Greensmaster 1000Grooming Reel Kit Page 8 – 12

Clutch Assembly

CAUTION

Do not use your hand to prevent the cutting

reel from turning while servicing; this can

result in personal injury. Insert a block of

hard wood into the front of the cutting unit

between the reel blades to prevent the reel

from turning.

Removal

1. Park mower on a level surface. Make sure engine

is OFF. Remove high tension lead from the spark plug.

2. Loosen set screws in the clutch knob. Remove

clutch knob and poly washer from the clutch assembly

(Fig. 6).

3. Remove three socket head cap screws and wash-

ers, then remove belt cover (Fig. 7).

4. Loosen socket head cap screw on idler block. Pivot

idler to loosen drive belt and remove belt (Fig. 14).

5. Remove lock nut and flat washer from the shaft of

the clutch drive adapter. Pull clutch assembly off the

shaft of the clutch drive adapter (Fig. 6).

6. Remove clutch adapter from the reel shaft if neces-

sary (Fig. 15).

Disassembly (Fig. 6)

Note: The special screw and clutch pin were as-

sembled with Loctite 271. It might be necessary to apply

heat to these parts prior to disassembly.

1. Remove special screw, clutch pin, and compression

spring from the driver pulley.

2. Separate flange bushing, clutch release disc, and

both belleville washers from the driver pulley.

3. Inspect needle and roller bearings for damage. Re-

place bearings if worn or damaged.

Reassembly (Fig. 6)

1. Pack needle and roller bearings and the inside of

the driver pulley with No. 2 multipurpose lithium based

grease. Press both bearings into the driver pulley with

seal side out.

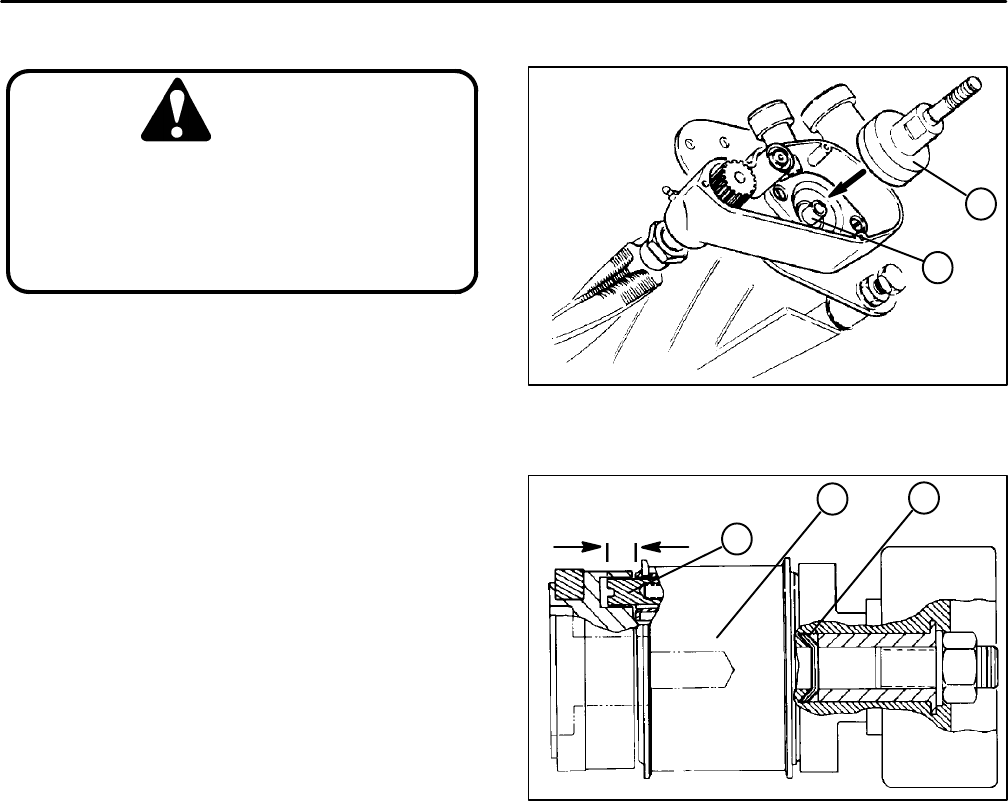

1. Clutch drive adapter 2. Reel shaft

Figure 15

1

2

1. Belleville washers

2. Clutch pin

3. Driver pulley

Figure 16

0.240 to 0.260 inch

(6.10 to 6.60 mm)

1

2

3

IMPORTANT: Keep grease off special screw

threads.

2. Apply a thick coat of grease to the special screw and

the cam surface of the clutch release disc.

IMPORTANT: Make sure belleville washers are

installed correctly (Fig. 16).

3. Assemble both belleville washers, clutch release

disc, and flange bushing to the driver pulley.

4. Insert special screw through the clutch release disk,

driver pulley and compression spring.

5. Apply Loctite 271 or equivalent to the threads of the

special screw. Secure compression spring to the special

screw with clutch pin. The clutch pin should extend out

from 0.240 to 0.260 inch (6.10 to 6.60 mm) the face of

the driver pulley when the pin is fully extended (Fig. 16).