SECTION 1.5

ENGINE-GENERATOR PROTECTIVE DEVICES

GENERAL INFORMATION

GENERAL

Standby electric power generators will often run

unattended for long periods of time. Such operating

parameters as (a) engine oil pressure, (b) engine

temperature, (c) engine operating speed, and (d)

engine cranking and startup are not monitored by an

operator during automatic operation. Because engine

operation will not be monitored, the use of engine

protective safety devices is required to prevent engine

damage in the event of a problem.

Prepackaged generator engines mount several engine

protective devices. These devices work in conjunction

with a circuit board, to protect the engine against such

operating faults as (a) low engine oil pressure, (b) high

temperature, (c) overspeed, and (d) overcrank. On

occurrence of any one or more of those operating faults,

circuit board action will effect an engine shutdown.

LOW OIL PRESSURE SHUTDOWN:

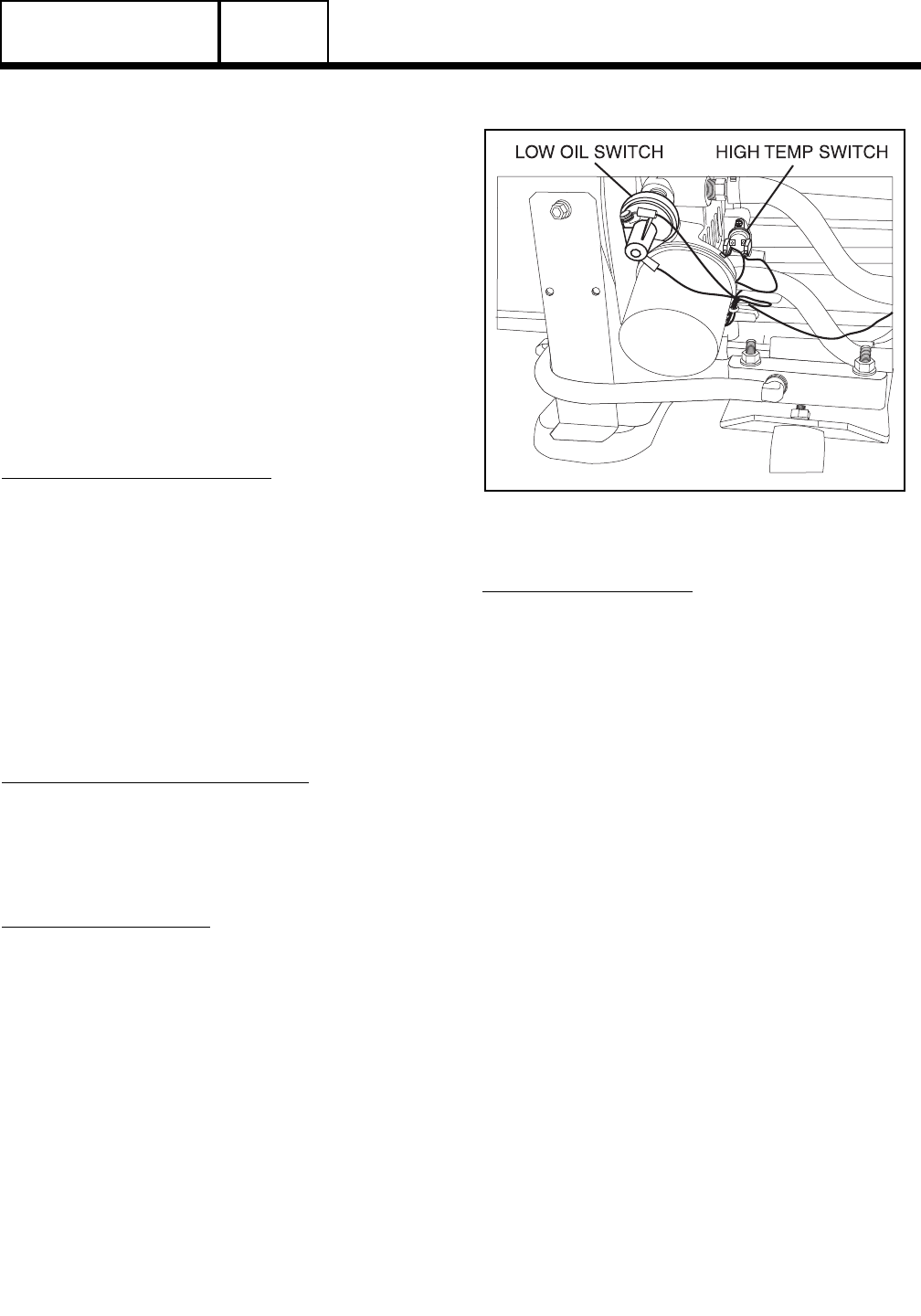

See Figure 1. An oil pressure switch is mounted on

the engine oil filter adapter. This switch has normally

closed contacts that are held open by engine oil

pressure during cranking and startup. Should oil

pressure drop below approximately 10 psi, the switch

contacts will close. On closure of the switch contacts,

a Wire 86 circuit from the circuit board will be

connected to ground. Circuit board action will then de-

energize a "run relay" (on the circuit board). The run

relay’s normally open contacts will then open and a

12 volts DC power supply to a Wire 14 circuit will then

be terminated. This will result in closure of a fuel

shutoff solenoid and loss of engine ignition.

HIGH OIL TEMPERATURE SHUTDOWN:

An oil temperature switch (Figure 1) is mounted on

the engine block. The thermal switch has normally

open contacts that will close if oil temperature should

exceed approximately 284 F (140 C). This will result

in the same action as a low oil pressure shutdown.

OVERSPEED SHUTDOWN:

During engine cranking and operation, the circuit board

receives AC voltage and frequency signals from the

generator engine run windings, via Wire 66A. Should the

AC frequency exceed approximately 72Hz (4320 rpm),

circuit board action will de-energize a "run relay"

(mounted on the circuit board). The relay’s contacts will

open, to terminate engine ignition and close a fuel shutoff

solenoid. The engine will then shut down. This feature

protects the engine-generator against damaging

overspeeds.

NOTE:

The

circuit

board

also

uses

engine

run

winding

output

to

terminate

engine

cranking

at

approximately

30

Hz

(1800

rpm).

In

addition,

the

engine

run

winding

output

is

used

by

the

circuit

board

as

an

"engine

running"

signal

The

circuit

board

will

not

initiate

transfer

of

electrical

loads

to

the

"Standby"

source

unless

the

engine

is

running

at

30

Hz

or

above.

Figure 1. Engine Protective Switches on an

Air-Cooled Engine

OVERCRANK SHUTDOWN:

Automatic engine cranking and startup normally

occurs when the circuit board senses that utility

source voltage has dropped below approximately 60

percent of its nominal rated voltage and remains at

that low level longer than fifteen (15) seconds. At the

end of fifteen (15) seconds, circuit board action will

energize a crank relay and a run relay (both relays

are on the circuit board). On closure of the crank relay

contacts, circuit board action will deliver 12 volts DC

to a starter contactor relay (SCR, for v-twin models)

or a starter contactor (SC, for single cylinder models).

The control contactor will energize and battery power

will be delivered to the starter motor (SM). The engine

will then crank.

During a manual startup (AUTO-OFF-MANUAL

switch at MANUAL), action is the same as during an

automatic start, except that cranking will begin

immediately when the switch is set to MANUAL.

Circuit board action (during both a manual and an

automatic start) will hold the crank relay energized for

15 seconds on. The relay will then de-energize for 15

seconds off. It will then energize for seven (7)

seconds on and de-energize for seven (7) seconds

off. It will repeat this same cycle for another 45

seconds.

If the engine has not started after approximately 90

seconds of these crank-rest cycles, cranking will

automatically terminate and shutdown will occur. The

circuit board uses AC signals from the stator engine

run winding as an indication that the engine has

started.

PART 1

Page 1.5-1