Groundsmaster 4000--D/4010--DPage 7 -- 12Chassis

Rear Arm Installation (Fig. 9)

1. Position rear arm assembly to cutting deck and

frame.

2. Slidepivot shaftthroughrear armclevis andhub.Se-

cure pivot shaft with lock washer (item 24) and lock nut

(item 25).

3. Connect damper link to cutting deck with clevis pin

(item 5) and hair pin (item 6).

4. Position spacers on both sides of rod end of rear arm

assembly. Secure rod end of rear arm assembly to deck

mount with cap screw (item 3) and lock nut (item 4).

5. Lubricate rear arm grease fittings.

6. Align cutting deck to traction unit as follows:

A. Make sure the machine is on a level, hard sur-

face.

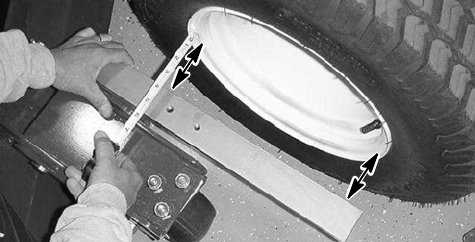

B. Place a square or straight edge against the deck

weldment that contains the castor fork assembly

(Fig. 12). Do not use the castor fork assembly itself.

C. Measure from the inset bead of the rim (not the

outeredge ofthe rim)to the straight edgeat twoloca-

tions as indicated in Figure 12. Rim and paint irregu-

laritiesmake therim outer edge anunreliablepointof

measure. These two measurements should be the

same within a tolerance of 1/8” (3 mm).

D. Rotate spring shaft (item 12) in rear a rm assem-

bly until correct dimension is attained. Shaft should

rotate freely inside the assembly. All adjustments

must be made with the rod end of the rear arm bolted

to the deck.

E. Raise and lower the deck and recheck dimen-

sions for correct alignment.

F. When deck is properly aligned to traction unit,

tighten rod end jam nut (item 9).

NOTE: Due to differences in turf conditions and the

counterbalance setting of traction unit, it is advised that

turf be cut and appearance checked b efore formal cut-

ting is started. Refert o Operator’s Manual for correcting

cutting deck mismatch procedures.

Figure 12