Groundsmaster 4000--D/4010--D Page 7 -- 19 Chassis

IMPORTANT: A properly installed and calibrated

traction pedal position sensor is critical to accurate

traction system response and for reliable sensor

life. Use care when removing, installing and cali-

brating t he traction pedal position sensor.

Disassembly (Fig. 17)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply park ing brake and remove

key from the ignition switch.

2. Remove front steering tower cover (see Steering

Tower in this section).

3. Disconnect machine wire harness connector from

position sensor (item 28) on traction pedal.

4. If the tractionpedalis tobe removed fromthetraction

pedalshaft,use amarkeror paint penon pedal andshaft

to identify location of pedal for assembly purposes.

5. Disassemble tractionpedal asneeded usingFigures

17 and 18 as guides. When removing roll pin (item 10 in

Fig. 17), make sure to support shaft to prevent compo-

nent damage.

Assembly (Fig. 17)

1. Assemble traction pedal using Figures 17 and 18 as

guides noting the following items:

A. Apply grease to both the OD and ID of the spring

retainer (item 35 in Fig. 17) before installation. Take

caretonotget greaseonthreads ofspring shaft(item

32 in Fig. 17) or lock nut (item 37 in Fig. 1 7).

B. If lock nut (item 37 in Fig. 17) was removed, tight-

en nut until washer (item 36 in Fig. 17) does not ro-

tate.

C. If traction pedal shaft (item 9 in Fig. 17) was re-

moved, apply grease to the shaft areas that will be

inside the bearings after assembly.

D. Use a press to install roll pin (item 10 in Fig. 17).

DO NOT damage flange mount bearing ( item 17 in

Fig. 17) or cover plate (item 18 in Fig. 17) when in-

stalling roll pin. Also, take care to not distort roll pin

during assembly.

E. Make sure that roll pin (item 10 in Fig. 17) is fully

inside the butterfly groove of the shim plate (item 20

in Fig. 17). The roll pin should not contact the shim

plate throughout the operating range.

F. To install the traction pedal position sensor (item

28 in Fig. 17), press and holdthe traction pedal in the

reverse direction slightly. Align the slot on the end of

the pedal shaft with the slot in the position sensor.

Slideposition sensoronto screwsand releasepedal.

Hold position sensor in position while installing cap-

tureplate (item29 inFig. 17) andlock nuts(item25 in

Fig. 17).

G. Torque screws (item 31 in Fig. 17) from 13 to 17

in--lb (1.5 to 1.9 N--m).

H. Leave the hex nut (item 7 in Fig. 17) loose so that

the position sensor can be calibrated.

2. After traction pedal assembly, make sure that there

is no binding in pedal movement and also that pedal re-

turns to the centered position when released. Correct

any sticking or binding before machine operation.

3. Plug machine wire harness connector into traction

pedal position sensor (item 28 in Fig. 17).

4. Afterassembly ofthe tractionpedal, adjustand calib-

rate the traction pedal and position sensor using the In-

foCenter display (see Traction Pedal Adjustment and

Traction Pedal Calibration in the Adjustments section of

Chapter 5 -- Electrical System).

5. Make sure thathex nut (item 7 inFig. 17) istightened

after position sensor adjustment.

6. Install front steeringtower cover(see Steering Tower

in this section).

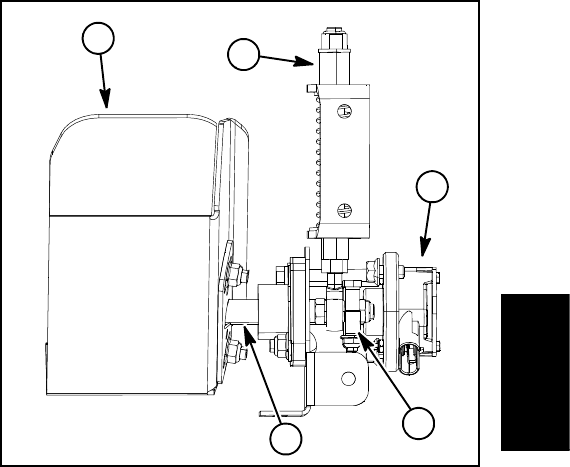

1. Traction pedal

2. Pedal position sensor

3. Traction pedal shaft

4. Clamp block (2 used)

5. Spring shaft assembly

Figure 18

1

2

4

3

5

Chassis