NOTE: When properly installed, a light spring compres-

sion can be felt when pushing the cylinder block assem-

bly into the variable housing.

9. Position variable housing in a horizontal position.

Slide cylinder block assembly over the shaft engaging

splines. Make sure pistons and thrust plate remain in

place (Fig. 51).

10. Press needle bearing into the end cap. Bearing

must protrude 3/32 to 1/8 inch (2.38 to 3.18mm) from

face (Fig. 51).

11. Lubricate exposed face of the cylinder block with

clean hydraulic fluid (Fig. 51).

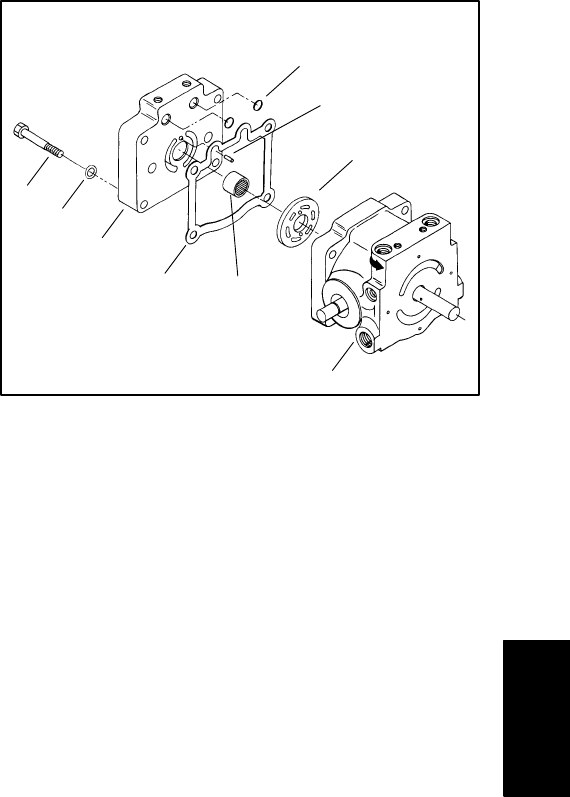

12. Position end cap to the variable housing. Lubricate

O–rings with clean hydraulic fluid. Position O–rings into

recessed holes of the end cap (Fig. 52).

13. Slide four cap screws through washers and end cap

holes. Place gasket onto the cap screws and the end

cap face (Fig. 52).

IMPORTANT: Make sure slotted and grooved side of

the valve plate is against the end cap face. The two

V–notches must face away from the end cap.

14. Insert locating pin into the end cap. Lubricate slotted

side of valve plate. Slip plate over pin and protruding

bearing (Fig. 52).

IMPORTANT: Make sure valve plate, gasket, and O–

rings stay in position when securing the end cap to

the variable housing.

15. Mate four cap screws to the variable housing (Fig.

52).

A. Tighten cap screws in an alternating pattern

while checking for proper assembly. Turn pump and

control shafts slowly while tightening cap screws.

B. Tighten screws until the housing and end cap are

completely pulled together.

C. Torque cap screws from 27 to 37 ft–lb (3.7 to 5.1

kg–m).

16. Assemble charge pump to variable housing (see

Charge Pump Assembly).

17. Install new lip seals to shaft and trunnion shafts (see

Shaft Seal Installation).

7

6

3

5

1

2

8

9

4

Figure 52

1. Cap screw (4 used)

6. Locating pin

2. Washer (4 used)

7. O–rings

3. End cap

8. End cap gasket

4. Variable housing

9. Needle bearing

5. Valve plate

Hydraulic

Systems

Sand Pro 2020/3020/5020 Page 4 – 55 Hydraulic System (Rev. A)