TROUBLESHOOTING & REPAIR M300EU

Addendum to M300E/EM Manual P/N 04288

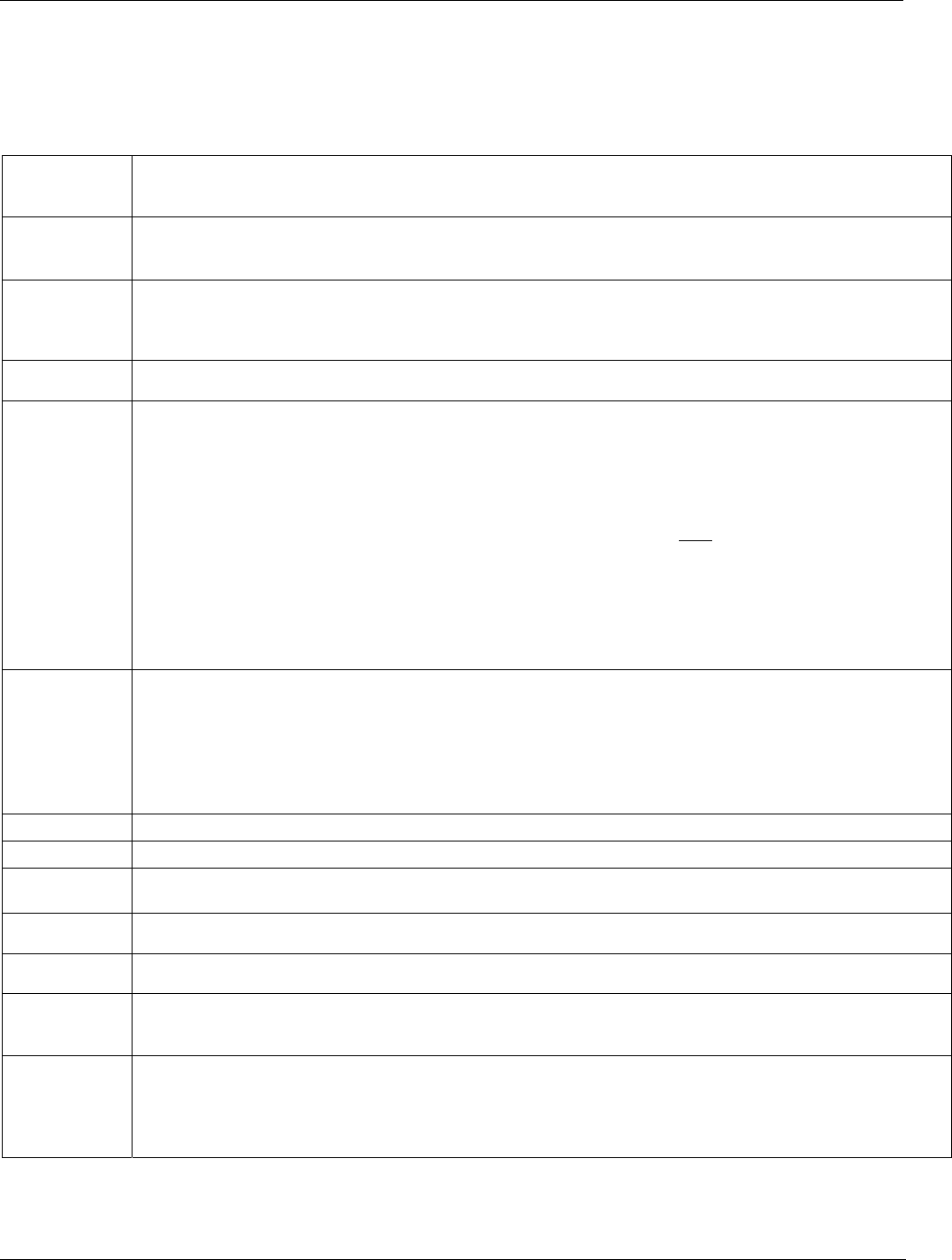

11.2.1. FAULT DIAGNOSIS WITH TEST FUNCTIONS

The following table supersedes Table 11.2 of the M300E/EM Operators Manual (P/N 04288).

Table 11-2: Test Functions - Indicated Failures

TEST

FUNCTIONS

(As Displayed)

INDICATED FAILURE(S)

TIME

Time of day clock is too fast or slow

To adjust See Section 6.6of the M300E/EM Operators Manual (P/N 04288).

Battery in clock chip on CPU board may be dead.

RANGE

Incorrectly configured measurement range(s) could cause response problems with a Data logger or chart

recorder attached to one of the analog output.

If the Range selected is too small, the recording device will over range.

If the Range is too big, the device will show minimal or no apparent change in readings.

STABIL

Indicates noise level of instrument or CO concentration of sample gas (See Section 11.4.2 of the M300E/EM

Operators Manual for causes).

CO MEAS

&

CO REF

If the value displayed is too high the IR Source has become brighter. Adjust the variable gain potentiometer on

the sync/demod board (See Section 11.6.3 of the M300E/EM Operators Manual)

If the value displayed is too low or constantly changing and the CO REF is OK:

o Failed multiplexer on the mother board

o Failed sync/demod board

o Loose connector or wiring on sync/demod board

If the value displayed is too low or constantly changing and the CO REF is

BAD:

o GFC wheel stopped or rotation is too slow

o Failed sync/demod board IR source

o Failed IR source

o Failed relay board

o Failed

I

2

C buss

o Failed IR photo-detector

MR RATIO

When the analyzer is sampling zero air and the ratio is too low:

o The reference cell of the GFC wheel is contaminated or leaking.

o The alignment between the GFC wheel and the segment sensor, the M/R sensor or both is incorrect.

o Failed sync/demod board

When the analyzer is sampling zero air and the ratio is too high:

o Zero air is contaminated

o Failed IR photo-detector

PRES

See Table 11-1 for SAMPLE PRES WARN

SAMPLE FL

Check for gas flow problems. see Section 11.1.6 of the M300E/EM Operators Manual)

SAMPLE

TEMP

SAMPLE TEMP should be close to BENCH TEMP. Temperatures outside of the specified range or oscillating

temperatures are cause for concern

BENCH TEMP

Bench temp control improves instrument noise, stability and drift. Temperatures outside of the specified range

or oscillating temperatures are cause for concern. See Table 11-1 for BENCH TEMP WARNING

WHEEL TEMP

Wheel temp control improves instrument noise, stability and drift. Outside of set point or oscillating

temperatures are causes for concern. See Table 11-1 for WHEEL TEMP WARNING

BOX TEMP

If the box temperature is out of range:

o Check the motherboard stabilization fan (see Figure 3-1).

o See Table 11-1 for BOX TEMP WARNING.

OVEN TEMP

If the oven is temperature is out of range, check both of the oven heater fans in the power supply module.

Areas to the side and rear of instrument should allow adequate ventilation.

o Check the both of the oven fans (see Figure 3-1).

o Check both of the oven heaters.

See Table 11-1 for OVEN TEMP WARNING.

(table continued)

62 05514 Rev A1