24

Section 1: Assembly & Set-Up

RCF3696, RCFM3696, RCF3610, & RCFM3610 Rotary Cutters 326-600M

12/15/15

Table of Contents

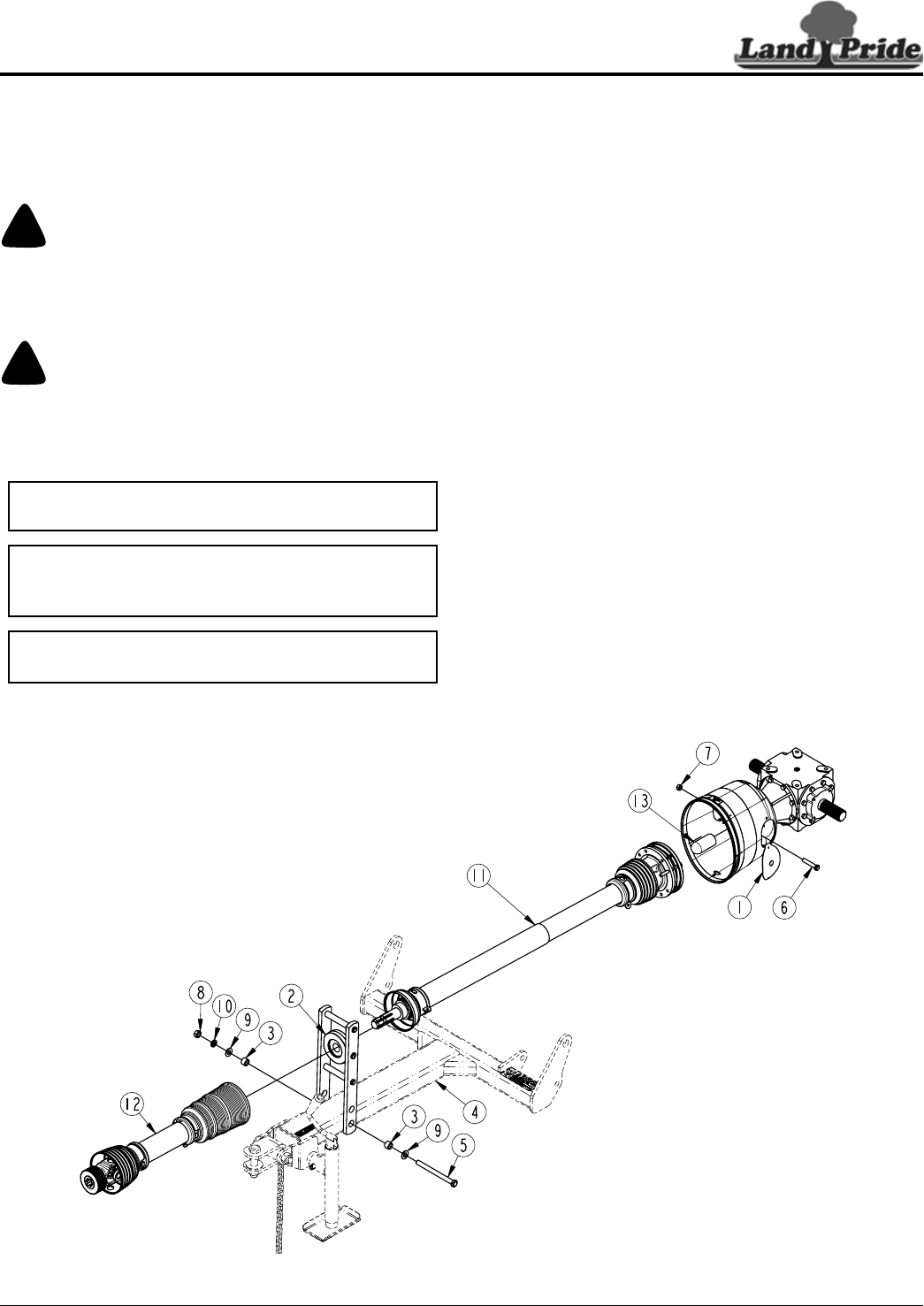

3. Remove rubber protective sleeve (#13) from gearbox

input shaft and discard.

4. Unsnap one end of gearbox shield access doors (#1)

and rotate doors open.

5. Remove conical dog pin or bolts (#6) and fastening

hardware (#7) from slip-clutch end of driveline (#11).

6. Slide slip-clutch end of driveline (#11) onto gearbox

input shaft. Make certain that the slip-clutch is fully

onto the shaft splines.

7. Attach slip-clutch end of driveline to gearbox input

shaft with existing conical dog pin or bolts (#6) and

removed hardware (#7). Tighten conical dog pin or

bolts (#6) to 45-50 ft-lb torque.

8. Push/pull on driveline yoke to be sure it is securely

fastened to the gearbox shaft.

9. Rotate gearbox shield access doors (#1) closed and

snap in place.

10. Insert jackshaft of driveline (#11) through bearing

support assembly (#2). Pull bearing support

assembly fully against driveline (#11) to extend

jackshaft splines fully through the bearing.

11. Install main driveline (#12) to jackshaft of

driveline (#11) by pulling on locking collar and

pushing driveline yoke forward onto the jackshaft

until locking collar has locked in place. Make certain

locking collar has engaged by pulling on the main

driveline.

12. Tighten set screw in bearing locking collar (#2).

Equal Angle Hitch Assembly

Figure 1-22

33946

Equal Angle Driveline

The following instructions are for installation of an

“Equal Angle Driveline”. Instructions for “Constant

Velocity Driveline” begin on page 25.

!

WARNING

Make certain all driveline yokes are securely fastened at both

ends. A loose yoke can work free allowing the driveline to

rotate uncontrollably causing machine damage and bodily

injury or death to anyone nearby.

!

WARNING

Do not use a PTO adapter. A PTO adapter will increase strain

on the tractor’s PTO shaft resulting in possible damage to

shaft and driveline. It will also defeat the purpose of the

tractor’s master shield and could cause bodily injury or death.

Refer to Figure 1-22:

1. Position bearing flange assembly (#2) on tongue

assembly (#4) with bearing locking collar facing

towards the gearbox.

2. Attach bearing flange assembly (#2) to tongue (#4)

with two 1" OD bushings (#3), two flat washers (#9),

5/8"-11 x 7 1/2" bolt (#5), lock washer (#10), and hex

nut (#8). Tighten hex nut to the correct torque.

IMPORTANT: Maximum equal angle driveline

turning angle is limited to 35 degrees.

IMPORTANT: The drivelines must be lubricated

before putting them into service. Refer to

“Lubrication” on page 49.

NOTE: .Make sure bearing locking collar is facing

rearward toward the cutter gearbox.