4-10

435/485/535

F4-67

F4-9

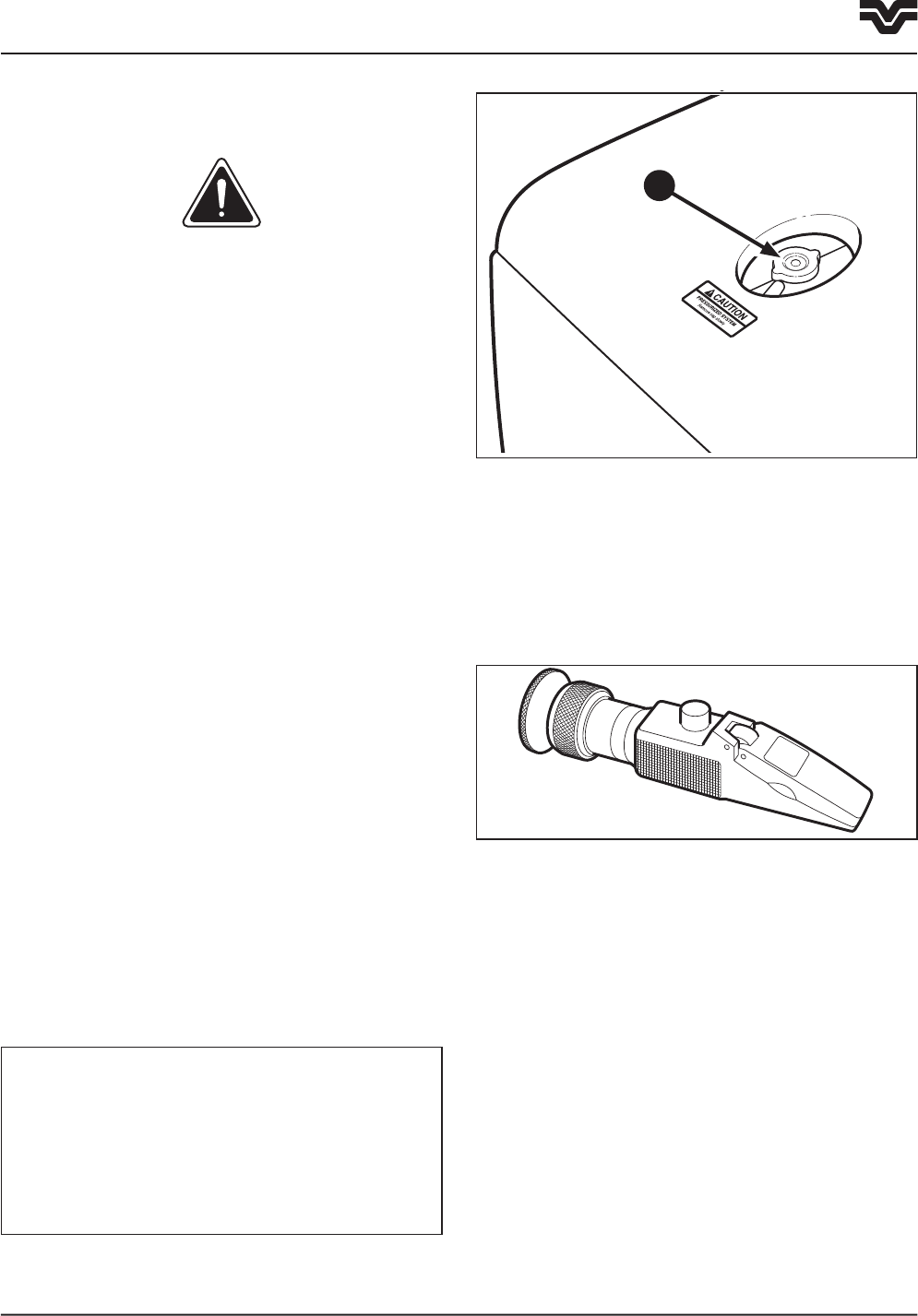

If the engine coolant is low, add coolant through the

radiator cap (1) accessed on top of the hood.

CAUTION: THE COOLING SYSTEM OPERATES

UNDER PRESSURE WHICH IS CONTROLLED BY

THE RADIATOR CAP. IT IS DANGEROUS TO REMOVE

THE CAP WHILE THE SYSTEM IS HOT. ALWAYS

TURN THE CAP SLOWLY TO THE FIRST STOP

AND ALLOW THE PRESSURE TO ESCAPE BEFORE

REMOVING THE CAP ENTIRELY. WEAR GLOVES

WHEN REMOVING THE CAP.

The coolant added to the engine must meet specific

requirements. Use a low silicate antifreeze which meets

Engineering Standard GM 6038-M, or which contains

no more than 0.1% anhydrous alkali metasilicate and

meets either Engineering Standard GM 1825-M or

GM 1899-M, which are performance specifications.

NOTE: Factory fill is a fully formulated coolant mixture

(pink in color). Propylene or ethylene glycol can be

mixed in the cooling system.

Use soft water in the coolant mixture. Contaminants

in hard water neutralize the corrosion inhibitor

components. Water must not exceed 300 ppm

hardness, or contain more than 100 ppm of either

chloride or sulphate.

Antifreeze

Antifreeze must be used in any climate for both

freeze and boiling point protection. Cummins Engine

Company, Inc. recommends a 50% concentration level,

40% - 60% range of ethylene glycol or propylene glycol

in most climates. Antifreeze at 68% concentration

provides the maximum freeze protection and must

never be exceeded under any condition. Antifreeze

protection decreases above 68%.

Section 4 - Lubrication & Maintenance

Every 10 Hours or Daily

1

NOTE: Propylene glycol antifreeze protection levels

CANNOT be checked using the same hydrometer as

would be used with ethylene glycol antifreeze.

You must check the concentration level using a

refractometer. Both propylene and ethylene glycol

protection levels (of a mixture of both) can be measured

with the refractometer (P/N: CC2806).

Once the protection level of the coolant is decided

(ratio of water to antifreeze), the mixture must contain

one unit of Cummins DCA4 (dry chemical additive)

per gallon of coolant. A DCA unit is equal to 42.5

g (1.5 dry ounces) or120 ml (4 liquid ounces). Your

Buhler Versatile dealer can assist you in obtaining the

DCA4 additive.

IMPORTANT: Failure to maintain DCA4 in the cooling

system will cause cooling system corrosion and engine

failure.

IMPORTANT: The concentration of DCA4 should be

checked with a test kit, available from Cummins /

Fleetguard or through your Buhler Versatile dealer

(P/N: CC2602).

IMPORTANT: Do not add cold coolant to a hot engine.

Engine castings can be damaged. Allow the engine to

cool to below 50° C (120° F).

Ethylene Glycol Propylene Glycol

40% -23°C (-10°F) -21°C (-6°F)

50% -37°C (-34°F) -33°C (-27°F)

60% -54°C (-65°F) -40°C (-56°F)

68% -71°C (-90°F) -63°C (-82°F)