21

Section 1: Assembly & Set-Up

12/15/15

RCF3696, RCFM3696, RCF3610, & RCFM3610 Rotary Cutters 326-600M

Table of Contents

Check Driveline Length & Clearance

Check Driveline Collapsible Length

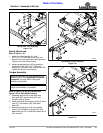

Refer to Figure 1-14 & Figure 1-17:

1. Make sure driveline is properly installed and level

before checking driveline collapsible length. Refer

to “Driveline Installation” instructions on page 14 or

“Driveline Installation” on page 19

2. With driveline level, measure 1" (“B” dimension)

back from universal joint shield to end of outer

driveline shield as shown in Figure 1-16.

3. If measurement is 1" or more, skip to “Check

Driveline Clearance” on this page. If measurement

is less than 1", continue with “Shorten Driveline”.

Shorten Driveline

Refer to Figure 1-16:

Be sure to first check driveline collapsible length above. If

required, shorten driveline as follows:

1. Unhook driveline from tractor PTO shaft and pull

outer and inner drivelines apart.

2. Reattach outer driveline to tractor PTO shaft. Pull on

inner and outer drivelines to be sure universal joints

are properly secured.

3. Hold inner and outer drivelines parallel to each other:

a. Measure 1" (“B” dimension) back from outer

driveline universal joint shield and make a mark at

this location on the inner driveline shield.

b. Measure 1" (“B” dimension) back from the inner

driveline universal joint shield and make a mark at

this location on the outer driveline shield.

4. Remove driveline from tractor and gearbox shafts.

5. Measure from end of inner shield to scribed mark

(“X” dimension). Cut off inner shield at the mark. Cut

same amount off the inner shaft (“X1” dimension).

6. Measure from end of outer shield to scribed mark

(“Y” dimension). Cut off outer shield at the mark. Cut

same amount off the outer shaft (“Y1” dimension).

7. Remove all burrs and cuttings.

8. Apply multi-purpose grease to the inside of the outer

shaft and reassemble driveline.

9. Reattach driveline to cutter and tractor. For detailed

instructions, see steps 11 to 13 under “3-Point Hook-

Up to RCF(M)3696 Cutters” on page 15 or steps 11

and 12 under “Semi-Mount Hook-Up” on page 20.

10. Continue with “Check Driveline Clearance”.

IMPORTANT: A driveline that is too long can bottom

out causing structural damage to tractor and cutter.

Always check driveline collapsed length during initial

setup, when connecting to a different tractor, and

when alternating between using a quick hitch and a

standard 3-point hitch. More than one driveline may

be required to fit all applications.

Driveline Shortening

Figure 1-16

Check Driveline Clearance

1. Make certain driveline yokes are properly attached.

2. Start tractor and raise cutter up just enough to

remove support blocks. Remove support blocks.

3. Slowly and carefully raise cutter to ensure drawbar,

tires, and other equipment on the tractor do not

contact cutter frame. Move or remove drawbar if it

interferes with cutter.

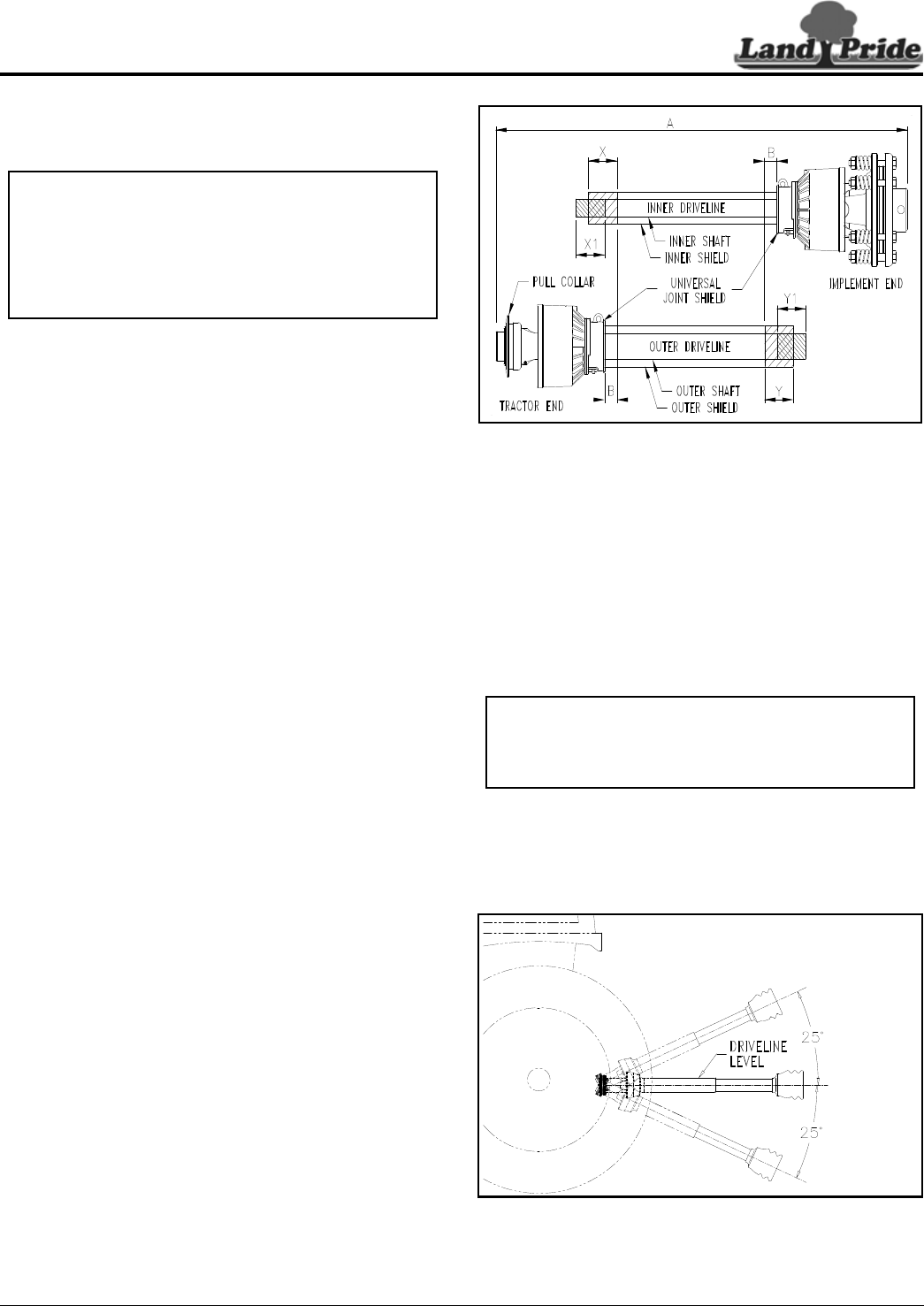

Refer to Figure 1-17:

4. Raise and lower implement to find maximum

extended driveline length. Check to make certain

driveline does not exceed 25

o

up or down.

5. If needed, set tractor 3-point lift height to keep

driveline from exceeding 25

o

up.

Maximum PTO Driveline Movement During Operation

Figure 1-17

22311

IMPORTANT: Avoid premature driveline breakdown.

A driveline that is operating must not exceed an

angle of 25 degrees up or down while operating 3-

point lift.

24872