Workman MDX--DPage 4 -- 14Drive Train

Driven Clutch

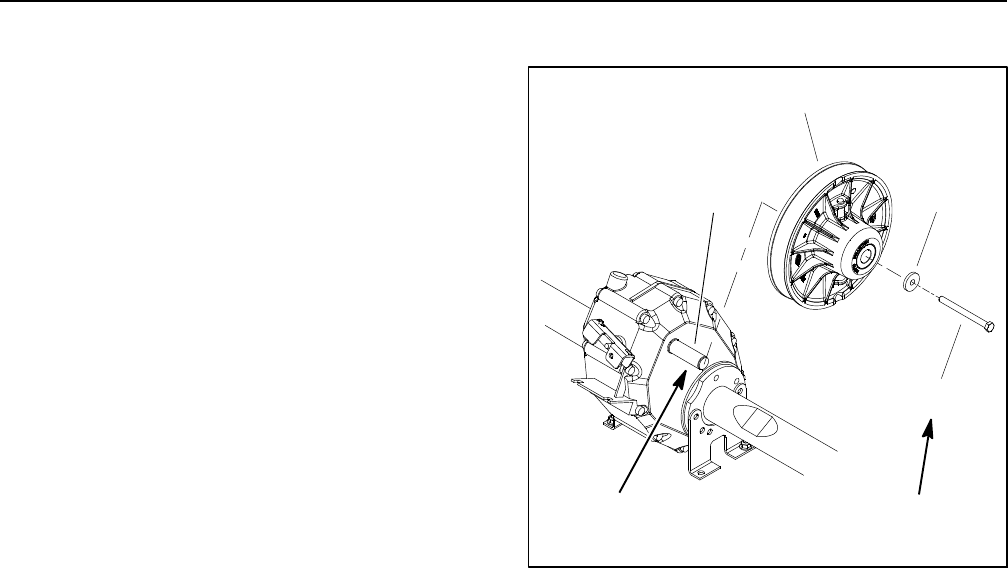

Driven Clutch Removal (Fig. 13)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

Raise and support cargo box.

2. Remove muffler from the vehicle (see Exhaust Sys-

tem in the Service and Repairs section of Chapter 3 --

Diesel Engine).

3. Carefully remove drive belt from the driven clutch.

4. Remove cap screw and stepped washer securing

the driven clutch to the input shaft of the transaxle.

5. Slide driven clutch from the transaxle input shaft.

Driven Clutch Installation (Fig. 13)

1. Coat transaxle input shaft with antiseize lubricant.

2. Position driven clutch to the input shaft. Make sure

pulley side of the clutch is next to the transaxle case.

3. Secure driven clutch to the transaxle input shaft with

cap screw and stepped washer. Torque cap screw from

39 to 47 ft--lb (53 to 63 N--m).

4. Install drive belt to the driven clutch.

5. Install muffler to the vehicle (see Exhaust System in

the Service and Repairs section of Chapter 3 -- Diesel

Engine).

6. Lower and secure cargo box.

1. Cap screw

2. Stepped washer

3. Driven clutch

4. Input shaft (transaxle)

Figure 13

3

2

Antiseize

Lubricant

4

1

39 to 47 ft --lb

(53 to 63 N--m)