3-86

435/485/535

Section 3 - Operation

Hydraulic Operation - Electro-hydraulic

F3-109

ON

N

N

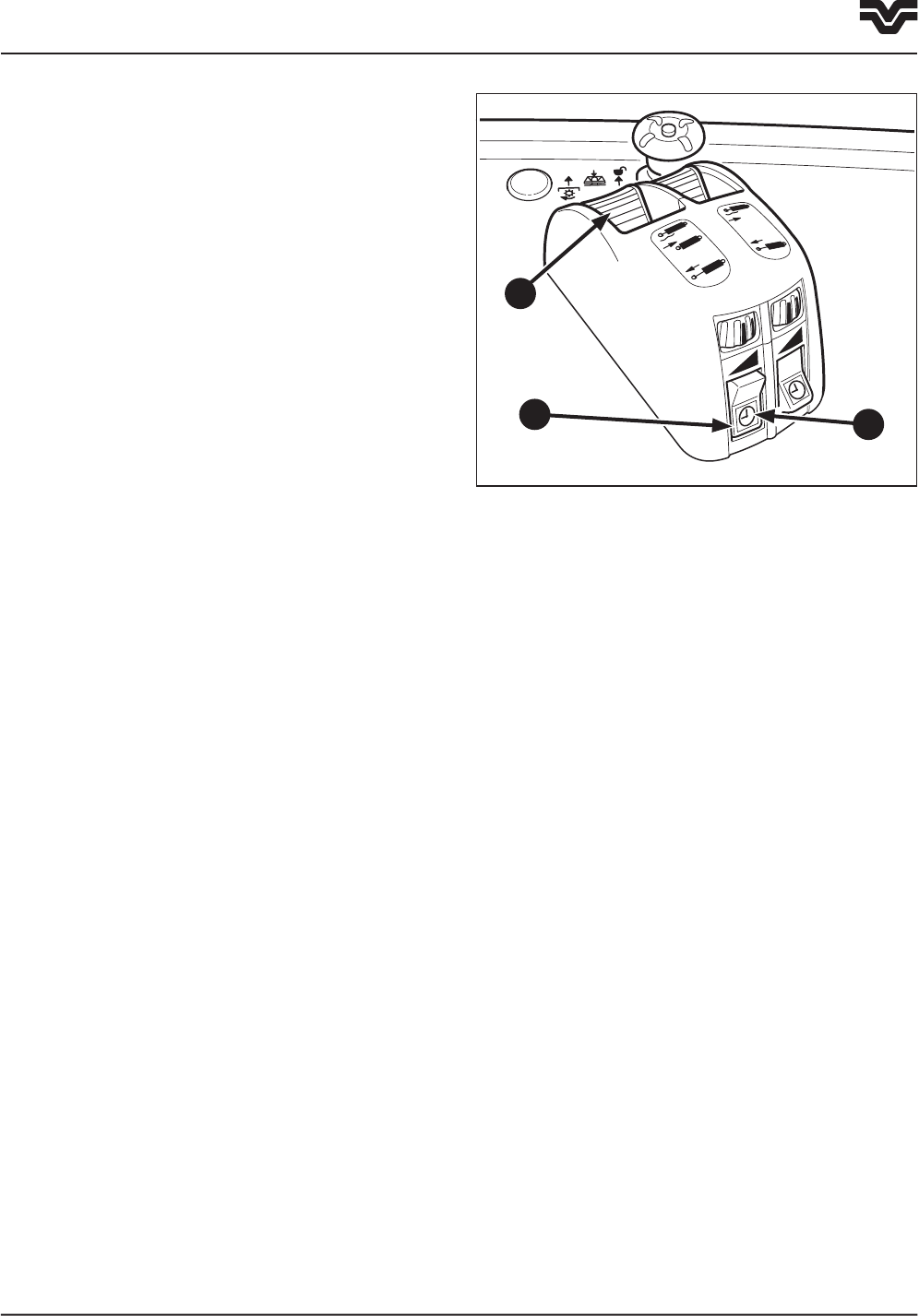

Programming of the lever can be performed in either

sequence, extend/retract, retract/extend or one

sequence only, extend or retract. The program for the

individual lever (2) will remain the same even when

the engine is stopped and the ignition switch is in

the off position, as long as the programming switch

(1) remains in the program position as shown. The

maximum allowable time limit for any programmed

timed operation is two minutes.

Programming the lever with the engine and hydraulic

flow off is possible however accuracy of actual operation

will be marginal. Whenever a hydraulic application is

changed, the lever should be reprogrammed to suit

the new operation.

When operating in the timed programmed mode,

feathering of the hydraulic flow is possible by

moving the lever variably anywhere between the

neutral position and the fully opened position.

The timed operation sequence only begins once

the lever has been locked in the fully opened

position.

Should the lever be moved to the float position no

timed program is possible and the lever must be

returned back to neutral manually.

When the bottom of the switch is depressed, light (3)

in the switch will begin to flash. This is an indication

to the operator that a timed sequence must be

programmed into the EHR controller. The light will

continue to flash for ten seconds to allow time for the

operator to begin the programming sequence.

If a program is not started within this ten second

period, the controller will not accept any sequence and

the remote control lever (2) will not remain latched in

either the extend or retract positions.

To program the EHR system, first ensure that the

cylinder hydraulic hoses are properly connected to the

appropriate rear remote valve. Start the tractor engine

and ensure the EHR engagement switch is up/on.

Set the tractor engine RPM’s at the normal operating

speed in which the cylinder is to be operated. This is

important as the programming of the control levers is

based on a time interval to correspond to the time it

takes the cylinder ram to extend as well as retract. Any

change in engine rpm will have an effect on hydraulic

flow (GPM) and therefore the time it takes the cylinder

to extend and retract. The control lever timed program

always remains the same regardless of oil flow (GPM)

until reprogrammed. Therefore consistent operation is

required for the system to operate correctly. Using the

corresponding color coded programming switch (1)

depress the bottom of the switch so light (3) begins to

flash. While the light is flashing use control lever (2)

to extend the cylinder. As soon as the control lever is

activated the programming light will go on solid. Hold

the lever until the cylinder is extended to the desired

position and then return the lever to the neutral

position. When the lever is returned to the neutral

position the programming light will once again begin

to flash indicating that the retract phase of the cycle

needs to be programmed.

Next use lever (2) to retract the cylinder. As soon as

the lever is activated the programming light will go

on solid. Hold the lever until the cylinder is retracted

to the desired position and then return the lever to

the neutral position. After the second phase has been

completed the programming light will go out indicating

that the programming has been memorized. The lever

timed operation is now programmed for the extend

and retract operation of the cylinder.

Repeat the above sequence to program the remaining

levers.

1

2

3