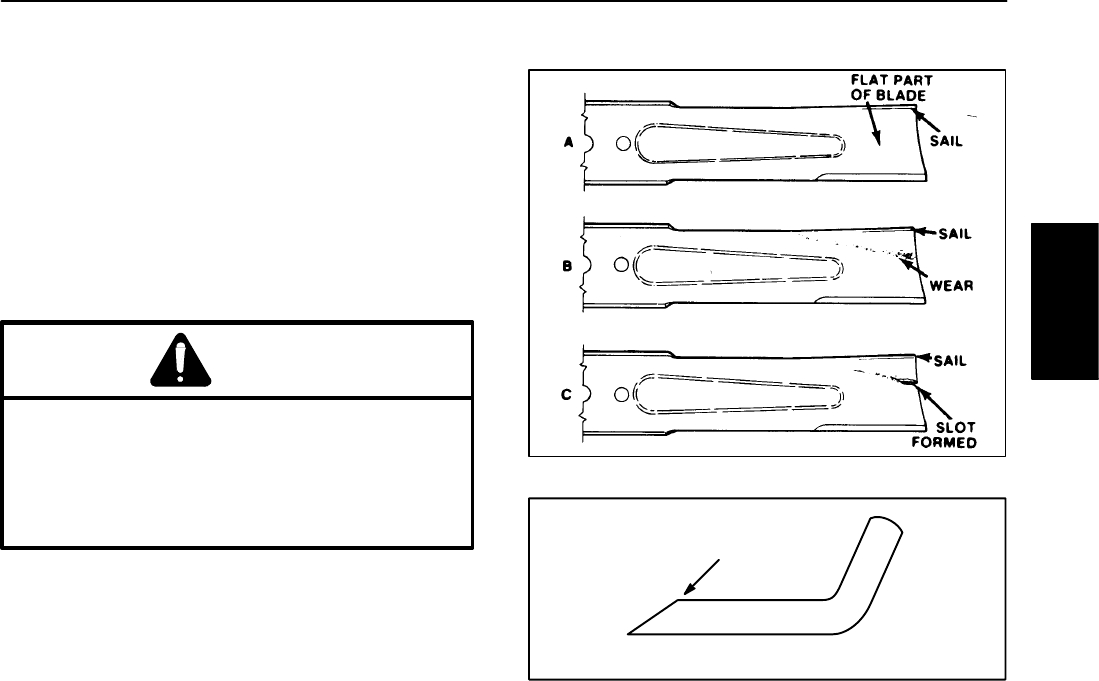

Inspecting and Sharpening Blade

1. Lock transport levers, raise cutting unit to highest

position, shut the engine off and engage the parking

brake.

2. Examine cutting ends of the blade carefully, espe-

cially where the flat and curved parts of the blade meet

(Fig. 21–A). Since sand and abrasive material can wear

away the metal that connects the flat and curved parts of

the blade, check the blade before using the machine. If

wear is noticed (Fig. 21–B), replace the blade: refer to

Removing Cutter Blade.

DANGER

between the sail and flat part of the blade

If blade is allowed to wear, a slot will form

(Fig. 21–C). Eventually a piece of the blade

may break off and be thrown from under the

housing, possibly resulting in serious injury to

yourself or bystander.

3. Inspect cutting edges of all blades. Sharpen the cut-

ting edges if they are dull or nicked. Sharpen only the top

of the cutting edge and maintain the original cutting

angle for best performance (Fig. 22). The blade will re-

main balanced if same amount of metal is removed from

both cutting edges.

4. To check blade for being straight and parallel, lay

blade on a level surface and check its ends. Ends of

blade must be slightly lower than the center, and cutting

edge must be lower than the heel of the blade. This

blade will produce good quality of cut and require mini-

mal power from the engine. By contrast a blade that is

higher at the ends than the center, or if cutting edge is

higher than the heel, the blade is bent or warped and

must be replaced.

5. Install blade retainer, blade (sail facing (up) toward

cutting unit) with anti–scalp cup and blade bolt. Tighten

blade bolt to 85–110 ft–lb (12 – 15 Kgm).

Figure 21

END VIEW

SHARPEN AT THIS

ANGLE ONLY

Figure 22

Contour 82

Cutting Unit

Groundsmaster 3000/3000–D

Page 10 – 13

Contour 82 Cutting Unit