25

CONTROL BOARD POTENTIOMETER ADJUSTMENTS (Continued)

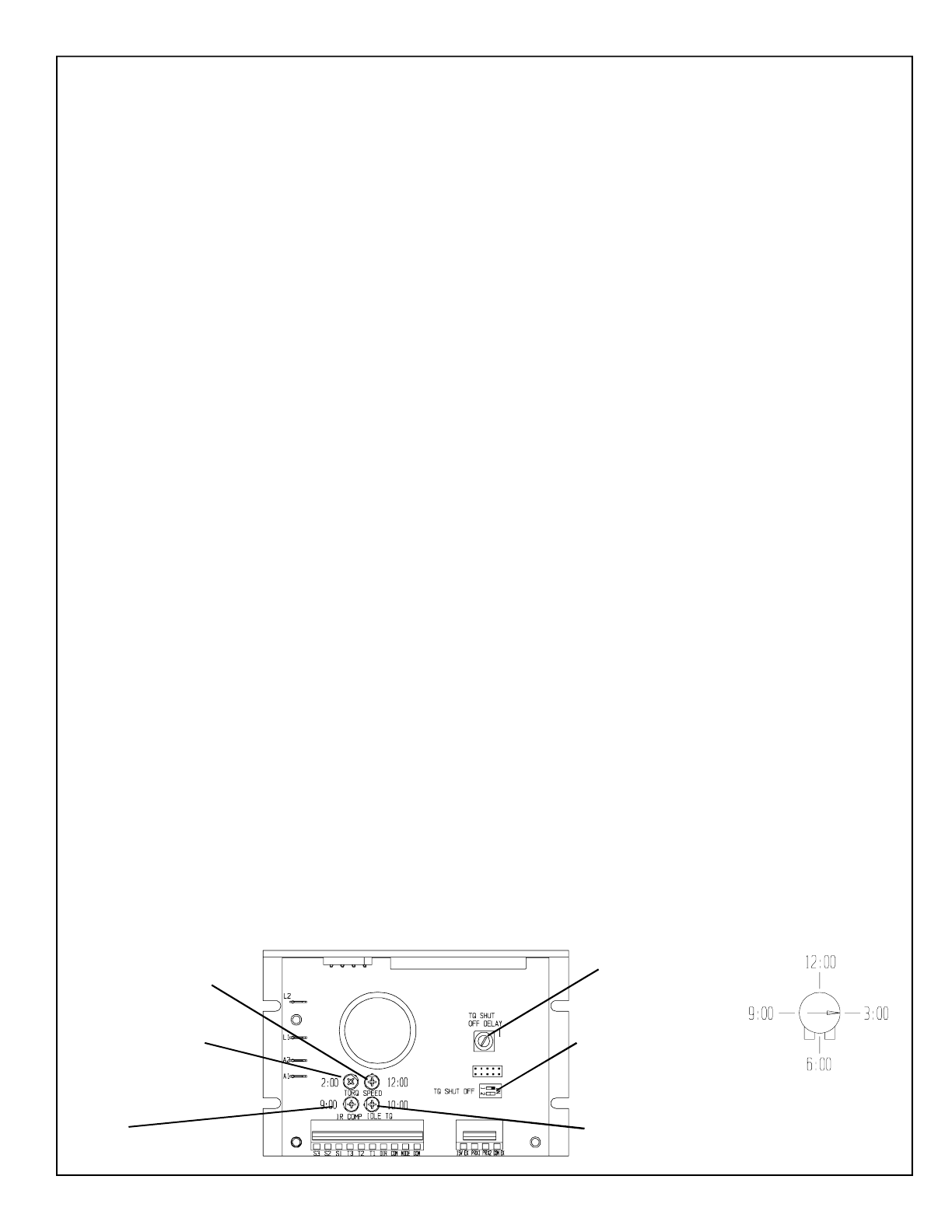

SPIN DRIVE CONTROL BOARD (SDC)

The Spin Drive Control Board has four potentiometers, two switches and one dial as shown on FIG. 24. These

potentiometers,swtiches and dial have been set at the factory to the positions shown on FIG. 24.

In the Relief Grinding Mode--

The Torque Shut Off mode selector allows you to turn on or off the Torque Shut Off feature. When switch 1 is set to ON, the

board will decrease the spin motor torque once the shut time is achieved after leaving the right proximity sensor. The amount

of time it takes before the torque is decreased is set with the Torque Shut Off Delay dial. The spin motor toque will be

increased to the higher value once the right proximity switch is activated again. If the Torque Shut Off selector is in the OFF

position the torque will remain constant during relief grinding. This should be set to OFF.

Torque Shut Off Delay dail is used to set the duration of time before the torque is decreased after leaving the right proximity

sensor during relief grinding. If the dial is turned clockwise (higher number) the higher torque value will stay on for a longer

period of time.

The Relief Speed (RSP) and the Relief Torque Pot (RTP) interact with each other. The (RSP) is located on the spin board as a

remote speed preset at 12:00 (20 Volts DC). See FIG. 24. The (RTP) is located on the control panel and is for relief torque

adjustment.

Relief Speed Pot (SPEED) when rotated clockwise will increase spin drive speed (the speed at which the reel indexes to the

next blade). This speed should never be above the 3:00 setting.

Relief Torque Pot (TORQ) is used to vary the reel to finger holding torque for relief grinding. The

recommended starting point is 30 in/lbs of torque setting. Never adjust the (RTP) potentiometer dial past the red line marking.

Setting the reel to finger torque to high could cause the spin motor system to not operate smoothly.

Relief Idle Torque Pot (ITP) is used to vary the reel to finger holding torque once the shut time is achieved after leaving the right

proximity sensor if the Torque Shut Off Selector is set to on.

In the Spin Grinding Mode--

The Spin Torque Potentiometer (STP) and the Spin Speed Pot (SSP) interact with each other. The (STP) is located on the spin

board as remote torque preset at 2:00 for torque setting. See FIG. 24. The (SSP) is located on the control panel and is for spin

speed adjustment.

Spin Torque Pot (STP) controls maximum torque allowable in the spin grinding cycle only. This should never be adjusted past

the 3:00 position. If the reel does not turn check that the reel is free turning by hand spinning with the power off and the spin

drive disconnected.

The Spin speed Pot (SSP) controls reel spin speed, adjust as required. This controls the spin drive speed for spinning the reel.

IR COMP Pot--

The IR Compensation is factory set at 9:00.

Regulation of the spin or relief grind spin motor may be improved by a slight adjustment of the IR COMP pot clockwise from its

factory-set position. Overcompensation causes the motor to oscillate or to increase speed when fully loaded. If you reach such

a point, turn the IR COMP pot counterclockwise until symptoms just disappear.

FIG. 24

SPIN TORQUE POT

(TORQ) 2:00

IR COMP

POT

9:00

IDLE TORQUE

POT (ITP)

10:00

RELIEF SPEED

POT (SPEED) 12:00

SWITCH 1

SET TO OFF

DELAY SET

TO 1

Potentiometer Clock

Orientation