13

DO NOT GREASE GRINDING SHAFT

BEARINGS FOR THE FIRST 2 YEARS. THEY

ARE GREASED AT THE FACTORY. GREASING

MAY CAUSE THE BEARINGS TO OVERHEAT

AND FAIL PREMATURELY.

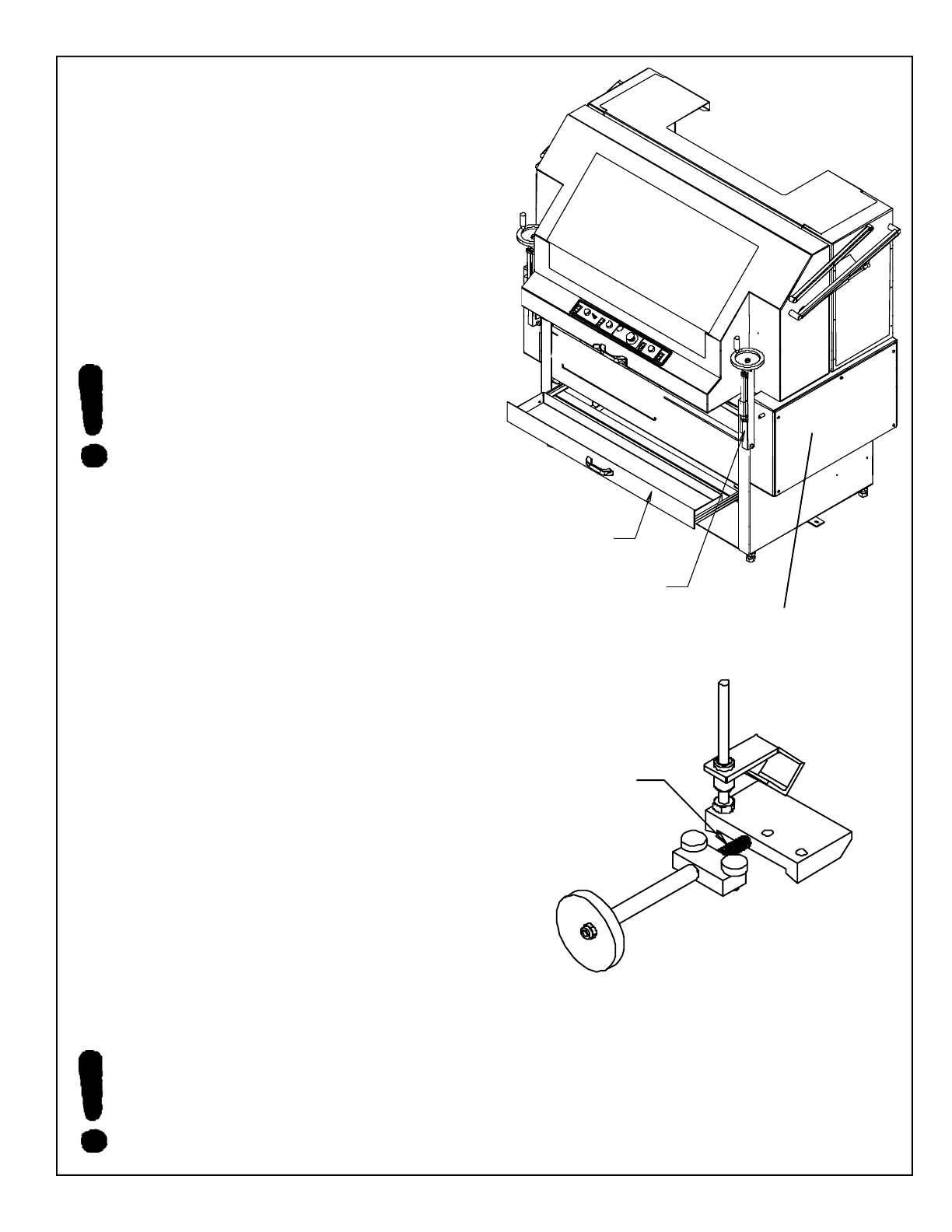

1. Clean the dust tray located at the lower front

of the machine monthly using a vacuum or

by removing it. Pull the tray out until the back

of the tray is even with the front of the frame

and vacuum it out. To remove continue to

pull straight out until the tray is free.

2. Inspect the Poly-V belt on the grinding motor

for cracking and make any

necessary adjustments every three months.

3. Wipe off and lubricate with never-seize, the

horizontal adjustment shafts located on the

tooling every six months.

4. Wipe off and lubricate with never-seize, the

vertical adjustment shafts every six months.

Run the arms up and down to coat the

working areas of the shaft.

5. Inspect the traverse cog belt for

cracking and defects every three months.

Remove any grit or dust that may affect the

function of the belt. Adjust tension if

necessary per procedures called out in the

adjustment section. See FIG 9.

6. Clean and lubricate the grinding shaft and

traverse shafts every 2 to 4 weeks. Follow

the proceedure on the next page.

7. Lubricate grinding shaft bearings with one

shot of grease once every 2 years. See

FIG 9.

DAILY MAINTENANCE IS SPECIFIED ON PAGE 6,

AND IS TO BE PERFORMED BY THE OPERATOR.

LISTED BELOW ARE PERIODIC MAINTENANCE

ITEMS TO BE PERFORMED BY YOUR

COMPANY'S MAINTENANCE DEPARTMENT:

USE CAUTION WHEN PULLING THE

TRAY OUT AS THERE IS NO

MECHANICAL STOP. WHEN REMOVING

TRAY PULL STRAIGHT OUT AND

SUPPORT THE TRAY TO PREVENT

DUMPING.

PERIODIC MAINTENANCE

FIG. 8

FIG. 7

DUST TRAY

VERTICAL ADJUSTMENT

SHAFTS LOCATED INSIDE

HOUSING - ACCESS THRU

SIDE PANELS

HORIZONTAL

ADJUSTMENT

SHAFT

POLY-V BELT LOCATED

BEHIND PANEL