Greensmaster eFlex 1800/2100Page 4 -- 46Electrical System

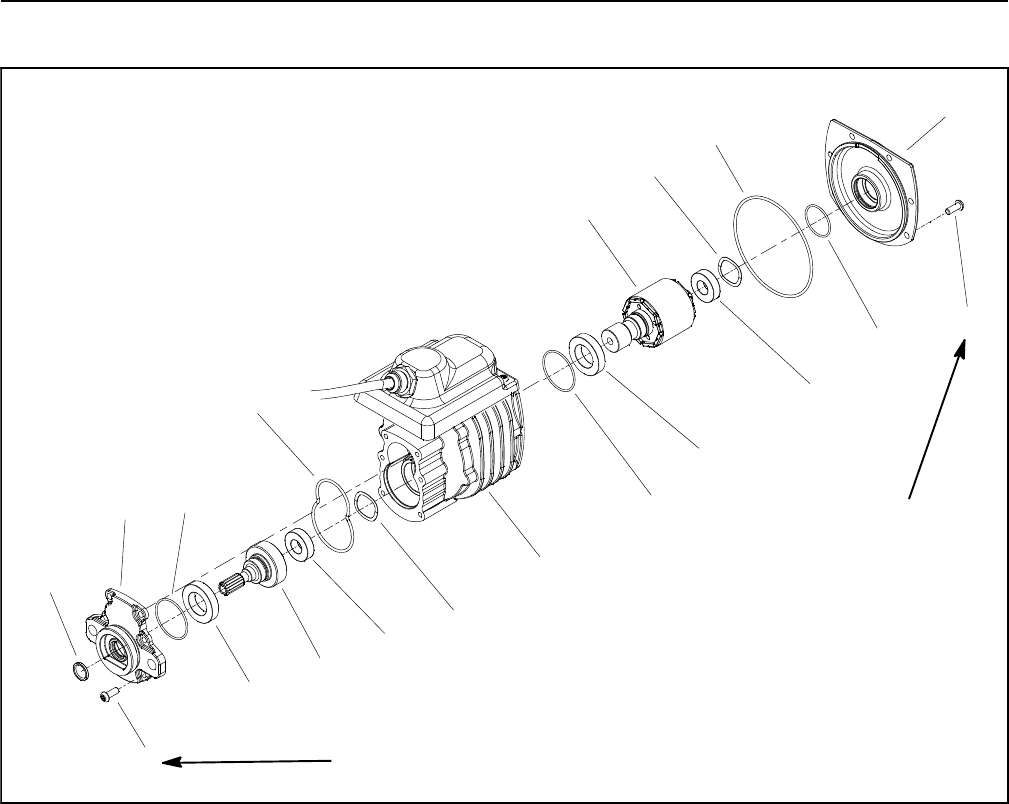

Electric Motor Service

1. Torx head screw (12 used)

2. Motor cover

3. O--ring

4. Wave washer (2 used)

5. Bearing (2 used)

6. Rotor

7. Bearing (2 used)

8. O--ring (2 used)

9. Housing/controller/cable assembly

10. O--ring

11. Output gear

12. Gearbox cover

13. Shaft seal

14. O--ring

Figure 58

5

7

7

5

6

11

8

1

4

3

10

8

9

12

14

13

2

4

1

35 to 45 in--lb

(4 to 5 N--m)

35 to 45 in--lb

(4 to 5 N--m)

NOTE: If motor housing, controller or cable damage oc-

curs, electric motor replacement is necessary. These

components are not available separately.

NOTE: If problems with electric m otor exist, an adviso-

ry or fault m ay be identified on the InfoCenter display.

Refer to InfoCenter Display in this chapter for informa-

tion on advisories and faults.

Disassembly (Fig. 58)

1. Remove six (6) torx head screws that secure gear-

box cover (item 12) to front of motor housing.

2. Carefully slide gearbox cover from front of motor.

3. Remove and discard O--rings (items 8 and 10) from

gearbox cover.

4. Slide output gear assembly (items 5, 11 and 7) from

motor housing. Remove wave washer (item 4).

5. Remove six (6) torx head screws that secure motor

cover (item 2) to rear of motor housing.

IMPORTANT: The rotor magnets are very powerful

and can cause the rotorto shift position very rapidly

during removal. Be cautious during rotorremovalto

prevent component damage or personal injury.

6. Use electric m otor rotor tool set (see Special Tools in

this chapter) to carefully remove rotor assembly (items

5, 6 and 7) and motor cover (item 2) from motor housing.

7. Remove motor cover and wave washer (item 4) from

rotor assembly. Remove and discard O--rings (items 14

and 3) from cover.