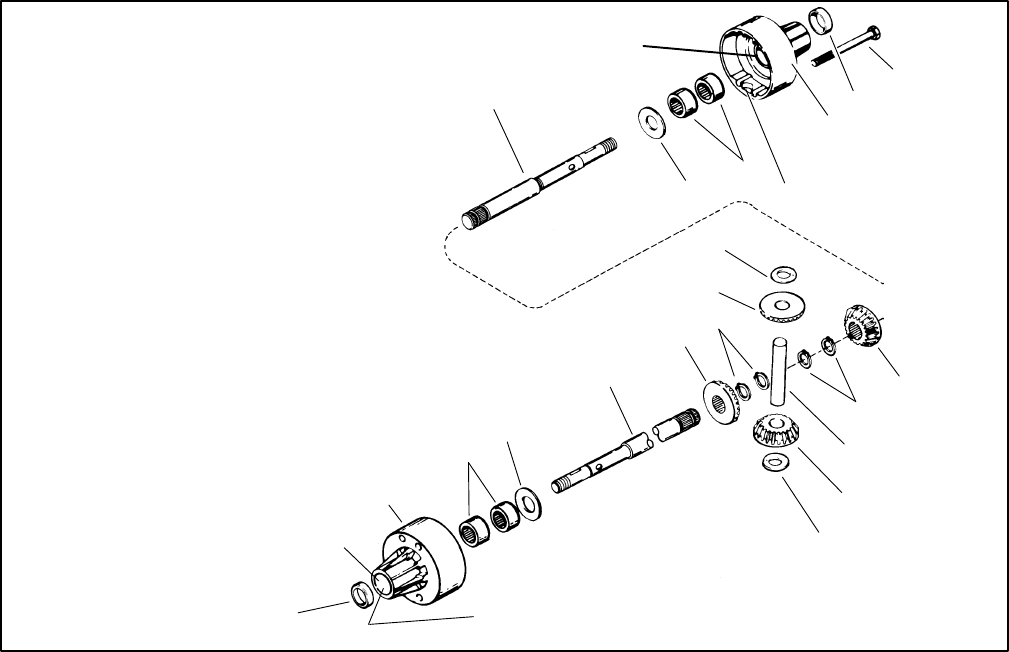

Greensmaster 1000/1600Traction and Reel Drive Systems Page 4 – 26

1. Flanged hex head screw

2. Differential carrier housing

3. Differential carrier housing

4. Axle (long)

5. Axle (short)

6. Bevel gear

7. Pinion

8. Drive pin

9. Thrust washer

10. Washer

11. Retaining ring

12. Needle bearing

13. Oil seal

Figure 43

2

4

5

6

7

9

10

11

1

12

13

6

7

8

9

10

11

12

13

3

BEARING RECESS (INBOARD)

0.125 TO 0.140 inch

(3.18 to 3.56 mm)

BEARING RECESS (OUTBOARD)

0.150 to 0.170 inch

(3.81 to 4.32 mm)

SEAL RECESS

0.030 TO 0.045 inch

(0.76 to 1.14 mm)

INSET FOR DRIVE PIN

Note: Individual parts to the differential assembly can

be obtained from your local Peerless Dealer/Distributor.

Disassembly (Fig. 43)

1. Clean outside of the differential assembly. Make

sure keys are removed from the axles. Remove all burrs

from the keyways and holes of the axles.

2. Remove four flanged hex head screws from the dif-

ferential carrier housings. Separate both housings be-

ing careful not to drop the drive pin and pinion gears.

3. Pull each differential carrier housing from its axle

and remove washer.

4. Remove both retaining rings from each axle. Sepa-

rate the bevel gears from each axle.

Note: The differential carrier housings come as-

sembled with both bearings and oil seal. It may be more

economical to replace the both housings rather than re-

pair them. If the needle bearings are damaged, it is rec-

ommended to replace all bearings in each housing.

5. If needle bearings are damaged, press both bear-

ings and oil seal out of each differential carrier housing.

6. Remove both thrust washers and bevel gears from

the drive pin.

7. Clean all parts so they are free of dirt and debris. Re-

place any worn, chipped, bent, or cracked parts.

Assembly (Fig. 43)

1. If needle bearings are being replaced, press both

new bearings and new oil seal into each differential car-

rier housing as follows:

A. Press bearing into the inboard side of the of each

housing. The bearing should be recessed 0.125 to

0.140 inch (3.18 to 3.56 mm).

B. Press bearing into the outboard side of the of

each housing. The bearing should be recessed

0.150 to 0.170 inch (3.81 to 4.32 mm).

C. Press oil seal into the outboard side of the of

each housing. The oil seal should be recessed

0.030 to 0.045 inch (0.76 to 1.14 mm).

D. Pack all bearings with molybdenum disulfide

grease.