Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 33

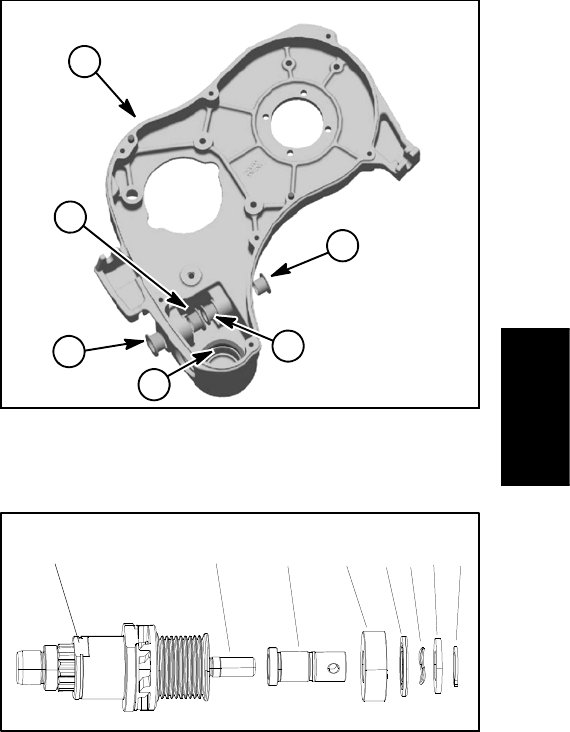

6. Inspect flange bushings and reel brake ring for wear

or damage (Fig. 40). Replace bushings and brake ring

if necessary.

Reel Clutch Shaft Disassembly (Fig. 39)

NOTE: The following procedure covers complete dis-

assembly of reel clutch shaft assembly. Depending on

service needs of machine, it may not be necessary to

perform every step of this procedure.

IMPORTANT: When removing flex coupler (item 2)

from clutch shaft, do not mar outer surface of cou -

pler (e.g. g rasping with pliers or mounting in vise)

as coupler may be damaged and fail prematurely.

1. Support flex coupler (item 2) to prevent it from being

damaged during spring pin removal. Push spring pin

from flex coupler and bearing collar (item 23). Slide cou-

pler with hex shaft (item 3) from collar. Discard removed

spring pin.

2. Press ball bearing (item 28) from end of reel clutch

shaft. Discard removed bearing.

3. Carefully remove retaining ring (item 13) that se-

cures reel brake disc (item 14) to reel drive hub (item

18). Take care to not damage brake disc friction material

when removing retaining ring.

4. Remove reel brake disc (item 14) from reel drive hub

noting orientation of disc for assembly purposes. Fric-

tion material side of disc needs to be positioned toward

the reel brake ring (item 11) which is pressed into the

transmission housing.

5. Slide reel clutch hub (item 17) and reel clutch fork

(item 16) assembly from reel drive hub (item 18). Note

correct orientationof indicator mark on fork for assembly

purposes. If necessary, remove pivot pins (item 15) and

separate fork from hub.

6. Use modified socket (see Special Tools in this chap-

ter) to remove bearing collar assembly from clutch shaf t

(Fig. 41).

IMPORTANT: To prevent damage, avoid using ex-

cessive clamping pressure on the reel clutch shaft

assembly.

A. Use flats on reel drive hub to carefully secure reel

clutch shaft assembly in a vise. Use a vise with soft

jaws to prevent damage to clutch shaft assembly

components.

B. Slide modified socket over bearing collar. Align

modified socket so that 5/32” pin can be inserted

through socket and hole in bearing collar.

C. Use modified socket and socket wrench to re-

move bearing collar assembly from clutch shaft.

1. Transmission housing

2. Flange bushing

3. Flange bushing

4. Reel brake ring

Figure 40

1

2

4

3

3

2

Figure 41

1. Retaining ring

2. Flat washer

3. Wave spring

4. Flocked bearing seal

5. Ball bearing

6. Bearing collar

7. Reel clutch shaft

8. Hub flat location

21345678

7. Remove retaining ring (item 27), flat washer (item

26), wave spring (item 25) and flocked bearing shield

(item 24) from bearing c ollar. Note orientation of flocked

shield for assembly purposes.

8. Press bearing (item 12) from bearing collar. Discard

removed bearing.

9. Slide reel clutch pulley assembly and reel drive hub

from clutch shaft.

10.If necessary, remove ball bearings and spacer from

pulley. Discard removed bearings.

Reel Clutch Shaft Assembly ( Fig. 39)

1. If ball bearings were removed from reel clutch pulley,

press new inner bearing fully to bottom of bore in pulley.

Install spacer into pulley and then press new outer bear-

ing into pulley until it contacts spacer.

2. If bearing was removed from bearing collar, press

new bearing fully onto collar.

Traction and Reel

Drive System