Rev. A

Workman MD/MDX Drive TrainPage 5 -- 5

Driven Clutch Operation

The operation of the driven clutch is affected by trans-

axle load. When the v ehicle is stopped, the drive belt is

held at the outer diameter of the driven clutch sheaves

from the pressure of the spring pushing the moveable

sheave against the fixed sheave and away from the

fixed cam.

Once the drive belt starts rotating, the driven clutch also

starts to rotate. With increasing speed of the drive

clutch, the drive belt begins to climb to the outer diame-

ter of the drive clutch sheaves. This increases the ten-

sion on the drive belt, and forces the moveable sheave

of the driven clutch to move away from the fixed sheave

against the pressure of the spring. As the belt tightens

and the sheaves open up,the drive belt rides lower in the

driven clutch sheaves.

With increased load to the transaxle, the fixed cam re-

sists forward movement relative to the moveable

sheave and drive belt. Torque from the drive belt and

spring pressure moves the moveable sheave up the

ramp of the fixed cam. The drive belt becomes posi-

tioned closer to the outer diameter of the driven clutch

sheaves.

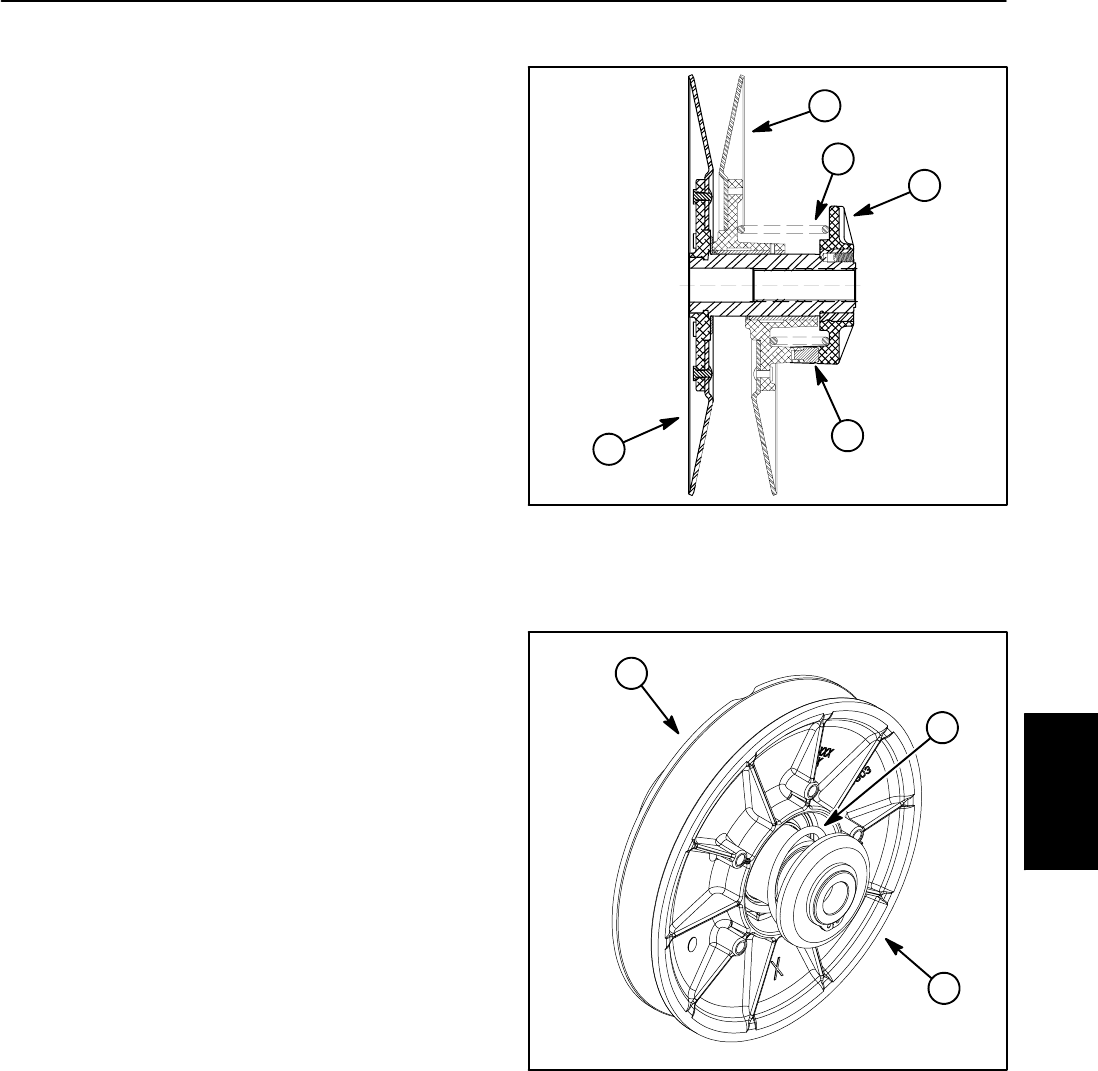

On vehicles with a serial number below 310000000,

three (3) sets of buttons on the driven clutch moveable

sheave providea low friction surfaceon which the move-

able sheave can slide on the ramp of the fixed cam (Fig.

4).

On vehicles with a serial number above 310000000, a

fixed cam on the driven clutch moveable sheave rotates

on a pair of rollers in the fixed sheave base to allow low

friction movement of the moveable sheave (Fig. 5).

1. Moveable sheave

2. Ramp (fixed cam)

3. Button

4. Fixed sheave

5. Spring

Figure 4

2

1

4

3

5

1. Moveable sheave

2. Fixed sheave

3. Spring

Figure 5

2

1

3

Drive Train