Workman MD/MDXPage 6 -- 10Electrical System

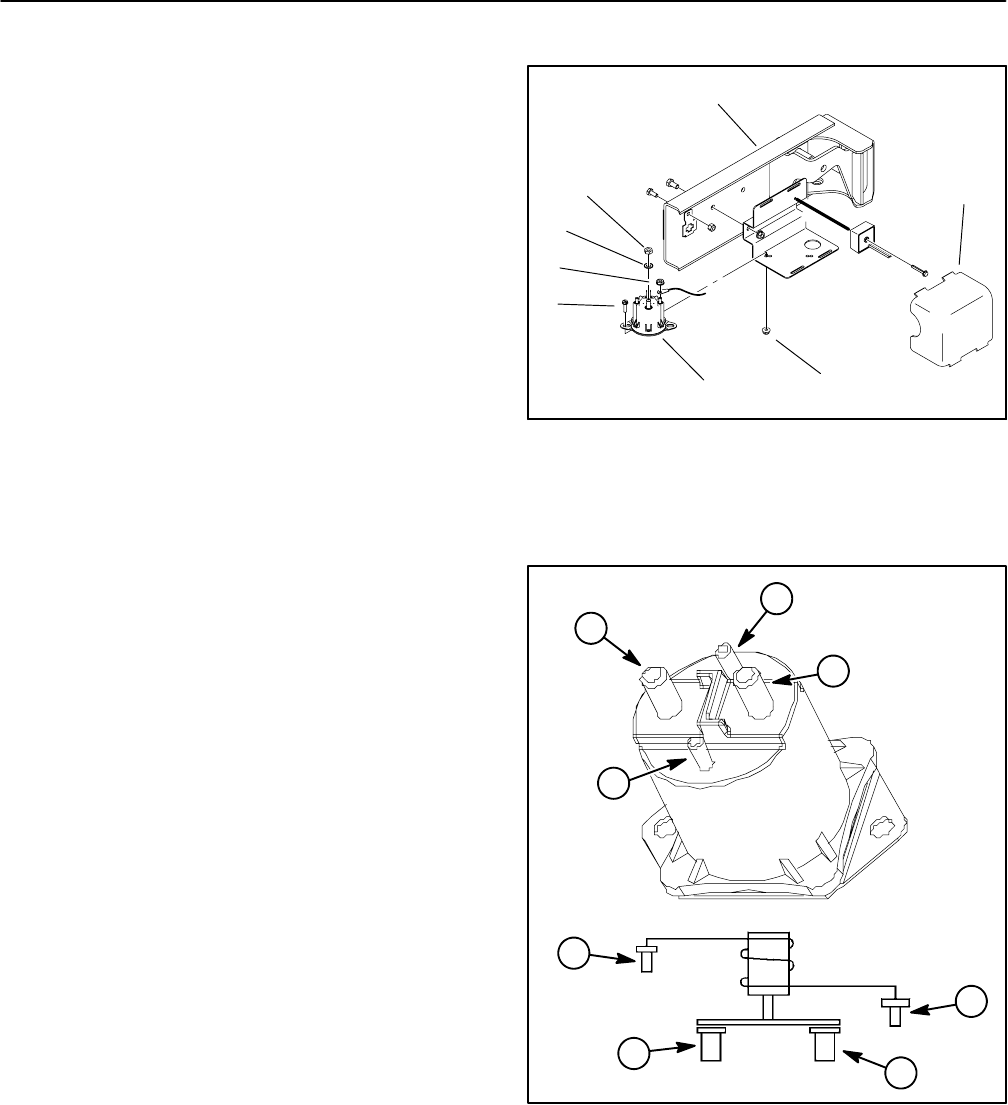

Start/Run Solenoid

The start/run solenoid provides a current path between

starter/generator and the vehicle electrical circuits. This

solenoid is energized when the ignition switch is ON and

the accelerator pedal is depressed. The solenoid is at-

tached beneath the cargo box to a bracket on the right

hand side of the rear frame (Fig. 8).

Testing

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from the measured value of the component you are

testing.

1. Place machine shift lever in the NEUTRAL position.

Apply parking brake. Make sure engine is off.

2. Raise cargo box and secure with prop rod. Gain ac-

cess to start/run solenoid by removing the electrical cov-

er.

3. Disconnect negative (black) cable from battery and

then disconnect positive (red) cable (see Battery Ser-

vice in the Service and Repairs section of this chapter).

4. Note wire connector locations on start/run solenoid

for assembly purposes. Disconnect wire harness con-

nectors from solenoid.

5. Apply 12 VDC directly across the solenoid coil posts

(steel). The solenoid should click as the solenoid coil is

energized. Make sure resistance across the main con-

tact posts (copper) is less than 1 ohm.

6. Remove voltage from solenoid coil posts. The sole-

noid should c lick as the solenoid coil is de--energized.

Make sure resistance across the main contact posts is

infinite ohms.

7. Resistance across the solenoid coil posts (steel)

should be approximately 13.5 ohms.

8. Replace start/run solenoid if necessary.

9. Connect electrical connections to solenoid: positive

battery cable and wire to fuse block on one main contact

post and starter/generator cable andwire to regulator on

the other main contact post. Connect battery cables.

Make sure to connect positive (red) cable first and then

connect negative (black) cable.

NOTE: Voltage is supplied to the solenoid on the Work-

man whenever the key is in the ON position and the ac-

celerator pedal is depressed.

1. Electrical cover

2. Flange nut (2 used)

3. Start/run solenoid

4. Screw (2 used)

5. Nut (2 used)

6. Lock washer (2 used)

7. Nut (2 used)

8. Rear frame

Figure 8

7

4

5

3

2

6

1

8

Figure 9

WIRING

DIAGRAM

1. Main posts (copper)

2. Solenoid posts (steel)

1

2

1

1

2

2

2

1