(4.9 to 5.9 N--m) (Fig. 29).

C. Position all four (4) pole pieces into the yoke. Se-

cure pole pieces with set screws. Torque screws to 9

ft--lb (12 N--m) (Fig. 29).

D. Position bearing retainer onto the output shaft of

the armature. Press new ball bearing onto the shaft

being careful not to damage the retainer.

E. Press new ball bearing onto the commutator end

of the armature shaft.

F. Position front end cover onto the output shaft. Se-

cure bearing retainer to the end cover with flat wash-

ers, lock washers and screws. Torque screws from

35 to 43 in--lb (4.0 to 4.9 N--m).

G. Position armature carefully into the yoke. Make

sure not to damage field coils. Align front end cover

to the yoke with the locating pin.

IMPORTANT: When installing the commutator

end cover, make sure brushes do not contact the

commutator. Damage to the brushes may result.

H. Lift brush springs from the notch at the end of the

brushes while pulling the brushes out. Allow springs

to hold brushes out from the center (Fig. 25).

I. Position commutator end cover carefully to the

commutator and yoke. Align end cover to the yoke

with the locating pin.

J. Secure both end covers to the yoke with both

through bolts and flat washers. Torque bolts from 96

to 104 in--lbs (10.8 to 11.8 N--m).

K. Slide brushes into holders. Secure brushes by

positioning brush springs into the notch at the end of

the brushes (Fig. 27).

L. Install brush covers to the commutator end cover.

M. Position spacer and woodruff key onto the shaft.

Place pulley onto the shaft.

N. Secure pulley to the shaft with spring washer and

nut. Torque nut from 15 to 25 ft--lb (20 to 34 N--m).

1. Field coils

2. Nut and washers

3. Threaded terminal

4. Insulator

5. Set screw

6. Pole piece

7. Yoke

Figure 29

2

5

7

6

1

3

4

9 ft--lb

(12 N--m)

43 to 52 in--lb

(4.9 to 5.9 N--m)

Electrical

System