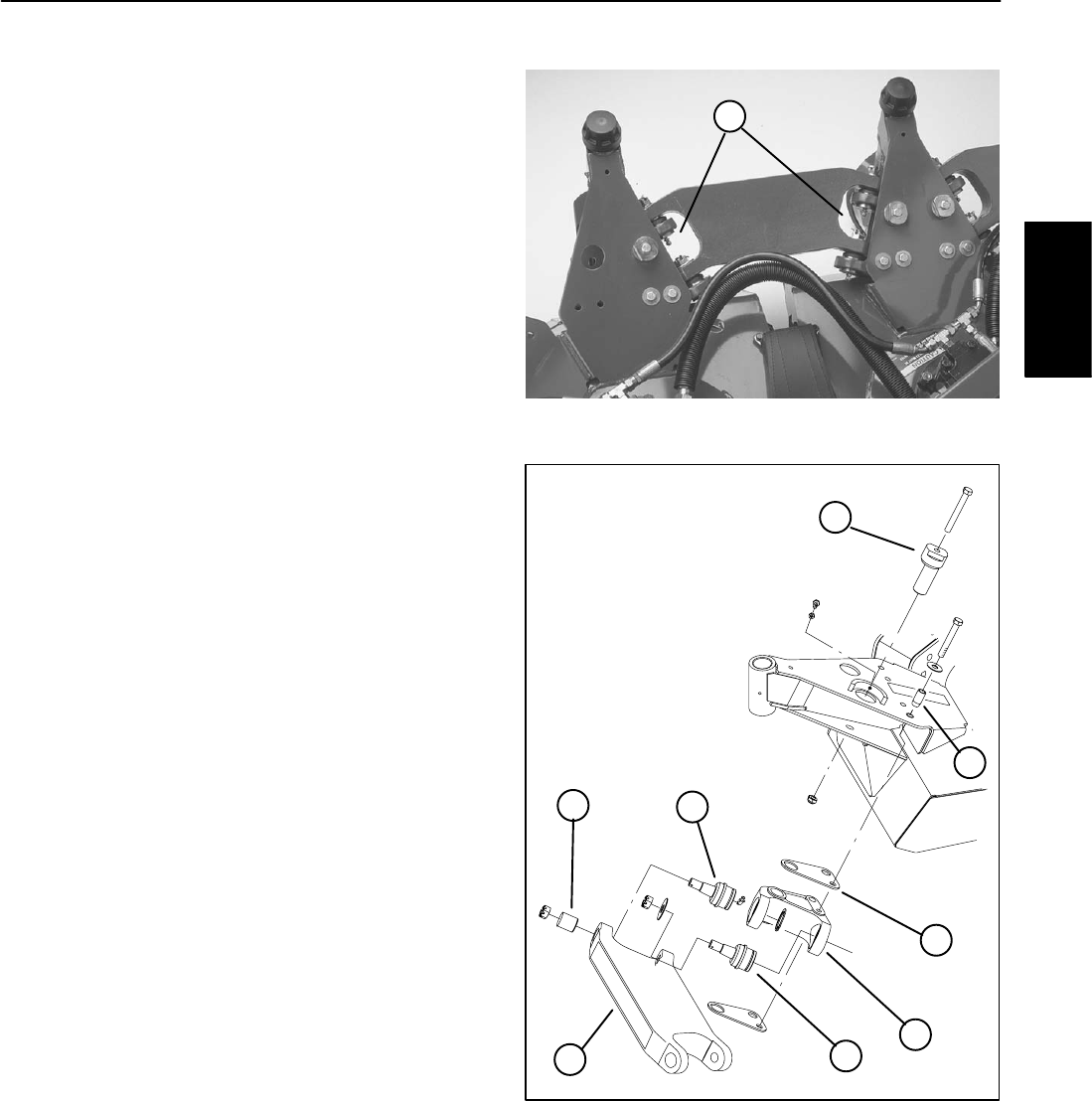

Chamber Pivot Service

If cutting unit chamber pivot assemblies should ever

have to be separated for service or repair, use the follow-

ing procedure.

1. Pivot assembly dis–assembly.

A. Remove capscrews and nut from pivot cast-

ing.

B. Loosen capscrew locking eccentric cam in

place.

C. Using a 1/2 inch (13 mm) diameter drive pin,

drive pilot pin 3/8 inch (10 mm) to 1/2 inch (13 mm)

into pivot casting.

D. Slide pivot assembly out of chamber housing.

1

2. Ball joint removal from pivot assembly

Figure 23

A. Remove the lock nuts from the ball joint studs.

1. Chamber pivots

B. Separate span casting from ball joints, Using

an expansion fork and soft (lead) hammer.

C. Slide tapered sleeve out of span casting. and

save this part.

D. Remove retaining rings from back side of ball

joints.

E. Using a press, push ball joints out of pivot cast-

ing. The front (top) ball joint should be removed

first.

1

3

4

4

5

6

7

Figure 24

1. Pivot casting 5. Span casting

2. Pivot pin 6. Tapered sleeve

3. Eccentric cam 7. Pivot spacer (2)

4. Ball joint

Contour 82

Cutting Unit

Groundsmaster 3000/3000–D

Page 10 – 15

Contour 82 Cutting Unit

2