12

Section 1: Assembly & Set-Up

RCF3696, RCFM3696, RCF3610, & RCFM3610 Rotary Cutters 326-600M

12/15/15

Table of Contents

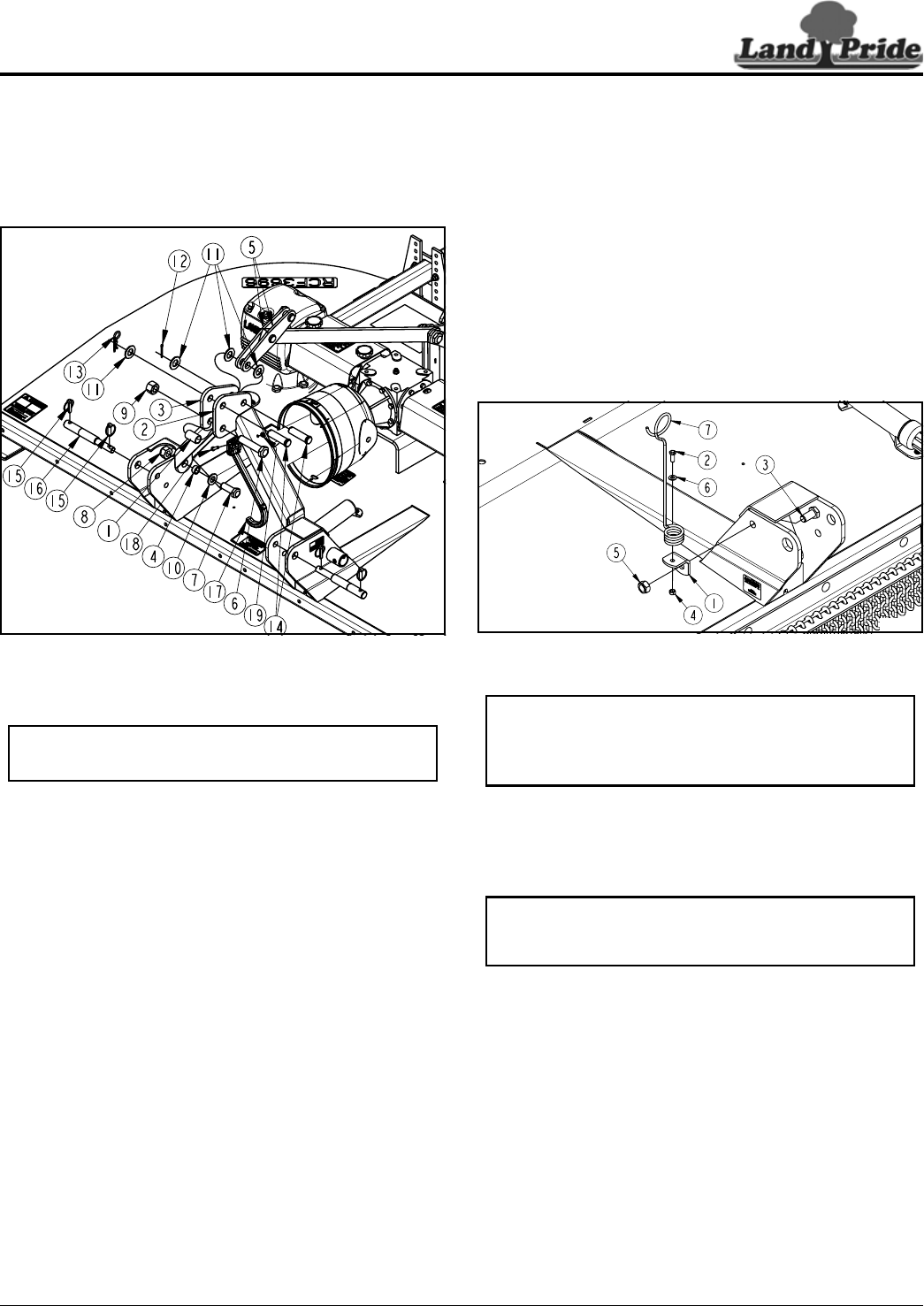

Spring Hose Loop Assembly

Refer to Figure 1-5:

3-Point mounted cutters with hydraulic cylinder option are

shipped with a spring hose loop. Skip to “Driveline

Installation” on page 19 if hydraulics are not included.

1. Attach mounting bracket (#1) with 3/4"-10 x 1 1/2"

GR5 cap screw (#3) and lock nut (#5) to the outside

of the right-hand clevis as shown. Tighten lock nut to

the correct torque.

2. Attach spring hose loop (#7) to mounting bracket (#1)

with 3/8"-16 x 1" GR5 cap screw (#2), flat washer

(#6), and lock nut (#4). Tighten lock nut to the correct

torque.

RCF(M)3610 3-Point Spring Hose Loop Mount

Figure 1-5

RCF(M)3696 Tailwheel Assembly

These instructions apply only to 96" models with rear

axle hydraulic lift. If hydraulics are not included with your

cutter, skip to “Driveline Installation” on page 14.

Refer to Figure 1-6:

1. There are several cylinder mounting lugs (#5) that

can be installed on axle (#1). Refer to NOTES IN

BOLD in Figure 1-6 to make sure your cutter is

equipped with the correct mounting lug and that the

notch in the lug is located on the axle properly. See

your nearest Land Pride dealer if it is not correct.

2. Install washers (#3) as follows:

RCF(M)3696 With 15" Tailwheels

• Install two 2 1/4" O.D. machine washers (#3) onto

each tailwheel spindle (#6).

RCF(M)3696 With 21" Tailwheels

• Install one special 4" O.D. harden washer (#3) onto

each tailwheel spindle (#6).

35005

NOTE: The RCF(M)3696 & RCFM3696 3-point

cutters are shipped with tailwheels factory mounted.

The RCF3610 & RCFM3610 are shipped with

tailwheels not assembled to the unit.

NOTE: If preferred, rear guards may be assembled

before the tailwheels. See “Assembly of Optional

Equipment” on page 28 for rear guard instructions.

3-Point Assembly & Set-Up

The following pages are Assembly & Set-Up Instructions

for 3-point cutters. Not all instructions will apply to your

cutter. See “Semi-Mount Assembly & Set-Up” on page

17 and “Pull-Type Assembly & Set-Up” on page 22.

3-Point Hitch Assembly (RCF(M)3696 Shown)

Figure 1-4

Hitch Assembly

Refer to Figure 1-4:

1. Attach Right-hand A-Frame (#3) to hitch plate as

shown with 7/8"-9 x 2 1/2" GR5 cap screw (#7), flat

washer (#10), bushing (#4), and nylock nut (#8).

2. Repeat step 1 for the left-hand A-Frame (#2).

3. Attach short braces (#5) to A-Frames (#2 & #3) with

1" x 3 3/16" clevis pin (#14), three flat washers (#11),

and cotter pin (#12) as shown. Bend one or more legs

of the cotter pin to keep it from falling out.

4. Secure 1 1/4" OD. bushing (#1) between the two

A-Frame hitch plates (#2 & #3) with 1"-8 x 4 1/2" cap

screw (#6) and nylon lock nut (#9).

5. Install remaining clevis pin (#14), flat washer (#11)

and hairpin cotter (#13) to the A-Frame hitch

assembly (#2 & #3) as shown.

6. Attach driveline hook (#17) to A-frame (#2) using

5/16"-18 x 1 1/4" bolt (#18) and lock nut (#19).

7. Tighten all hardware to the correct torque.

8. Remove shipping bolt and nuts in hitch pin (#16) and

insert linchpins (#15).

33942a

NOTE: Do not tighten hardware until assembly is

complete. See “Torque Values Chart” on page 56.