Page 66

iQ Series, Ultrasonic Generator/Power Supply LS User’s Manual

Dukane Manual Part No. 403-574-01

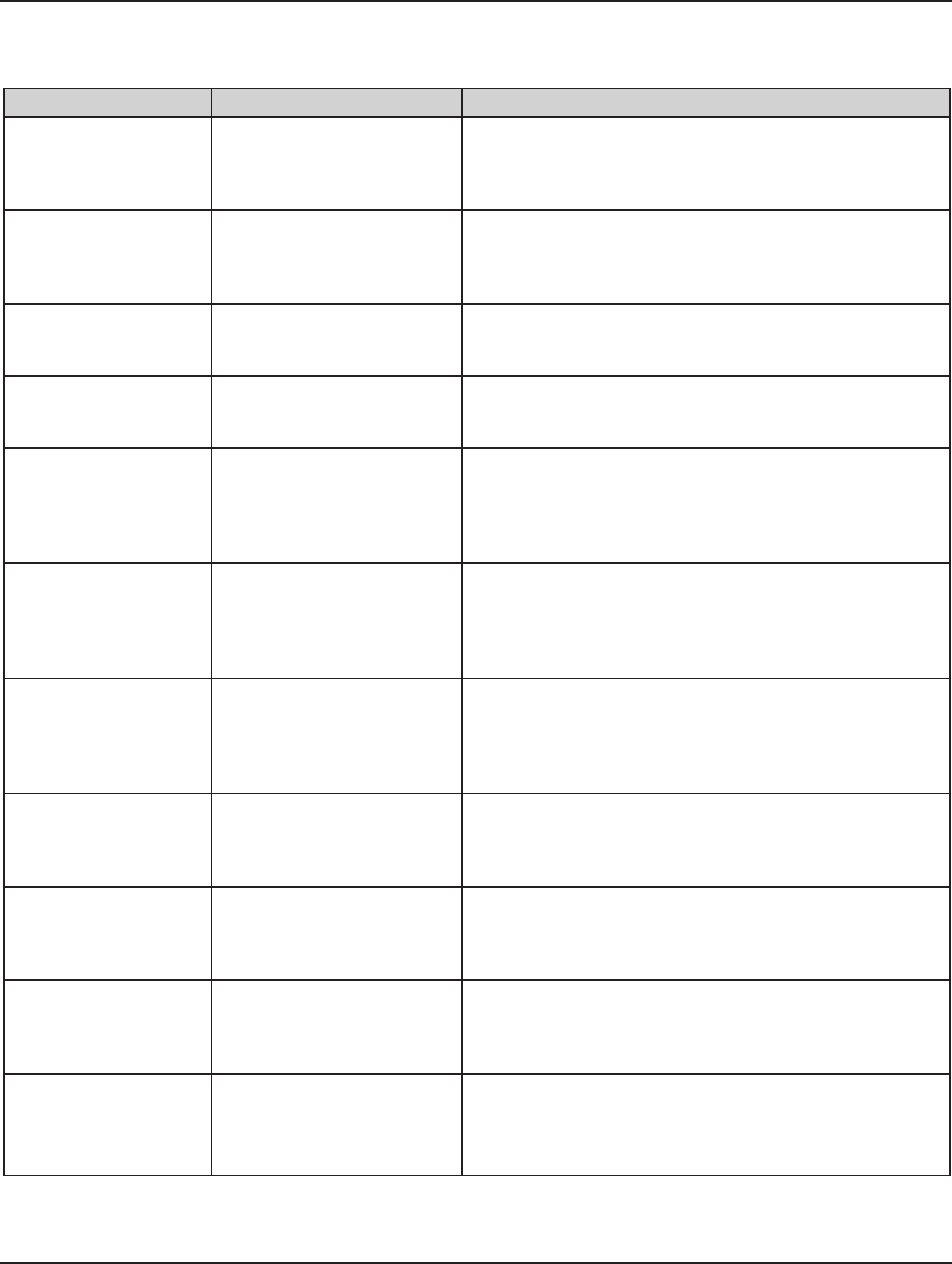

Pop-up Status Screens

System Status Signal Status Text Displayed System Status or Fault Explanation

Average Overload OVERLOAD - AVERAGE

AT X.XXX SECONDS

POWER ABOVE

GENERATOR RATING

An Average Overload fault tripped.

Output power exceeded rated wattage. Lower the welding

pressure or amplitude. Fault will reset when next weld

cycle starts.

Peak Overload OVERLOAD - PEAK

AT X.XXX SECONDS

CHECK STACK OR

COUPLING TO PART

A Peak Overload fault tripped.

Peak IGBT transistor current exceeded.

Caused by a severe frequency mis-match. Fault will reset

when next weld cycle starts.

End of Weld END OF WELD

SIGNAL

DETECTED

Automation activated End of Weld input.

This ends the weld, then hold time begins.

Status message is displayed a few seconds.

End of Cycle END OF CYCLE

SIGNAL

DETECTED

Automation activated the End of Cycle input.

This terminates the remaining weld cycle.

Status message is displayed a few seconds.

Over Temperature Fault SYSTEM OVER TEMP

DETECTED

System Over Temperature fault detected.

Check that cooling fan is operational. Check for dust

build-up in cooling channel.

Generator operation can continue after the system cools

down.

Overload Frequency OVERLOAD - FREQUENCY

AT X.XXX SECONDS

CHECK STACK AND CABLE

& RAMP UP TIME

Resonant frequency was not found.

Check for a defective stack component or for improper

stack assembly.

Check for a defective stack cable.

Fault will reset when next weld cycle starts.

Overload Frequency OVERLOAD - FREQUENCY

AT X.XXX SECONDS

CHECK FOR COUPLING

BETWEEN STACK AND

PART

Resonant frequency was lost during the cycle.

Check for a defective stack component or for improper

stack assembly.

Check for stack coupling to the xture.

Fault will reset when next weld cycle starts.

4-20 mA

Current Loop Fault

CURRENT LOOP FAULT

DETECTED

Remote control current loop fault detected.

Current loop current is less than 2mA.

Check current loop wiring and loop source.

This fault will set minimum amplitude level.

System Power Fault SYSTEM POWER FAULT

DETECTED

System AC line or power supply fault detected.

Check that AC line voltage level is normal.

Likely there will be no power for the front panel display.

Service may be required if this fault is displayed.

Front Panel Locked FRONT PANEL LOCKED

KEYPAD ENTRY NOT

ALLOWED

Front panel lockout input is activated.

Front panel changes are not allowed.

Warning pops-up if user attempts changes.

Status message is displayed a few seconds.

Empty Setup CURRENT SETUP

HAS NOT

BEEN PROGRAMMED

WELD CYCLE STOPPED

Warning text pops-up if a setup is empty.

User must program a valid welding setup.

Table 8-I Pop-Up Status Screens