45

Section 5: Maintenance & Lubrication

12/15/15

RCF3696, RCFM3696, RCF3610, & RCFM3610 Rotary Cutters 326-600M

Table of Contents

Slip-Clutch Protected Drivelines

Cutter drive components are protected from shock loads

by a friction slip-clutch. The clutch must be capable of

slippage during operation to protect the gearbox,

driveline and other drive train parts.

Clutch Run-In

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity to remove

any oxidation that may have accumulated on friction

surfaces. To prevent driveline and gear box damage,

repeat “run-in” instructions at beginning of each season

and when moisture and/or condensation seizes inner

friction plates.

!

WARNING

Always disengage PTO, engage parking brake, shut off

tractor, remove ignition key, and wait for all moving parts to

come to a complete stop before dismounting tractor to make

adjustments.

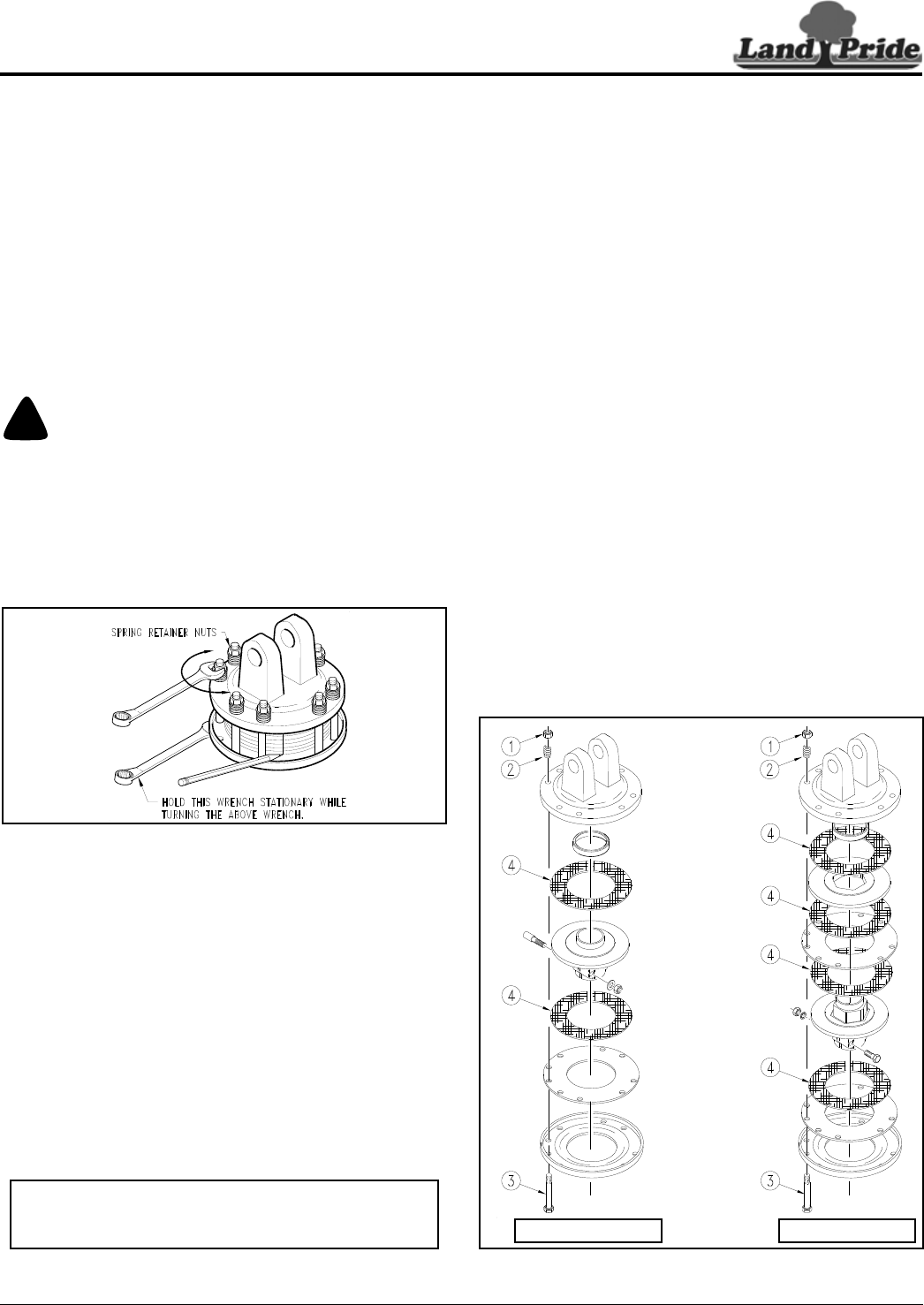

Refer to Figure 5-3:

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction discs.

Clutch

Figure 5-3

2. Carefully loosen each of the 8 spring retainer nuts on

the clutch housing a total of EXACTLY 2 revolutions.

It will be necessary to hold the hex end of the retainer

bolt in order to count the exact number of revolutions.

3. Start tractor and engage driveline for 2-3 seconds to

permit slippage of the clutch surfaces. Disengage the

PTO, then re-engage a second time for 2-3 seconds.

Disengage the PTO, shut off tractor and remove key.

Wait for all components to stop before dismounting

from tractor.

4. Inspect clutch and ensure that scribed markings

made on the clutch plates have changed position.

Slippage has not occurred if any two marks on the

friction disc and plate are still aligned.

5. Tighten each spring retainer nut on the clutch

housing exactly 2 revolutions to restore clutch to

13693

IMPORTANT: If clutch run-in procedure indicated

that one or more friction disks did not slip, the clutch

must be disassembled to separate the friction discs.

original setting pressure. See Figure 5-5 on page 46

and tables below Figure 5-5 for exact spring length.

6. The clutch should be checked during the first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to check for slippage.

Clutch Disassembly

Refer to Figure 5-4:

Disassembly of the clutch is simply a matter of removing

the spring retainer nuts (#1), springs (#2) and bolts (#3)

from the assembly. Each friction disc (#4) must then be

separated from the metal surface adjacent to it.

Clutch Inspection

Inspect all parts for excessive wear and condition. Clean

all parts that do not require replacement.The original

friction disc thickness is 1/8" (3.2 mm) and should be

replaced if thickness falls below 3/64" (1.1 mm). If

clutches have been slipped to the point of “smoking”, the

friction discs may be damaged and should be replaced.

Heat build-up may also affect yoke joints.

Clutch Assembly

Refer to Figure 5-4:

Install new friction discs if needed and reassemble all

components in proper order. Reassemble each friction

disc (#4) next to the metal plate it was separated from.

Install bolts (#3) through the end plates and intermediate

plates as shown. Place springs (#2) over the bolts and

secure with nuts (#1).

Slip Clutch Assembly

Figure 5-4

4-Plate Assembly2-Plate Assembly

35010