Groundsmaster 4000--D/4010--DPage 6 -- 8Axles, Planetaries and Brakes

2. Apply gasket sealant to sealing surfaces of new gas-

ket (item 18). Apply gasket to brake assembly.

3. Install brake assembly onto machine, aligning

splined brake shaft with input shaft on planetary wheel

drive. Make sure that brake pull rod is orientated toward

rear of machine.

4. Secure brake assembly to planetary assembly with

four (4) flange head screws (item 16). Tighten screws in

acrossingpatterntoatorquefrom75 to 85 ft--lb (101

to 115 N--m).

5. Securehex onend of brakecableto pullrod onbrake

assembly. Brake cable end should be completely

threaded onto pull rod before tightening jam nut.

6. Install new O--ring on hydraulic wheel motor. Install

wheel motor and torque cap screws from 75 to 85 ft--lb

(101 to 115 N--m).

7. Install wheel assembly.

NOTE: While front wheel is off the ground, check plan-

etary wheel drive assembly for endplay (see Planetary

Wheel Drive Assembly Endplay in the Adjustments sec-

tion of this chapter).

WARNING

Failure to maintain proper wheel lug nut torque

could result in failure or loss of wheel and may

result in personal i njury.

8. Lower machine to ground. Torque lug nuts from 85

to100ft--lb(115to135N--m).

9. Make sure drain plugs are installed in brake and

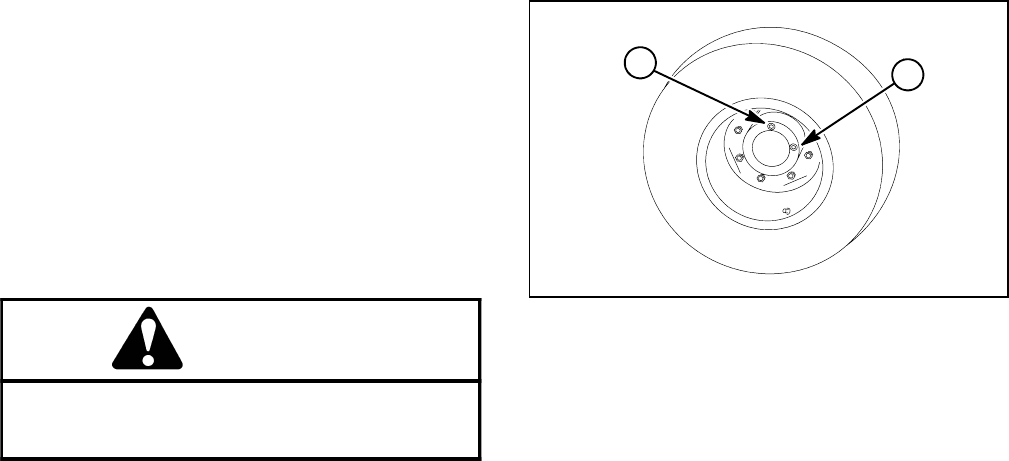

planetary drive assemblies (Fig. 2).

10.Fill planetary wheel drive/brake assembly with SAE

85W--140 gear lube (Fig. 5). Capacity is approximately

22 fl. oz. (0.65 liters) per wheel.

11.Check and adjust brake cables for proper brake op-

eration. If necessary, adjust hex on end of brake cable

so that pull rod jam nut is positioned from 0.340” to

0.400” (8.7 to 10.1 mm) from brake casting surface

when brakes are disengaged (Fig. 4). Brakes should be

adjusted so that both brake pedals have approximately

1” (25mm) of freeplay and have equal brake tension.

1. Check plug 2. Fill plug

Figure 5

1

2