Workman MDX--DPage 4 -- 34Drive Train

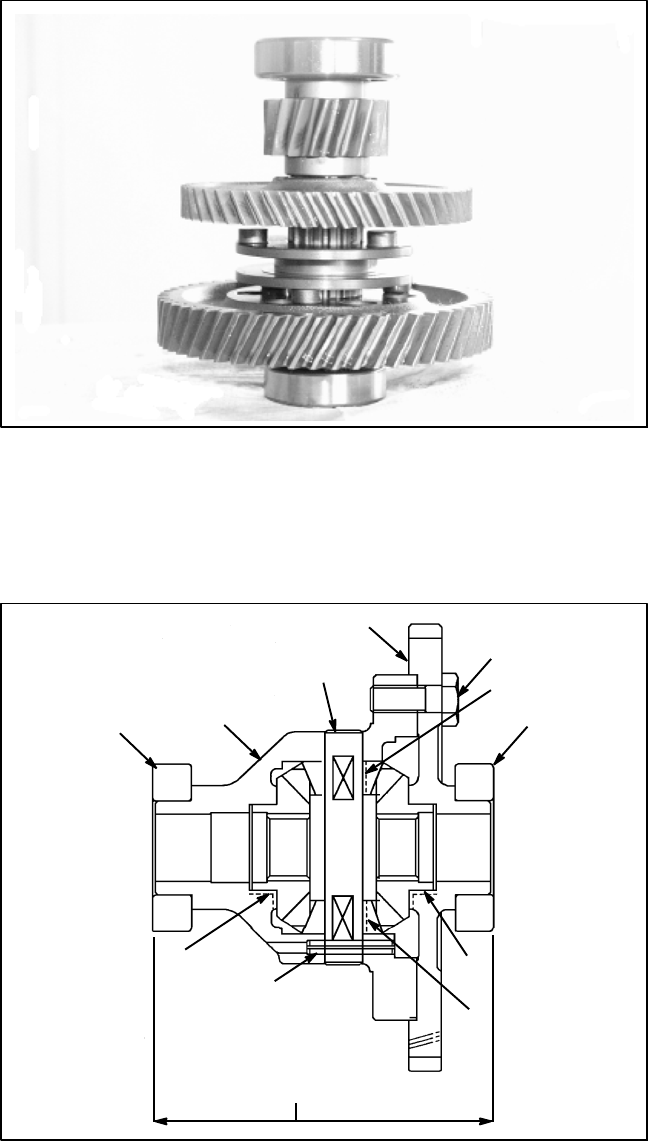

Figure 41

D. The center shaft should appear as above when

assembled.

3. Assemble differential assembly.

1. Pinion gear (greased surface)

2. Pinion shaft

3. Side gear (greased surface)

4. Differential case

5. Gear 62

6. Bolt

7. Spring pin

8. Ball bearing

9. Ball bearing

Figure 42

8

3

7

1

9

1

6

5

2

4

3

(123.3 to 124.0 mm)

4.854” to 4.882”

A. Apply molybdenum disulfide grease to the inside

of both pinion gears where they contact the pinion

shaft. Apply molybdenum disulfide greaseto the out-

side of both side gears where they contact the differ-

ential case and gear 62.