Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 5

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston (traction) pump may occur.

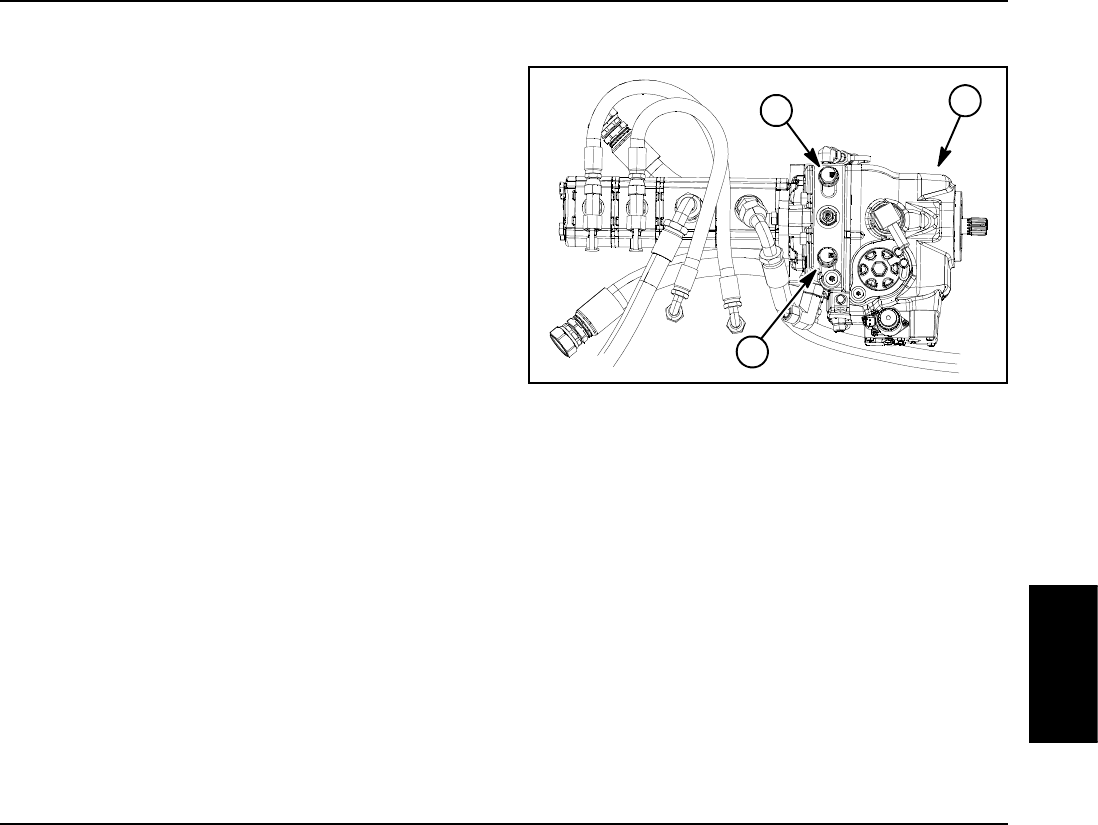

If it becomes necessary to tow (or push) the machine,

tow (or push) in a forward direction only and at a

speed below3 mph (5 kph).The piston (traction) pump

relief valves (both forward and reverse) need to be

loosened three (3) revolutions to allow the machine to

be moved (Fig.2). To preventleakage from reliefvalves,

do not loosen them more than three (3) revolutions.

Refer toyour Operator’s Manual foradditionaltowing in-

structions.

IMPORTANT: Do not loosen relief valves when en-

gine is running.

Before returning machine to service, tighten both of the

relief valves untilseated. Then, torquerelief valvesto 52

ft--lb (70 N--m).

IMPORTANT: If the machine must to be pushed or

towed inreverse,the check valvein the rear traction

manifold must also be bypassed. To bypass this

check valve, connect a hydraulic hose assembly to

the reverse traction pressure test port, located on

the piston (traction) pump, and on the port located

in--between ports M8 and P2 on the rear traction

manifold which is located behind the front tire. Use

Toro part numbers 95--8843 (hydraulic hose),

95--0985 (quantity 2) (coupler fitting) and 340--77

(quantity 2) (hydraulic fitting).

Figure 2

1. Piston pump

2. Relief valve (forward)

3. Relief valve (reverse)

1

2

3

Traction Circuit Component Failure

The traction circuit on Groundsmaster 4000--D and

4010--D machines is a closed loop system that includes

the piston (traction) pump, two (2) front wheel motors

and the rear axle motor. If a component in the traction

circuit should fail, debris and contamination from the

failed component will circulate throughout the traction

circuit. This contamination can damage other compo-

nents in the circuit so it must be removed to prevent

additional component failure.

The recommended method of removing traction circuit

contamination would be to temporarily install the Toro

high flow hydraulic filter (see Special Tools in this chap-

ter) into the circuit. This filter should be used when con-

necting hydraulic test gauges in order to test traction

circuitcomponents orafter replacinga failedtraction cir-

cuit component (e.g. traction (piston) pump or wheel

motor). The filter will ensure that contaminates are re-

movedfrom theclosed loop and thus, do not causeaddi-

tional component damage.

Once the Toro high flow hydraulic filter kit has been

placed in the circuit, raise and support the machine with

all wheels off the ground. Then, operate the traction cir-

cuit to allow oil flow throughout the circuit. The filter will

remove contamination from the traction circuit during

operation. Because the Toro high flow filter is bi--direc-

tional, the traction circuitcan beoperated in both thefor-

ward and reverse direction. The filter should be

removed from the machine after contamination has

been removed from the traction circuit. See Filtering

Closed--LoopTraction Circuitin theService andRepairs

section of this chapter for additional information on us-

ing the Toro high flow hydraulic filter.

ThealternativetousingtheTorohighflowhydraulicfilter

kit after a traction circuit component failure would be to

disassemble, drain and thoroughly clean all compo-

nents, hydraulic tubes and hydraulic hoses in the trac-

tion circuit. If any debris remains in the traction circuit

and themachine isoperated, thedebris can cause addi-

tional circuit component failure.

Hydraulic

System