Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 47

Procedure for Counterbalance Pressure

Test

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

1. Park machine on a level surface with the cutting

decks lowered and off. Make sure hydraulic oil is at nor-

mal operating temperature, engine isoff and theparking

brake is applied.

2. Raise a nd support operator seat to gain access to

combination manifold.

3. Connect a 1000 PSI (70 bar) pressure gauge to test

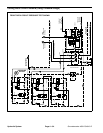

port G1 on combination manifold (Fig. 30).

NOTE: Thecuttingdecks needto bein the floatposition

when checking counterbalance pressure. Also, make

sure that all of the cutting deck castor wheels are on the

ground when testing or adjusting counterbalance pres-

sure.

IMPORTANT: While testing counterbalance pres-

sure,DO NOTraise any ofthe cuttingdecks.If decks

are raised, system pressure increase will damage

pressure gauge.

4. Start engine and increase engine speed to high idle

speed with no load on the hydraulic system. Do not en-

gage the cutting decks.

GAUGE READING TO BE approximately 325 PSI

(22.4 bar).

NOTE: The recommended counterbalance pressure

for your Groundsmaster is 325 PSI (22.4 bar).

5. Stop engine and record test results.

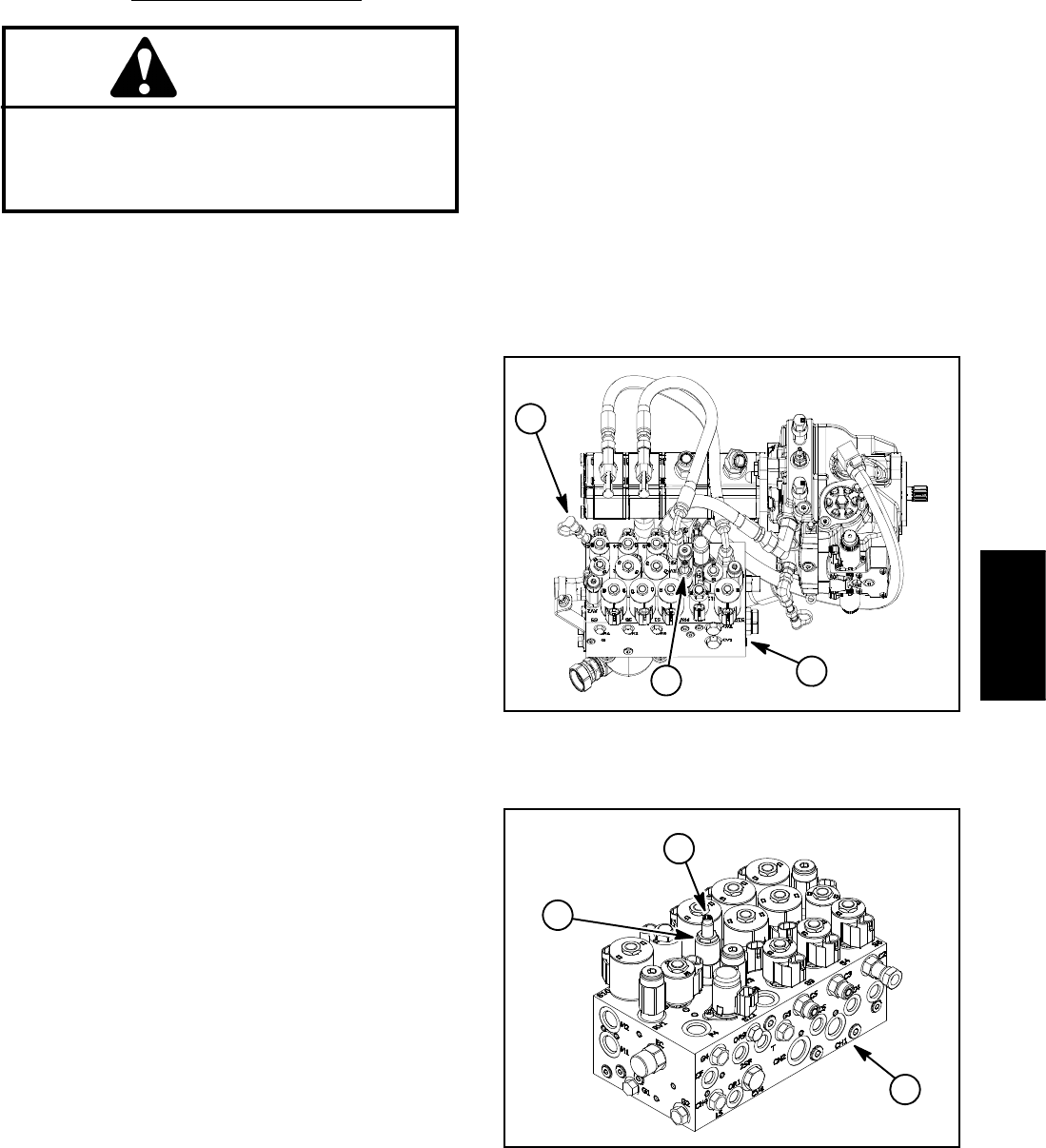

6. The pressure reducing valve on the combination

manifold is used to set the counterbalance pressure

(Fig. 31). If necessary, adjust pressure reducing valve:

NOTE: Becauseof valvedesign, the pressure reducing

valve can be adjusted with the engine running. Do not

remove the pressure reducing valve from the hydraulic

manifold for adjustment.

A. Locate pressure reducing valve on combination

manifold(Fig.31). Loosen locknuton pressureredu-

cing valve.

B. Start engine and increase engine speed to high

idle speed with no load on the hydraulic system. Do

not engage the cutting decks.

C. To increase pressure setting, turn the adjust-

ment screw on the valve in a clockwise direction. A

1/8turn onthe screwwill makea measurablechange

in counterbalance pressure.

D. To decrease pressure setting, turn the adjust-

ment screw onthe valve in a counterclockwisedirec-

tion. A 1/8 turn on the screw will make a measurable

change in counterbalance pressure.

E. Tighten lock nut to secure adjustment. Check

counterbalance pressure and readjust as needed.

7. When testing is completed, disconnect pressure

gauge from manifold test port. Secure dust cap to test

fitting. Lower operator seat.

1. Combination manifold

2. Test port G1

3. Pressure reducing valve

Figure 30

2

1

3

1. Combination manifold

2. Pressure reducing va lve

3. Adjustment screw

Figure 31

2

3

1

Hydraulic

System