Workman MD/MDX Page 7 -- 21 Chassis

Pivot Yoke Removal (Fig. 11 and 12)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

2. Remove cargo box from the rear frame (see Cargo

Box Removal in this section).

3. Remove seat base from the front frame (see Seat

Base Removal in this section).

WARNING

Make sure all tires are chocked to prevent the

machine from moving. Beforeremoving the pivot

yoke, make sure front and rear frames are

supported with jack stands. Support both the

front and back of each frame.

4. Remove four (4) cap screws and flat washers secur-

ing the pivot yoke to the rear frame.

5. Remove cap screw and hardened washer securing

the pivot yoke to the front frame tab.

WARNING

Support pivot yoke while removing it from the

front frame to prevent dropping and causing

serious injury and damage to the machine.

6. Remove four (4) flange head screws and flanged

lock nuts securing the pivot yoke to the front frame. Re-

move pivot yoke from the machine.

Pivot Yoke Installation (Fig. 11 and 12)

WARNING

Support pivot yoke while installing it to the front

frame to prevent dropping and causing serious

injury and damage to the machine.

1. Position pivot y oke to the front frame so the diamond

pattern faces up. Secure yoke to front frame with four (4)

flange head screws and flanged lock nuts. Tighten lower

two (2) fasteners first, then tighten upper two (2) fasten-

ers.

2. Secure pivot yoke to the front frame tab with cap

screw and hardened washer. Torque cap screw from

240 to 290 ft--lb (326 to 393 N--m).

3. Secure pivot yoke to the rear frame with four (4) cap

screws and flat washers.

4. Install seat base to the front frame (see Seat Base

Installation in this section).

5. Install cargo box to the rear frame (see Cargo Box

Installation in this section).

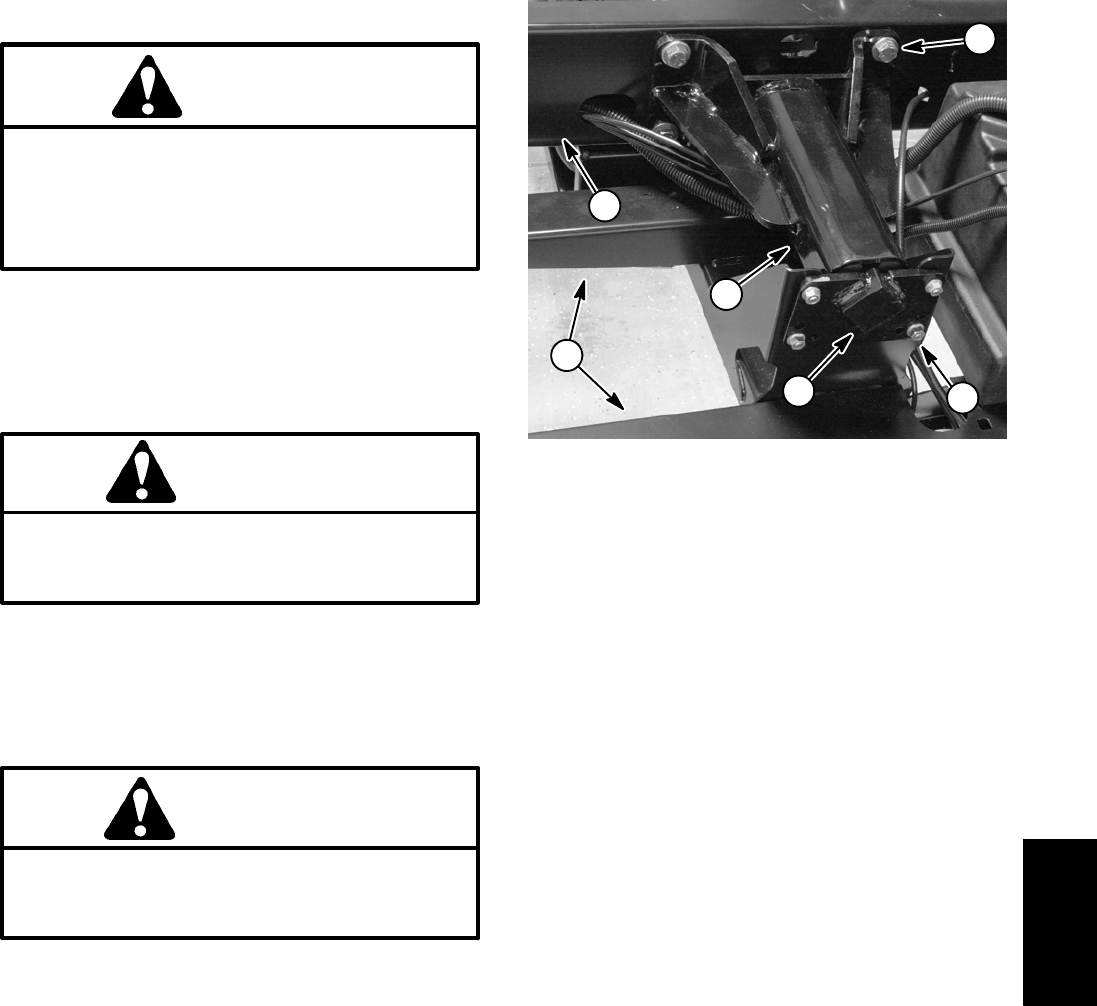

1. Cap screw & flat washer

2. Pivot yoke

3. Rear frame

4. Flange lock nut

5. Front frame

6. Diamond pattern

Figure 12

3

2

1

6

5

4

Chassis