Groundsmaster 4000--D/4010--D Page 5 -- 29 Electrical System

Electrical System Quick Checks

Battery Test (Open Circuit)

Use a multimeter to measure the voltage between the

battery terminals.

Set multimeter to the DC volts setting. The battery

should be at a temperature of 60

o

to 100

o

F(16

o

to

38

o

C). Theignition key should beoff andall accessories

turned off. Connect the positive (+) multimeter lead to

the positive battery post and the negative (--) multimeter

leadto thenegative battery post.The multimeterwilldis-

play battery voltage.

NOTE: This testprovides arelative condition of thebat-

tery. Load testing of the battery will provide additional

and more accurate information.

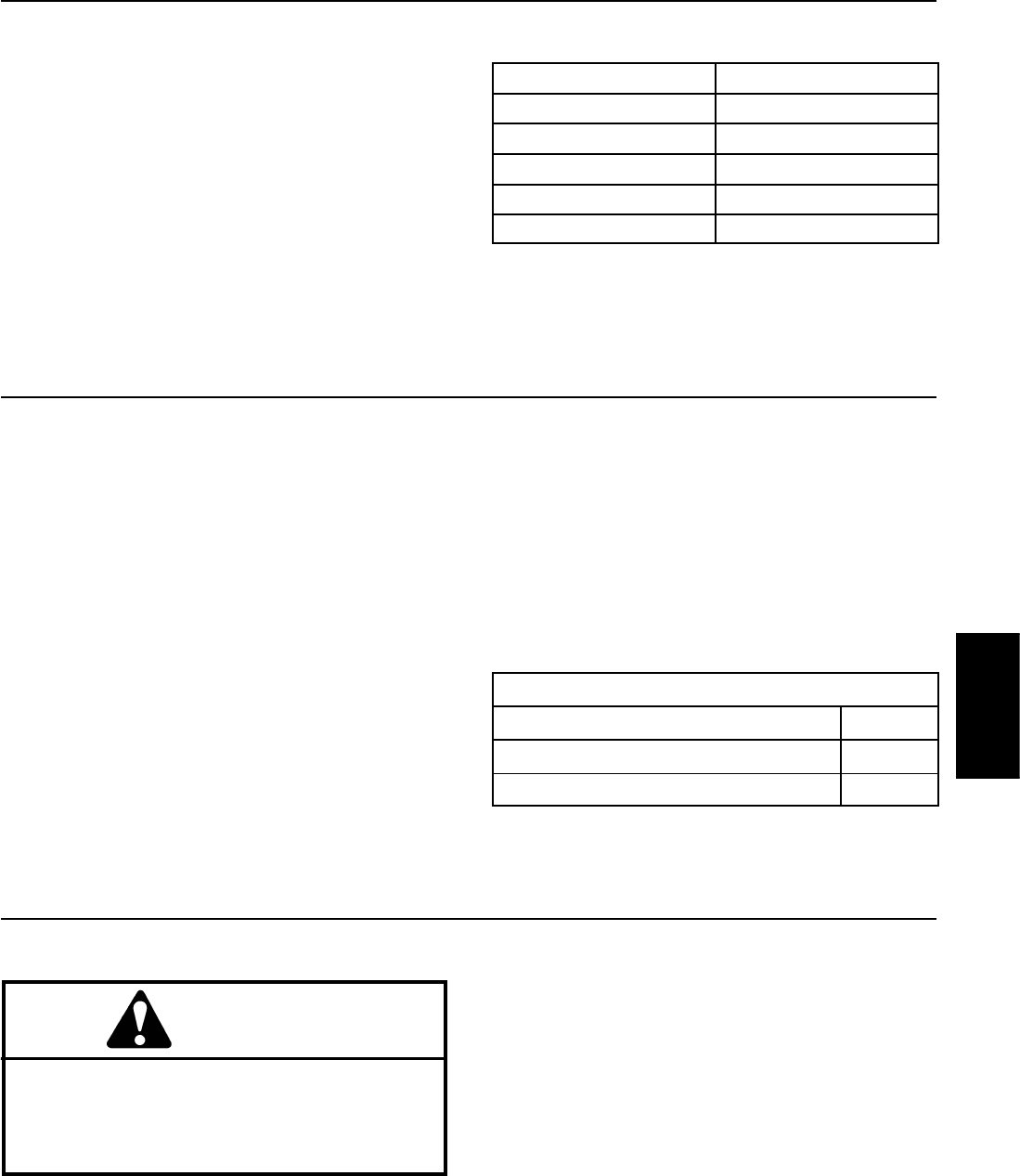

Voltage Measured

Battery Charge Level

12.68 V (or higher) Fully charged (100%)

12.45 V 75% charged

12.24 V 50% charged

12.06 V 25% charged

11.89 V 0% charged

Charging System Test

This is a simple test used to determine if a charging sys-

tem is functioning. I t will tell you if the charging system

has an output, but not its capacity.

NOTE: The InfoCenter display can be used to identify

battery voltage during machine operation.

Use a digital multimeter set to DC volts. Connect the

positive (+) multimeter lead to the positive battery post

and thenegative (--) multimeterlead to the negative bat-

tery post. Keep the test leads connected to the battery

posts and record the battery voltage.

NOTE: Upon starting the engine, the battery voltage

will drop and then should increase once the engine is

running.

NOTE: Depending upon the condition of the battery

charge and battery temperature, the battery voltage will

increase at different rates as the battery charges.

Start the engine and run at high idle. Allow the battery

to charge for at least three ( 3) minutes. Record the bat-

tery voltage.

After running the engine for at least three (3) minutes,

battery voltage should be at least 0.50 volt higher than

initial battery voltage.

An example of a charging system that is functioning:

At least 0.50 volt over initial battery voltage.

Initial Battery Voltage = 12.30 v

Battery Voltage after 3 Minute Charge = 12.95 v

Difference =+0.65v

Check Operation of Interlock Switches

CAUTION

Do not disconnect safety switches. They are for

the operator’s protection. Checkthe operationof

the interlockswitches daily forproper operation.

Replace any malfunctioning switches before o p-

erating the machine.

Interlock switch operation is described in the Traction

Unit Operator’s Manual. Your Groundsmaster is

equipped with t wo (2) Toro Electronic Controllers (TEC)

which monitor interlock switch operation. Testing of indi-

vidual interlock switches and relays is included in the

Component Testing section of this Chapter.

NOTE: Use the InfoCenter Display when troubleshoot-

ing an electrical problem on your Groundsmaster.

Electrical

System