Workman MDX--D Page 6 -- 21 Chassis

A--arm Removal (Fig. 15)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

WARNING

Before jackingup the machine,review andfollow

Jacking Instructions in Chapter 1 -- Safety.

2. Chock wheels not being jacked up. Jack front wheel

off the ground and support vehicle with appropriate jack

stand beneath the frame.

3. Remove front wheel and spindle from A--arm (see

Lower Steering and Front Wheel Removal in this sec-

tion).

4. Remove cap screw (item 7), flat washer (item 5) and

lock nut (item6) thatsecurelower end ofshockabsorber

to A--arm.

5. Support A--arm to prevent it from falling.

6. Remove both cap screws (item 19) and lock nuts

(item 6) that secure A--arm to frame. Pull A--arm from

frame.

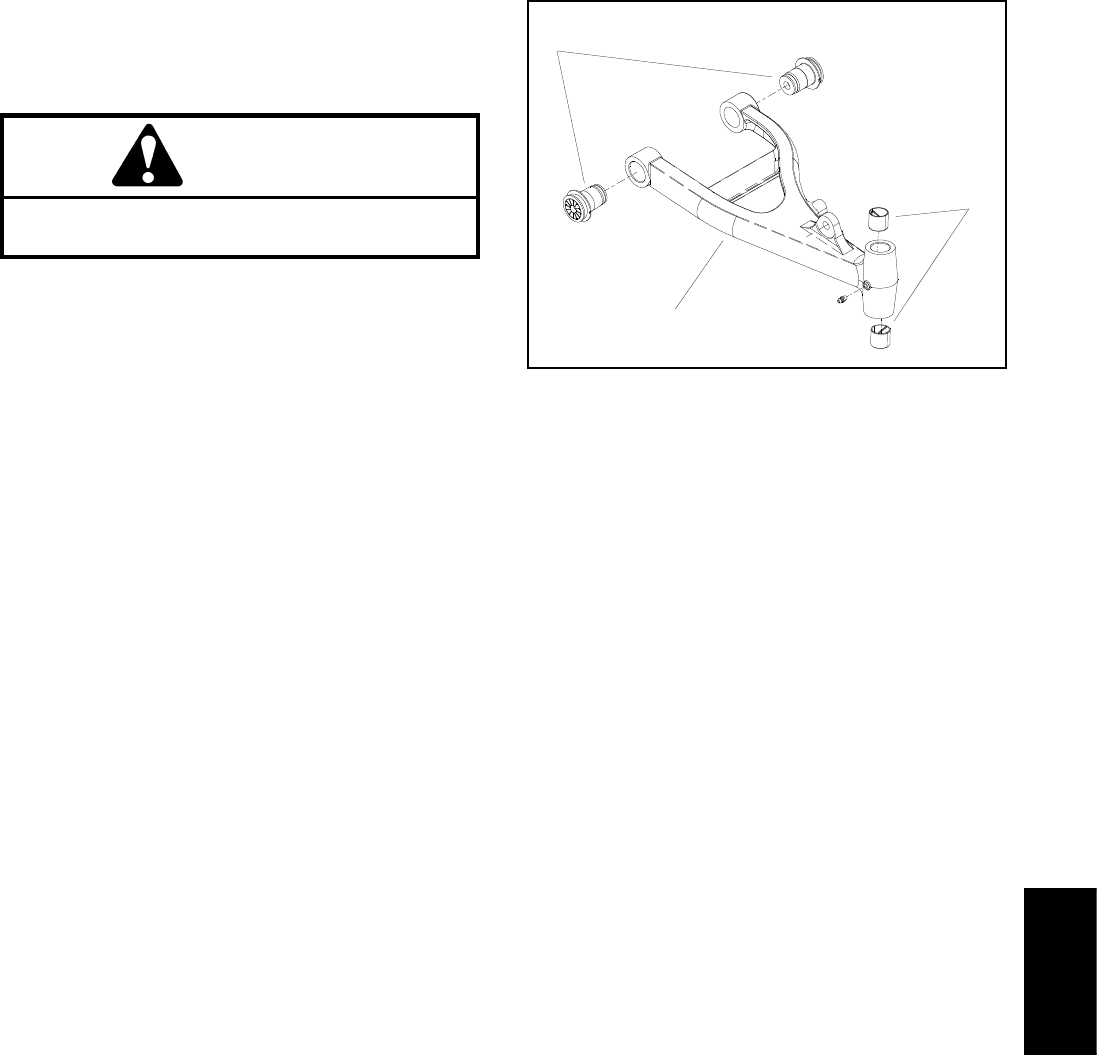

7. If necessary, remove flange bushings and straight

bushings from A--arm bores (Fig. 16).

A--arm Installation (Fig. 15)

1. If bushings were removed from A--arm, press new

bushings fully into bore of A--arm (Fig. 16).

2. Position A--arm to the frame. Secure A--arm to the

frame with cap screws (item 19) and lock nuts (item 6).

Insert front screw from front of machine and rear screw

from rear of machine. Do not fully tighten nuts.

3. Position lower end of shock absorber to A--arm and

insert cap screw (item 7) with flat washer (item 5) from

rear of shock. Secure wit h lock nut (item 6).

4. F ully tighten lock nuts (item 6) to secure A--arm to

machine frame.

5. Install spindle and front wheel to the A--arm (see

Lower Steering and Front Wheel Installation in this sec-

tion).

6. Lower machine to ground. Make sure that wheel lug

nuts are properly torqued in a crossing pattern from 80

to 90 ft--lb (109 to 122 N--m).

7. Align front wheel toe--in (see Adjust Front Wheel

Toe--in in the Adjustments section of this chapter).

1. A--arm

2. Flange bushing

3. Straight bushing

Figure 16

2

3

1

Chassis