M300EU THEORY OF OPERATION

(Addendum to M300EU Manual - P/N 04145)

10.2.2. THE A-REF VALVE ASSEMBLY

The auto-reference valve assembly is located next to the optical bench, at the rear of the analyzer between the

Nafion

®

dryer and the outer wall of the instrument (see Figure 3-1). The following table describes the state of

each valve during the analyzer’s various operational modes (see Figure 10-1).

Table 10-1: Auto-Reference Valve Operating States

Mode Valve State VALVE PORT CONNECTIONS

SAMPLE

(Normal State)

Gas stream from Nafion

®

Dryer &

SAMPLE inlet

3 Æ 2

A-REF DWELL

Gas stream from CO scrubber

1 Æ 2

A-REF MEASUREMENT

Gas stream from CO scrubber

1 Æ 2

SAMPLE DWELL

Gas stream from Nafion

®

Dryer &

SAMPLE inlet

3 Æ 2

10.2.3. THE NAFION

®

DRYER.

Normal room air contains a certain amount of water vapor. While H

2

O is a very low-level interferent for IR

absorption (in the same range as CO) it can cause enough interference to affect the high-resolution

measurements of the M300EU.

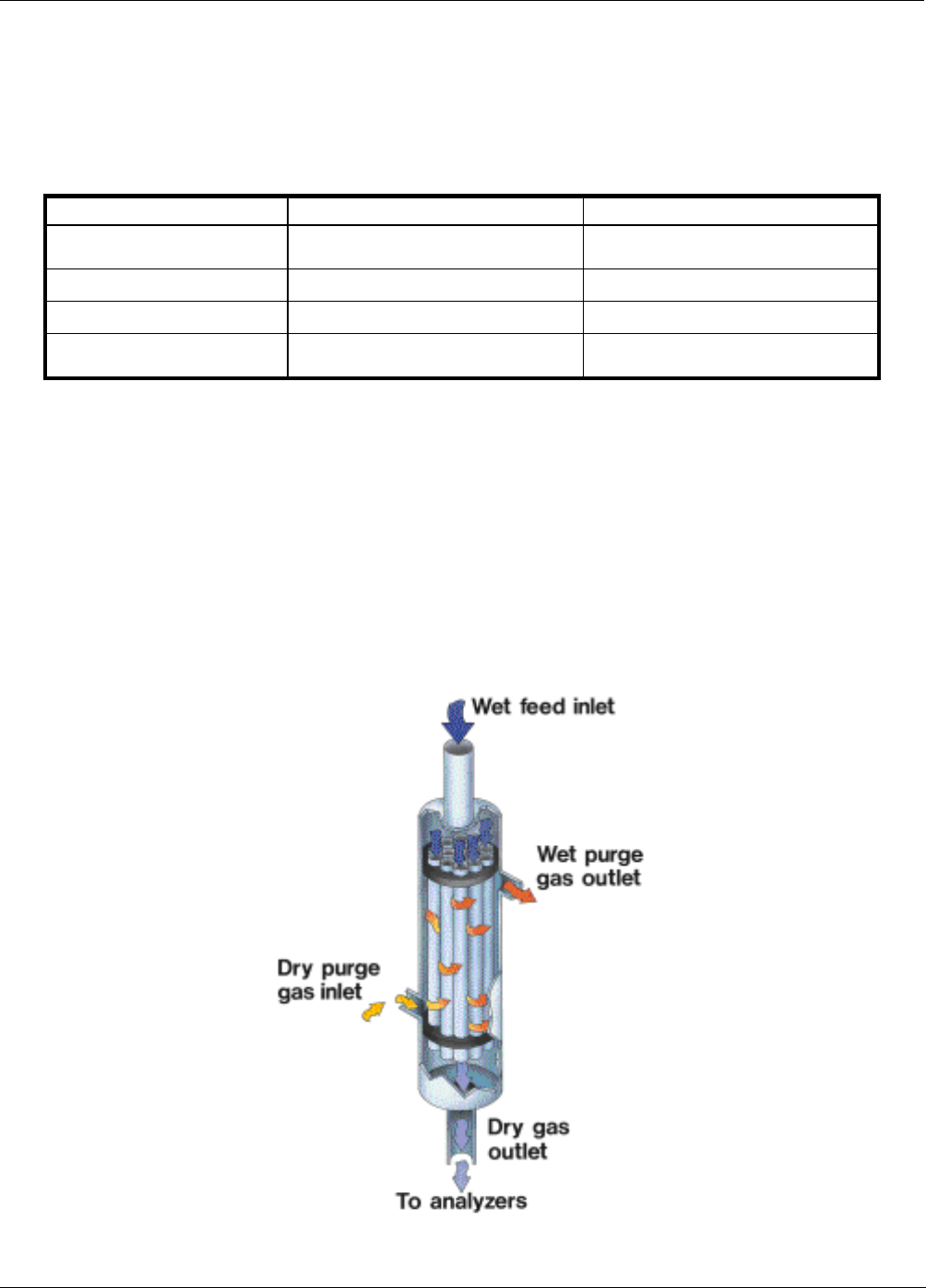

To account for this the M300EU has a special dryer added to the gas stream. The dryer consists of a bundle of

parallel tubes of Nafion

®

, a co-polymer similar to Teflon

®

that absorbs water very well but not other chemicals.

The multiple tube design of this dryer creates a large reactive surface without causing a restriction in the higher

gas flow rate required by the M300EU that a long single tube style dryer would.

Figure 10-3: Semi-Permeable Membrane Drying Process

05514 Rev A1 51