Section 5

ENGINE DC CONTROL SYSTEM

The positive (+) battery cable (13) attaches to one of

the outer posts of the contactor along with Wire 13 for

the DC supply to the fuse (F1). The starter cable (16)

attaches to the remaining outer post. Attached to the

small 2 lugs are Wires 56 and 0. When the start/stop

switch is set to start, the circuit board delivers battery

voltage to the contactor coil via Wire 56. The contac-

tor energizes and its contacts close. Battery voltage

is then delivered from the positive battery cable,

across contacts and to the starter motor via Wire 16.

ENGINE GOVERNOR

A mechanical, all-speed governor is used on the

diesel engine. It is housed in the gear case. A fly-

weight movement is transmitted to the injection pump

control rack by way of the slider, control lever and

link. A spring is attached to the arm and the tension

lever. The spring regulates flyweight movement. By

changing the set angle of the governor lever, tension

on the tension lever spring is changed. In this man-

ner, engine speed can be regulated by the governor

lever.

The generators A/C output frequency is directly pro-

portional to engine speed. Low governor speed will

result in a reduced A/C frequency and voltage, and

high governor speed will produce an increased fre-

quency and voltage.

FUEL INJECTION PUMP

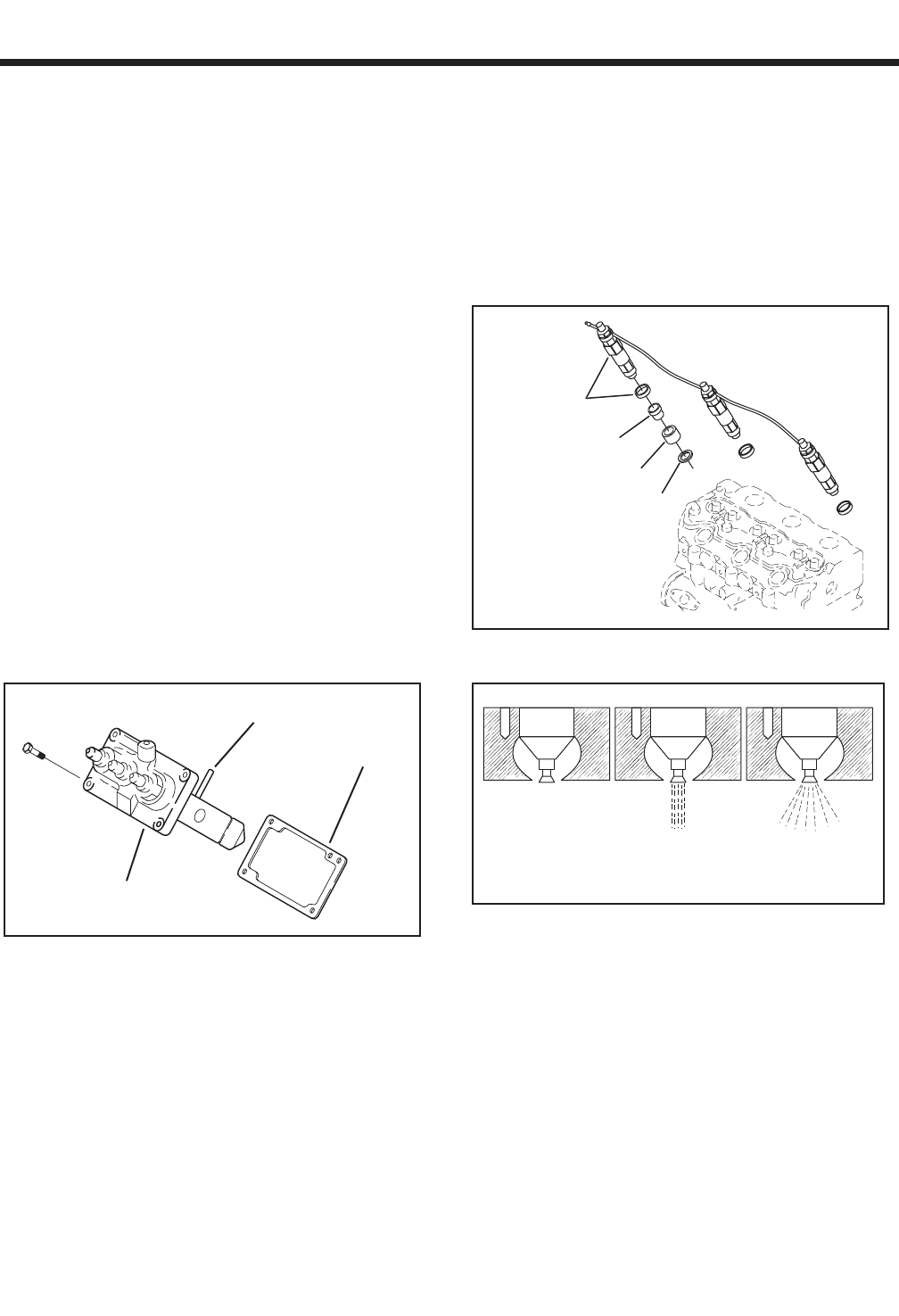

Figure 5-8. – Fuel Injection Pump

The fuel injection pump is mounted on the side of the

engine and rides on a three-lobe camshaft. The

lobes on the camshaft press the bottom of the pump,

which mechanically opens the fuel path to deliver fuel

to the fuel injectors. Timing for the fuel injector pump

is determined by the distance between the camshaft

lobes and the pump. This distance is regulated by

metal shims. If the shim space is incorrect, the fuel

pressure will be incorrect and combustion will not

occur. When the fuel injector pump is removed for

maintenance, be sure to reassemble with the same

number of shims. The engine governor controls the

fuel injector pump by linkage connecting the two.

FUEL NOZZLES/INJECTORS

Fuel supplied by the injector pump is delivered to the

nozzle holder and to the nozzle body. When fuel

pressure is sufficient to compress the spring, fuel is

supplied from the nozzle and into the combustion

chamber. Due to the high pressure of fuel being

ejected from the nozzle, there is no safe test. If faulty

fuel is suspected and a clogged injector pump was

diagnosed, the replacement of the injector nozzles

would be needed.

Figure 5-9. – Fuel Injectors

Figure 5-10. – Fuel Injector Nozzles

GLOW PLUGS

The glow plug consists of a thin coiled heat-wire that

is encased in sintered magnesium oxide powder and

enclosed by a stainless steel sheath. One end of the

wire is welded to the sheath and the other end is

welded to the center electrode. When voltage is

applied to the center electrode, it heats the heat-wire,

which in turn, heats the combustion chamber.

Glow plugs are connected in parallel. For that rea-

son, if one plug fails open, the other plugs will contin-

ue to operate. However, loss of one plug will

increase the possibility of the heat-wire melting open

in the remaining plugs.

VALVE

CLOSED

VALVE

OPEN

FULLY

OPEN

IN

J

E

C

T

OR

C

A

P

IN

S

ER

T

G

A

S

KE

T

CONTROL RACK

INJECTOR PUMP

SHIM

Page 27