Workman MDX--DPage 3 -- 16Diesel Engine

11.Disconnect electrical connections from the following

engine components:

A. Disconnect main wire harness connections to

glow plug bus, temperature sender and engine run

solenoid (Fig. 14).

B. Disconnect main wire harness connection to f us-

ible link harness.

C. Disconnect engine wire harness connector from

themainwireharness.Theenginewireharnessin-

cludes connectors for the alternator, oil pr essure

switch, starter solenoid and engine ground.

D. Remove flange head screw from front engine

mount that secures negative battery cable and en-

gine ground connector. Make sure to notelocation of

lock washer when removing screw. Position negat-

ive battery cable away from engine.

12.Remove four (4) flange nuts, spacers, snubbing

washers and cap screws that secure the engine to the

engine mo unts.

CAUTION

Make sure that hoist or liftused toremove engine

can properly support engine. Engine assembly

weighs approximately 170 pounds (77 kg). Also,

one person should operate the hoist while a

second person guides the engine out of the

vehicle.

13.Remove engine from the vehicle.

A. Attach a short section of chain between both en-

gine lift tabs.

B. Connect hoist to center of chain.

IMPORTANT: Make sure to not damage the en-

gine, fuel hoses,electrical harness orother parts

while removing the engine.

C. Carefully move the engine assembly away from

the radiator and when the engine has cleared the ra-

diator shrouds, carefully raise the engine from the

vehicle.

14.Remove engine brackets, components and attach-

ments as necessary to repair the engine.

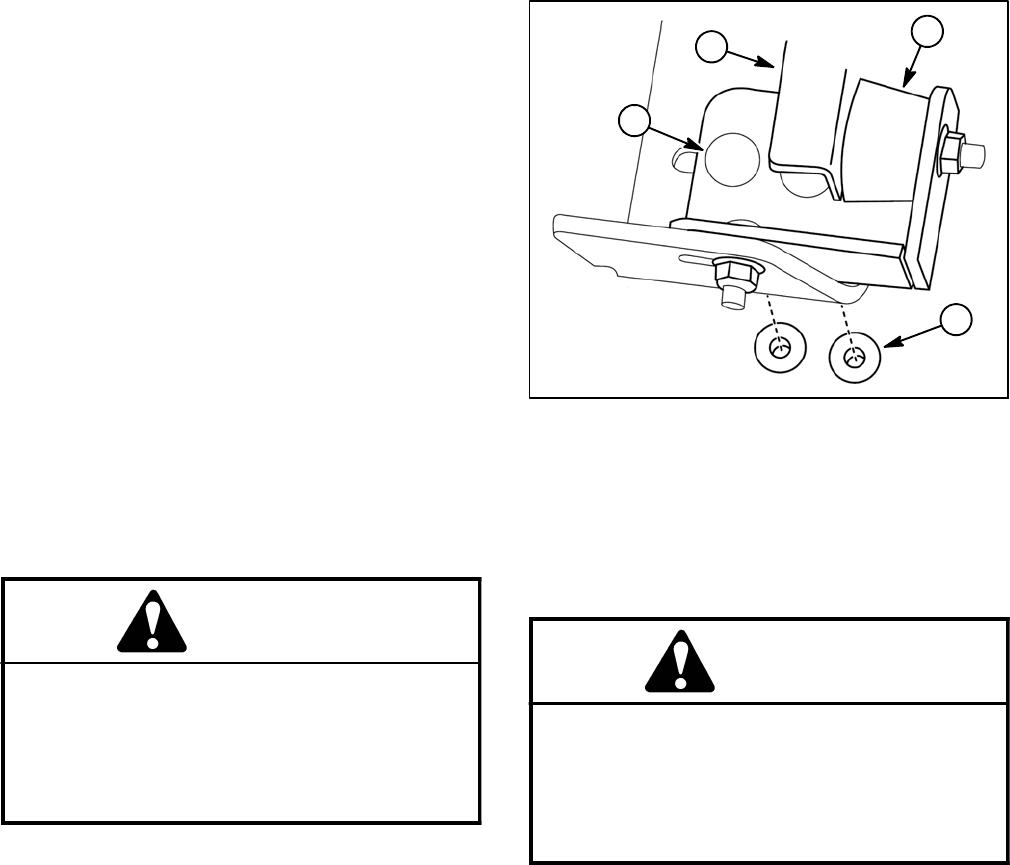

15.Inspect engine mounts (Fig. 15) and bumper as-

sembly (Fig. 16) for wear or damage and replace com-

ponents if necessary.

Figure 16

1. Front engine bracket

2. Rubber bumper

3. Lock nut (3 used)

4. Carriage screw (3 used)

3

1

2

4

Engine Instal lation (Fig. 12)

1. Install all removed mounts, components and attach-

ments to the engine.

CAUTION

Make sure that hoist or lift used to install engine

can properly support engine. Engine assembly

weighs approximately 170 pounds (77 kg). Also,

one person should operate the hoist while a

second person guides the engine into the

vehicle.

2. Install engine to the vehicle.

A. Attach a short section of chain between both en-

gine lift tabs.

B. Connect a hoist at the center of the short section

of chain.

IMPORTANT: Make sure to not damage engine,

fuel lines, electrical harness or other parts while

installing the engine.

C. Carefully lower engine assembly into the engine

area of the vehicle. Align holes in engine brackets

with engine mounts attached to frame.

3. Secure engine to engine mounts with four (4) cap

screws, snubbing washers, spacers and flange nuts.