Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 41

4. Remove RH drum drive cover and drive belt from

machine ( see Drum Drive Belt in this section).

5. Remove electric motor from machine (see Electric

Motor in the Service and Repairs section of Chapter 4

-- Electrical System).

6. Remove battery pack from machine (see Battery

Pack in the Service and Repairs section of Chapter 4 --

Electrical System).

7. Remove four (4) washer head screws (item 8) that

secure extension housing (item 17) to RH drum hous-

ing.

8. Support transmission to prevent it from falling.

9. Remove fasteners that secure transmission to ma-

chine frame.

A. Flange head screw (item 2) that secures front of

transmission to frame.

B. Cap screw (item 13), hardened washer (item 14)

and flange head screw (item 16) that secure rear of

transmission to frame.

10.Carefully move transmission assembly toward left

side of machine until extension housing is clear of RH

drum housing. Lift transmission from machine.

11.To disassemble transmission, refer to Transmission

Drive Belt, Transmission Idler System, Transmission

Reel Drive System, Transmission Drive System and

Transmission Drum Drive System in this section.

Transmission Installation

1. Make sure that all internal transmission components

are correctly installed before transmission is installed to

machine frame.

2. Carefully install transmission assembly toward right

side of machine so that extension housing is inserted

into RH drum housing.

3. Align transmission mounting holes with frame and

RH drum housing. Install and finger tighten fasteners to

secure transmission to machine.

A. Four (4) washer head screws (item 8) that secure

extension housing (item 17) to RH drum housing.

B. Cap screw (item 13), hardened washer (item 14)

and flange head screw (item 16) that secure rear of

transmission to frame. Make sure that washer (item

14) is below frame tube.

C. Flange head screw (item 2) that secures front of

transmission to frame.

4. Once all fasteners have been installed, fully tighten

fasteners in the following order:

A. Four (4) washer head screws (item 8). First,

torque all screws from 15 to 40 in--lb (1.7 to 4.5

N--m). Then, using an alternating crossing pattern,

torque screws from85 to 95 in--lb (9.6 to10.7 N--m).

B. Cap screw (item 13) and flange head nut (item

16) that secure rear of tr ansmission to frame.

C. Flange head screw (item 2) that secures front of

transmission to frame.

5. Install battery pack to machine (see Battery Pack in

the Service and Repairs sectionofChapter 4 -- Electrical

System).

6. Install electric motor to transmission (see Electric

Motor in the Service and Repairs section of Chapter 4

-- Electrical System).

7. Install drum drive belt and RH drum drive cover to

machine (see Drum Drive Belt in this section).

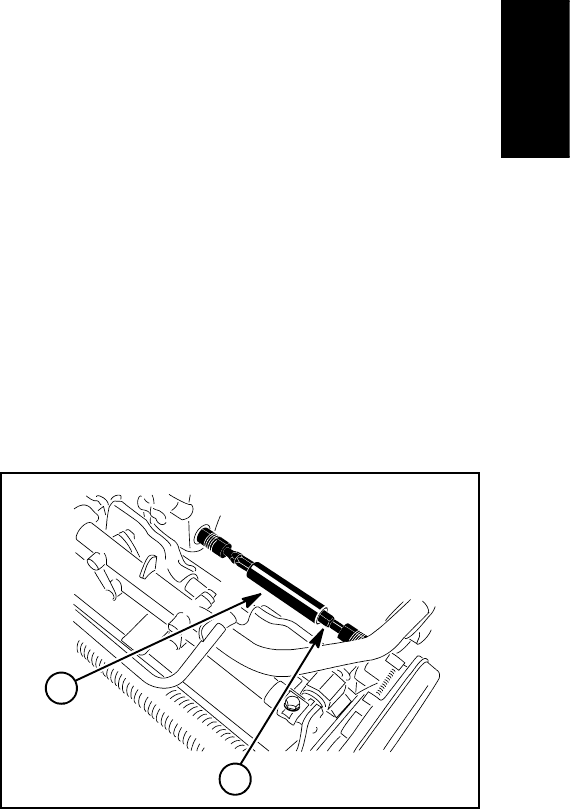

8. Slide the telescoping coupler onto the cutting unit

hex shaft (Fig. 48).

9. Connect reel clutch cable to transmission (see Reel

Clutch Cable Replacement in the Service and Repairs

section of Chapter 6 -- Chassis and Controls).

10.Connect the batterypack (see Battery PackConnec-

tion in the General Information section of this chapter).

1. Telescoping coupler 2. Cutting unit hex shaft

Figure 48

1

2

Traction and Reel

Drive System