Groundsmaster 4000--D/4010--DPage 6 -- 30Axles, Planetaries and Brakes

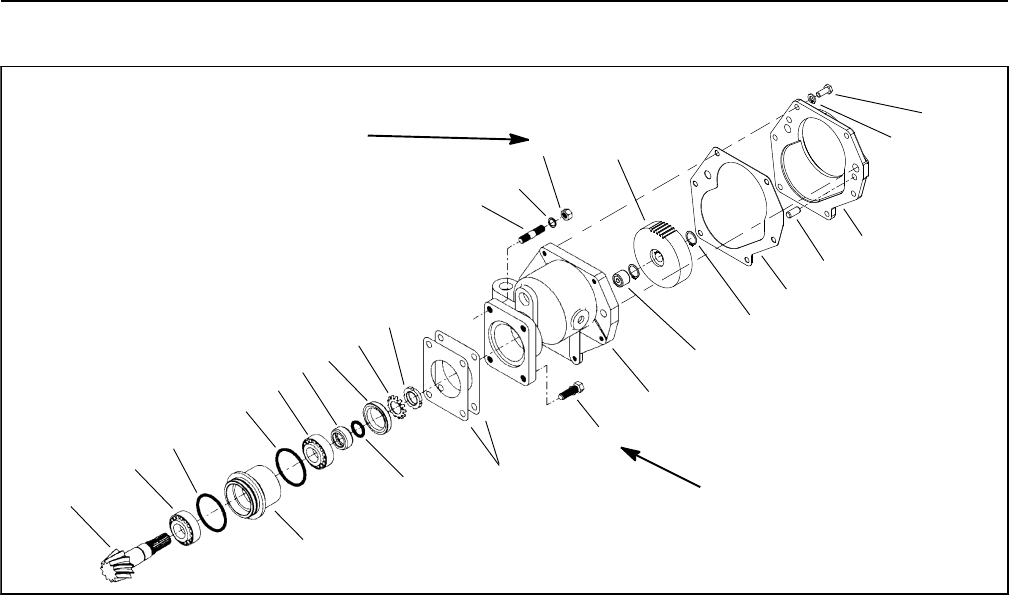

Input Shaft/Pinion Gear

Figure 35

1

1. Nut (2 used)

2. Lock washer (2 used)

3. Stud (2 used)

4. Lock nut

5. Stake washer

6. Oil seal

7. O-ring

8. Seal collar

9. Bearing

10. O-ring

11. Input shaft/pinion gear

12. Bearing case

13. Shim

14. Screw (2 used)

15. Gear case

16. Gasket

17. Cover plate

18. Dowel pin (2 used)

19. Lock washer (6 used)

20. Cap screw ( 6 used)

21. Retaining ring (2 used)

22. Driven gear (45 tooth)

23. Needle bearing

2

3

4

5

6

7

8

9

10

9

11

12

13

14

15

16

17

10

18

35 to 41 ft--lb

(47to56N--m)

35 to 41 ft--lb

(47to56N--m)

19

20

22

21

23

The following procedures assume the rear axle assem-

bly has been removed from the machine.

Removal (Fig. 35)

1. Remove the cover plate, gasket and gear case as -

sembly from theaxle assembly.Remove the gasket and

any remaining gasket material.

2. Remove the retaining rings, the driven gear and the

needle bearing from the input shaft/pinion gear.

3. Remove input shaft/pinion gear assembly from the

gear case. Remove the shims and bearing case O-

rings.

4. Release the stake washer and remove the lock nut.

Remove and discard the stake washer.

5. Drive the input shaft/pinion gear out from the outer

bearing cone and bearing case. Remove and discard

the oil seal and O-ring.

6. Inspect all gears, shafts, b earings, spacers and

cases for damage and wear. Replace components as

necessary.

NOTE: Replacement input shaft/pinion gear (item 11)

is only available in matched set with differential ring

gear.

Installation (Fig. 35)

NOTE: When installing bearing cones onto the input

shaft/pinion gear, press only on the inner race of the

bearing cone.

1. If the inner bearing cone was removed, press a new

bearingconea ll theway onto theinputshaft/piniongear.

2. Place the shaft and bearing assembly in the bearing

case and install t h e outer b earing cone.

NOTE: The bearings must be completely seated.

There should be no input shaft/pinion gear end play.

3. Coat a new oil seal with grease and install as shown

in Figure 36. The seal should be installed with thegarter

spring towards the hydraulic motor location.

4. Coat new O-ring with grease. Install O-ring in the oil

seal collar and install the collar.