1-2 489 Generator Management Relay GE Multilin

1.1 OVERVIEW 1 INTRODUCTION

1

Power metering is a standard feature in the 489. The table below outlines the metered parameters available to the operator

or plant engineer either through the front panel or communications ports. The 489 is equipped with three fully functional and

independent communications ports. The front panel RS232 port may be used for setpoint programming, local interrogation

or control, and firmware upgrades. The computer RS485 port may be connected to a PLC, DCS, or PC based interface

software. The auxiliary RS485 port may be used for redundancy or simultaneous interrogation and/or control from a second

PLC, DCS, or PC program. There are also four 4 to 20 mA transducer outputs that may be assigned to any measured

parameter. The range of these outputs is scalable. Additional features are outlined below.

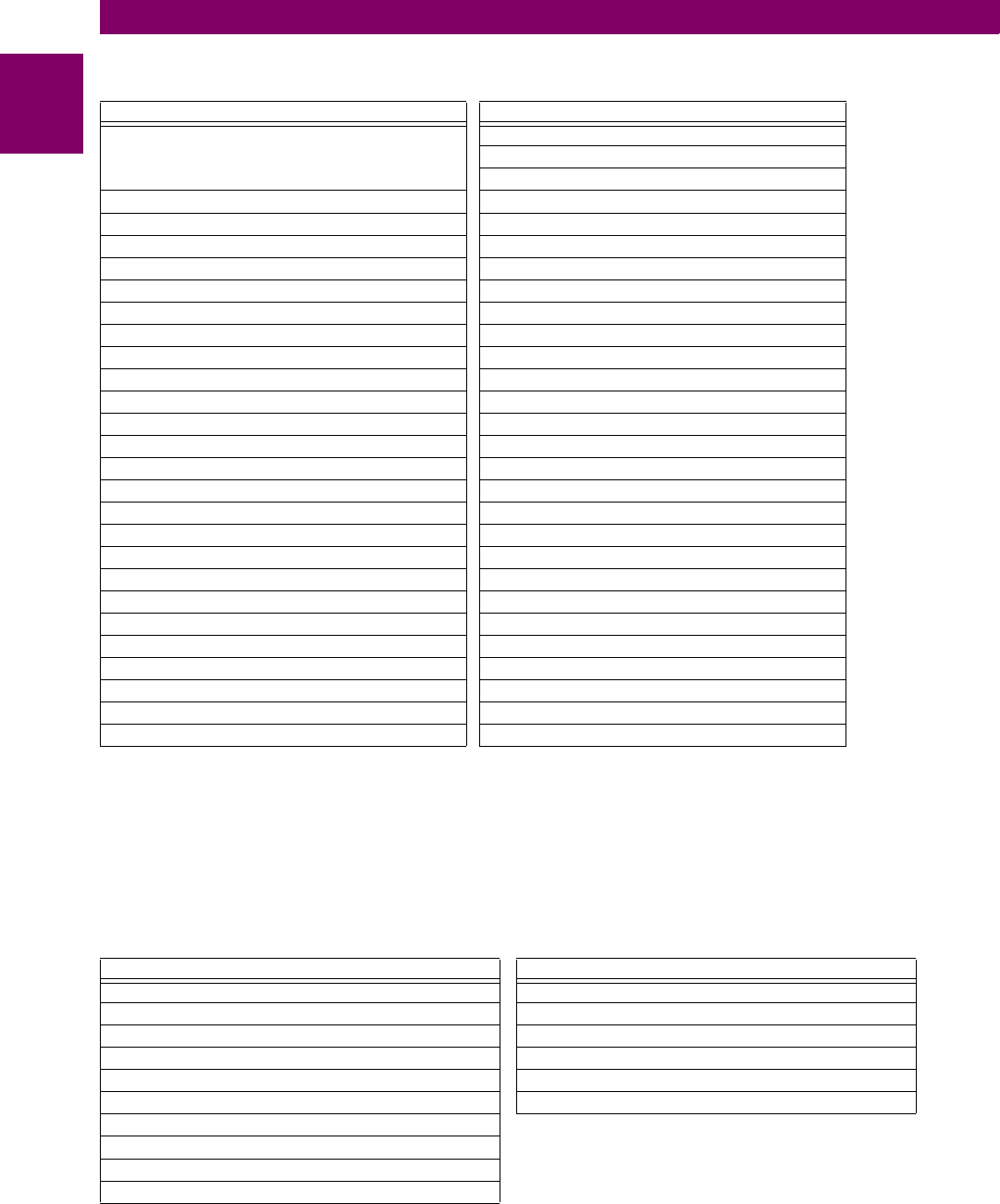

Table 1–1: TRIP AND ALARM PROTECTION FEATURES

TRIP PROTECTION ALARM PROTECTION

Seven (7) Assignable Digital Inputs: General Input,

Sequential Trip (low forward power or reverse power), Field-

Breaker discrepancy, and Tachometer

7 assignable digital inputs: general input and tachometer

Overload

Negative Sequence

Offline Overcurrent (protection during startup) Ground Overcurrent

Inadvertent Energization Ground Directional

Phase Overcurrent with Voltage Restraint Undervoltage

Negative-Sequence Overcurrent Overvoltage

Ground Overcurrent Volts Per Hertz

Percentage Phase Differential Underfrequency

Ground Directional Overfrequency

High-Set Phase Overcurrent Neutral Overvoltage (Fundamental)

Undervoltage Neutral Undervoltage (3rd Harmonic)

Overvoltage Reactive Power (kvar)

Volts Per Hertz Reverse Power

Voltage Phase Reversal Low Forward Power

Underfrequency (two step) RTD: Stator, Bearing, Ambient, Other

Overfrequency (two step) Short/Low RTD

Neutral Overvoltage (Fundamental) Open RTD

Neutral Undervoltage (3rd Harmonic) Thermal Overload

Loss of Excitation (2 impedance circles) Trip Counter

Distance Element (2 zones of protection) Breaker Failure

Reactive Power (kvar) for loss of field Trip Coil Monitor

Reverse Power for anti-motoring VT Fuse Failure

Low Forward Power Demand: Current, MW, Mvar, MVA

RTDs: Stator, Bearing, Ambient, Other Generator Running Hours

Thermal Overload Analog Inputs 1 to 4

Analog Inputs 1 to 4 Service (Self-Test Failure)

Electrical Lockout IRIG-B Failure

Table 1–2: METERING AND ADDITIONAL FEATURES

METERING ADDITIONAL FEATURES

Voltage (phasors) Drawout Case (for ease of maintenance and testing)

Current (phasors) and Amps Demand Breaker Failure

Real Power, MW Demand, MWh Trip Coil Supervision

Apparent Power and MVA Demand VT Fuse Failure

Reactive Power, Mvar Demand, Positive and Negative MVarh Simulation

Frequency Flash Memory for easy firmware upgrades

Power Factor

RTD

Speed in RPM with a Key Phasor Input

User-Programmable Analog Inputs