Greensmaster eFlex 1800/2100 Page 4 -- 37 Electrical System

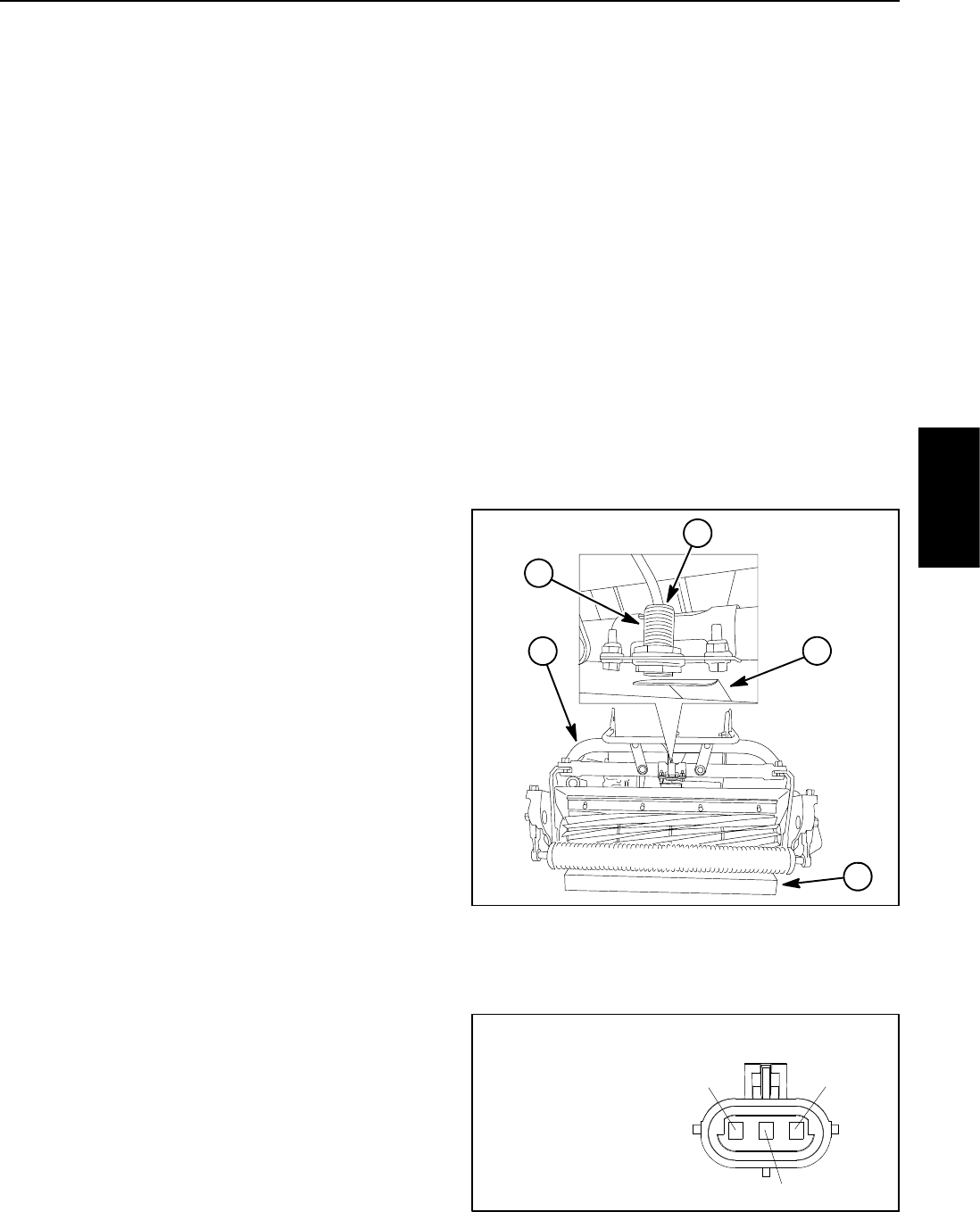

EZ Turn Sensor

The EZ turn sensor is a normally open proximity sensor

that mounts to a bracket mounted to the cutting unit roll

frame (Fig. 47). The sensing plate for the sensor is a tar-

get plate attached to the top of the cutting unit assembly.

The TECcontroller monitors theoperation of theEZ turn

sensor.

When the traction unit is supported on the traction drum

with the cutting unit supported by both front and rearroll-

ers on level ground, the target end of the EZ turn sensor

is positioned away from the target plate on the cutting

unit so the sensor is open. The EZ turn sensor is moved

toward the cutting unit target plate when the cutting unit

is raised for turning, causing the sensor to close.

NOTE: The EZ turn sensor LED should be illuminated

whenever the machine is operational (key switch in the

RUN position) and the cutting unit is raised.

NOTE: TheEZturnfunctionisonlyactivewhenthema-

chine is being operated with the cutting unit engaged.

Also, the EZ turn switch and EZ turn sensor are in series

so both switch and sensorhave to be ON for the EZ Turn

function to be ON. If either the switch or the sensor is

OFF, the EZ Turn function will be OFF.

NOTE: Information on EZ turn sensor adjustment is in-

cluded in the eFlex Operator’s Manual.

Sensor Testing

1. Park machine on level surface and place traction le-

ver in the NEUTRAL position.

2. Turn key switch to the START position to wake up the

machine and then turn key switch to the RUN position.

3. Check LED on cable end of EZ turn sensor:

A. The sensor LED should not beilluminated when

the cutting unit is being supported by both front and

rear rollers on level ground.

B. The sensor LED should be illuminated when the

cutting unit is raised (handle pushed down).

4. If the EZ turn sensor LED did not function correctly:

A. Make sure that EZ turn sensor is properly ad-

justed (see Operator’s Manual). If necessary, adjust

sensor and return to step 4 above.

B. Make sure key switchis OFF andthen disconnect

the EZ turn sensor connector from the machine wire

harness.

C. TurnkeyswitchtotheSTARTpositiontowakeup

the machine and then turn key switch to the RUN

position.

D. Connect multimeter common (--) test probe to

harness connector terminal C (black wire) and sec-

ond test probe to harness connector terminal A (pink

wire) (Fig. 48). Verify with the multimeter that har-

ness connector has 12 VDC circuit voltage present.

E. If sensor connector has circuit voltage present

and sensor LED did not function, replace EZ turn

sensor. Adjust sensor after installation (refer to Op-

erator’s Manual).

5. After EZ turn sensor testing is complete, plug sensor

connector into machine wire harness.

6. Connect the battery pack (see Lithium Battery Pack

Connection in the General Information section of this

chapter).

1. EZ turn sensor

2. Target plate

3. Cutting unit roll frame

4. Sensor LED location

5. 1.5” block under roller

Figure 47

1

2

3

4

5

Figure 48

PINK wire at A

ORANGE wire at B

BLACK wire at C

A

B

C

WIRE HARNESS CONNECTOR FOR SENSOR

Electrical

System