SYSTEM OVERVIEW

3

Control Unit Features

The control unit has the fo llowing features:

• Patented temperature compensation for chlorine output

• Programmable Microprocessor Control

• Multi-language digital display – (English, Spanish, French & German)

• Digitally controlled power to the SuperCell

• Tri-sensor Circuitry to monitor water flow, water temperature, and salt level

(and salt addition amounts to maintain 3000 ppm (3.0 g/l))

• Internal Relay for controlling an external pump or acid feeder

• On-board Diagnostic and Test programs

• Lithium battery (CR-2025) back up for clock and program settings

• ORP dry contact interface for connection to an external ORP controller.

• Electronic controller interface for Jandy®

(Versions I, K, and newer), Polaris® EOS,

or Pentair IntelliTouch® controllers.

Patented Temperature Compensation

The Tri-Sensor Assembly’s temperature sensor works in conjunction with the purifier % output to automatically adjust the

chlorine output based upon changes in the water temperature between the range of 55°F – 95°F (13°C - 35°C). As temperatures

fall lower than 75°F (24°C), the unit will activate a high purifier % lock out and may not allow purifier adjustments up to 100%.

This prevents the unit from overdriving the cell under cold temperatures, which can cause premature cell wear. At 55°F (13°C) or

colder, the unit will adjust to a fixed 1% output to prev ent the over chlorination and premature cell failure during cooler

temperatures. At 95°F (35°C) or warmer, the unit will adjust up to 100% of the normal purifier % setting to prevent under

chlorination during warmer temperatures.

The Temperature Compensation feature is not needed and is therefore automatically disabled when the Pool Pilot Digital (model

#75003) is installed as a part of the Digital TC Total Control System (in conjunction with AutoPilot’s Pool Chemistry Controller -

# 75001)

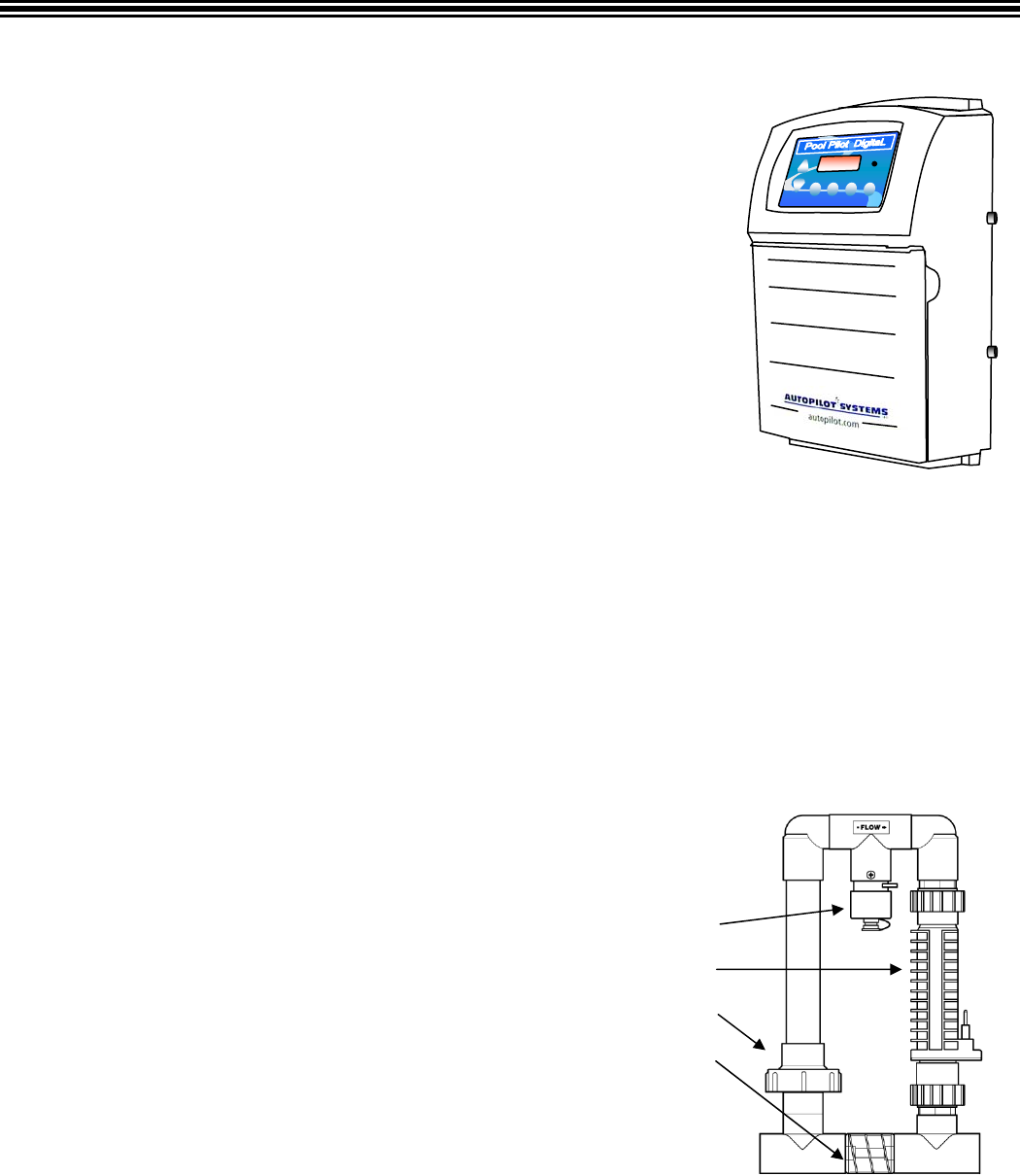

Patented Automatic-Flow Bypass Manifold Assembly

The manifold is connected into the pool plumbing. Water from the

pool is circulated though the manifold by the circulation/filter pump.

The manifold’s four key components are the strainer screen,

Tri-Sensor, Su perC el l , a nd by pass fl o w val v e.

The strainer screen prevents debris in the water from entering the

Tri-Sensor or SuperCell and requires periodic inspection and cleaning.

The Tri-Sensor provides data (from electronic sensors) to the Control

Unit for monitoring water flow, water temperature, and salt level

through the cell. The Control Unit will use this data to determine if

the conditions are safe for the SuperCell to operate.

The SuperCell receives power from the Control Unit and converts

the salt water to chlorine.

The Bypass Flow Valve allows water flow rate to be optimized

through the Sup e rCell. The slower water flow through the SuperCell

results in a more efficient “Super-Chlorination effect” in the cell that

results in better overall sanitization results.

Tri-Sensor

SuperCell

Strainer Screen

Bypass Flow Valve

CHECK

SYSTEM

BOOST MENU SELECT PUMP