Workman MDX--D Page 6 -- 17 Chassis

Disassembly (Fig. 11)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition.

WARNING

Before jackingup the machine,review andfollow

Jacking Instructions in Chapter 1 -- Safety.

2. Chock wheels not being jacked up. Jack front wheel

off the ground and support vehicle with appropriate jack

stand beneath the frame.

3. Remove lug nuts and pull wheel assembly from ma-

chine.

4. Remove brake caliper from spindle (see Front Brake

Caliper inthissection). Positioncaliper away from wheel

hub and spindle.

5. Carefully pry dust cap from wheel hub.

6. Remove cotter pin and nut retainer from spindle.

7. Remove jam nut that secures wheel hub to spindle.

Slide wheel hub with bearings and brake rotor from

spindle.

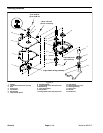

8. Disassemble the wheel hub (Fig. 12):

A. Pull the seal out of the wheel hub.

B. Remove bearings from both sides of the wheel

hub. Clean bearings in solvent. Make sure bearings

are in good operating condition. Clean the inside of

the wheel hub. Check the bearing cups for wear, pit-

ting or other noticeable damage. Replace worn or

damaged parts.

C. If necessary, remove wheel studs and brake rotor

from wheel hub.

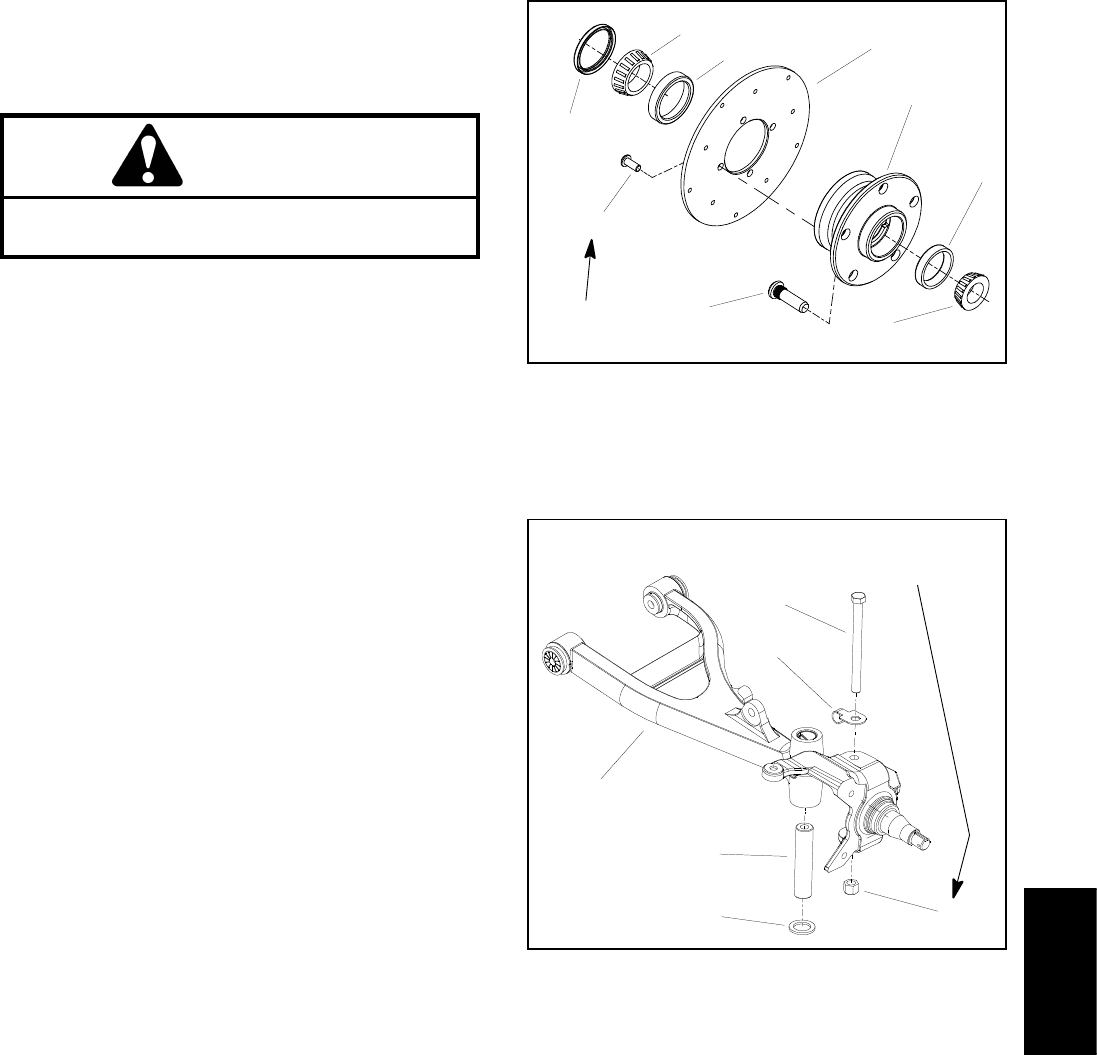

9. Remove spindle (Fig. 13):

A. Remove cotter pin and castle nut securing tie rod

ball joint to the spindle. Separate ball joint from the

spindle. Remove tie rod from steering gearbox pit-

man arm if necessary.

B. Remove lock nut and cap screw securing the

spindle to the A--arm. Separate spindle from A--arm.

C. Locate and remove thrust washer from bottom of

kingpin sleevein A --arm and brake hoseclip from top

of A--arm. Remove kingpin sleeve from A--arm ifnec-

essary.

1. Outer bearing cone

2. Outer bearing cup

3. Wheel hub

4. Brake rotor

5. Inner bearing cup

6. Inner bearing cone

7. Seal

8. Socket screw (4 used)

9. Wheel stud (5 used)

Figure 12

1

2

3

4

5

6

7

8

9

9to11ft--lb

(13 to 14 N--m)

1. Cap screw

2. Brake hose clip

3. A--arm (LH shown)

4. Kingpin sleeve

5. Thrust washer

6. Lock nut

Figure 13

1

2

3

4

56

75 to 100 ft--lb

(102 to 135 N--m)

Assembly (Fig. 11)

1. Install spindle as follows (Fig. 13):

A. Make sure king pin sleeve is positioned into the

pivot hub of the A--arm. Sleeve must extend through

the bottom of the hub.

B. Place thrust washer onto the bottom of the king

pin sleeve. Then place spindle over the A--arm hub,

king pin sleeve and thrust washer.

NOTE: Make sure cap screw is inserted down

through the spindle and A--arm hub.

Chassis